8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Share

Read Next

3D printing has a long history in the plastics industry, but in recent years the technology has greatly expanded and accelerated in its application by plastics processors. Today molders, moldmakers and OEMs alike are turning to additive manufacturing (AM) to save time, serve new markets and even fill supply chain gaps.

Here are eight ways that 3D printing is currently being applied in the plastics industry.

1. Mold Tooling

Lead time delays for molded parts often originate from difficulties with sourcing tooling. 3D printing makes it possible to accelerate mold development and simplify design changes down the line. If a new design is needed, 3D printing offers a faster route to a new tool and even the chance to repair or modify an existing one. While metal 3D printing methods, such as laser powder bed fusion, have historically been the most common techniques applied to mold tooling, there are new innovations to explore in terms of more accessible metal printing methods and short-run molds made from other materials such as polymer composites.

The clear model in the center shows the conformal cooling lines inside the metal 3D printed mold on the right, used to produce the plastic part on the left.

2. Robot End Effectors

Cobots, pick-and-place robots and other automation can make plastics processing more productive, but in most cases these additions require specialized end-of-arm tooling (EOAT) and other fixturing. 3D printing can be applied to produce vacuum grippers and other specialized end effectors for handling parts. These devices can integrate vacuum lines, wire harnesses and other features to simplify assembly, and tend to be lighter weight than conventional options.

This 3D printed EOAT incorporates air lines for vacuum and pressure into its design.

3. Fixtures

3D printed nests for CMM inspection can be created using the part’s existing CAD model, similar to the process for designing a mold.

Affordable desktop 3D printers make it possible to create affordable items for plant use such as inspection fixtures, assembly tools and check gages. CMM nests, for example, can be developed using mold design tools to generate the inverse of the part and arrive at a 3D-printable fixture design. As an added bonus, once fixtures have been developed for 3D printing, they can be saved as digital files. Should one be damaged or go missing, it can be quickly replaced by simply printing another.

4. Prototyping and Product Development

3D printing still plays a valuable role for rapid prototyping, as it is often the fastest way to get a look-and-feel prototype or iterate design ideas. However, the technology has advanced to the point that, with the right material and printer, a prototype can often be used just like a production part. Brackets, electronics enclosures, ducts, components of medical devices and more have made this leap.

These smart ski goggles were developed with a 3D printed electronics enclosure. Originally meant as a prototype, the 3D printed assembly has since been used in sale units as well.

5. Bridge Production

This air diverter for a youth motorbike was designed for injection molding, but bikes produced before the mold tooling was ready used 3D printed parts like this.

The need for tooling adds automatic lead time to producing a new molded part, but 3D printing can enable a manufacturer to jump straight into production while waiting for that tooling. This means that new products can be launched into the marketplace sooner, and brand owners can get feedback before committing to the expense of a mold. The bridge need not start at the beginning of a product’s life span, either — many companies are now turning to 3D printing to bridge gaps due to supply chain disruptions as well.

6. Mass Customization

The digital nature of 3D printing makes it possible to easily adjust a base product design via software to suit the specific customer or application. The technology can be applied to produce everything from custom medical devices such as splints and hearing aids to consumer products like shoe insoles and sporting equipment tailored to the buyer.

3D printing makes it possible to support custom geometry and tweaks to a product design like a forearm cast, so that each part can be tailored to the user.

7. Digital Inventory

These autobody clips are 3D printed on demand in groups as an alternative to storing extras in physical inventory.

Files for 3D printing are more easily stored than physical parts, leading major OEMs, military branches and government agencies to adopt the technology as a way of sourcing spare parts and items needed for system maintenance. Digital inventory parts like clamps, clips and brackets can be 3D printed as needed, saving the hassle and expense of storing extras or keeping track of tooling. Even better, digital inventory can also be distributed. By working with manufacturing partners or placing printers at different facilities, organizations can produce these parts near where they will be used.

8. Serial Production

3D printing is a viable production choice for a variety of products, particularly where printing enables geometric complexity or other advantages. While 3D printing is capable of continuous production of tens of thousands of pieces, it is equally applicable to smaller batches of parts needed less frequently — with no minimum order quantity. Production use cases for this technology include brackets, phone cases, valves, medical implants, packaging solutions and much, much more.

These phone case components are 3D printed in a machine that can produce several hundred of these parts per day; scaling production to higher quantities means simply adding additional machines.

Related Content

Do Distributors Dream of Digital Inventory? Würth Additive Group Does

It’s more than a dream for Würth Additive Group and its parent company, in fact. Along with supplying additive equipment, the group is now developing solutions for sourcing 3D printed parts in a reliable, elastic digital inventory model.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read More3D Printed Replacement Clamp for an F-16 Aircraft: The Cool Parts Show #54

3D printing is a valuable addition to sustainment programs, but only if printed parts can be qualified as fast and flexibly as they can be made. In this episode of The Cool Parts Show, we look at the clamp that won the Air Force’s Approval Sprint Challenge designed to address this need.

Read More3D Printed Spares, Electrification and Cool Parts: Top 10 Stories of 2022: AM Radio #31

Our top articles and videos from 2022 reflect increasing use of additive manufacturing for replacement parts; growing applications for electric motors; and a maturing user base. Read through the top 10 list or listen to the AM Radio podcast episode all about these stories.

Read MoreRead Next

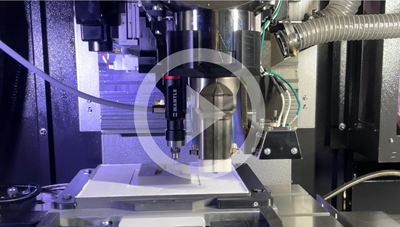

3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreRekkie AR Ski Goggles Made Possible With 3D Printing: The Cool Parts Show #53

When the electronics enclosure key to these AR goggles proved difficult to mold, 3D printing allowed the inventors to keep the complexity — while also making improvements for assembly and user experience.

Read MoreNew Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

Read More

.jpg;width=70;height=70;mode=crop)