When brothers Henry and David Pease began developing their Rekkie augmented reality goggles for downhill skiers, the two assumed that the enclosure for the necessary electronics would eventually be injection molded. But when the design proved to be expensive to create through molding, the Peases took a serious look at 3D printing. They partnered with Designfusion, a 3D printing brokerage, to continue to finesse the design and move into production with Multi Jet Fusion (MJF). The product, now for sale, reflects nuances of assembly, aesthetics and user experience that would not have been possible without additive manufacturing. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- More on Rekkie and its Smart Snow Goggles

- Design Fusion, Rekkie’s production partner

- Why 3D printing and inventors go together

- How Multi Jet Fusion works

- A different type of eyewear — in this case, customized glasses — featured on The Cool Parts Show

- Other examples of sporting equipment on The Cool Parts Show: helmet for martial arts, golf putter

Transcript

Pete Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Pete Zelinski

We are 4.2 miles apart.

Stephanie Hendrixson

But we can see each other's location through these goggles.

Pete Zelinski

Augmented reality ski goggles on this episode of The Cool Parts Show.

The Cool Parts Show is brought to you by Carpenter Additive. When it comes to managing metal powder, there is no one size fits all approach. Stick around after the episode to learn more.

Welcome to The Cool Parts Show.

Stephanie Hendrixson

This is our show all about cool, unique, innovative 3D printed parts. But contrary to what it may look like, this is not going to be our first episode in the metaverse.

Pete Zelinski

True, we are going to talk about augmented reality. These are augmented reality ski goggles made possible by additive manufacturing.

Stephanie Hendrixson

That's right. So these smart ski goggles were developed by a company called Rekkie. It was founded by two brothers, Henry and David Pease. They're both avid skiers, but they were frustrated with the issues around communicating while you are out skiing on the slopes. And so these augmented reality goggles are an answer to that.

00:01:04

Pete Zelinski

Right. So that experience, that challenge on the ski slopes, it led to an invention. As we've seen with inventors, 3D printing plays a role in product development. And then 3D printing can be the answer for production as well. So, Stephanie, where should we start?

Stephanie Hendrixson

Well, since neither one of us skis, I think maybe we should start with one of the inventors of this product. So here is Henry Pease kind of telling the story of where the idea for these goggles came from.

00:01:33

Henry Pease

I was skiing by myself, ridding up a chairlift at the end of the day, and I had a question in my mind as I got to the chairlift whether or not I would have enough time, if I really booked it to the bottom, to take another lift up and get one more run in. Or was the lift about to close anyway and was I better off just taking my time and enjoying this last run? And I just thought, isn't it so silly that I can't just have something basic to show me what time it is? I've tried on the Microsoft HoloLens, I've tried on like a bunch of other VR and AR goggles that are these really high-end, really immersive experiences. And I don't need that. I just need to have some basic information at this time. So I thought, wouldn't it be cool to build the thing that I want?

00:02:25

Pete Zelinski

All right. So skiing and another problem that came out as we were talking to Henry about this a little bit more. One of the challenges you're out skiing with friends and you lose track of them, you lose sight of them. So one of the really neat elements of the augmented reality display with these goggles is the way it gives you a bead on the precise locations of everybody who's in your ski party.

00:02:48

Stephanie Hendrixson

That's right. So the displays inside the goggles have some really useful things for the individual skier. Like a clock, like a compass. But they're really intended to be used in a group. So the goggles pair to your smartphone through the Rekkie app and then you can add other people to your group, whether they have their own pair of goggles or they just have the app. And then you can keep track of where everybody is.

00:03:09

Pete Zelinski

And that functionality led to 3D printing because Rekkie, these inventors, they didn't want the users to have to have this big, bulky electronics box on the side of the helmet. They devised a sleeker, more streamlined, more compact form to contain the electronics. And that resulted in some very complex components for the enclosure.

00:03:34

Stephanie Hendrixson

Right. So this enclosure is how we get to 3D printing. So from what I understand, Henry made some early prototypes that involved a lot of duct tape and off the shelf elements. But they got to the point where in order to really test this idea, they needed some sort of custom enclosure that was going to protect the electronics from the elements. And so Rekkie ended up getting a desktop 3D printer basically for the purpose of prototyping this box.

00:03:57

Henry Pease

This was just a cheap desktop PLA printer because I didn't really care about the durability of the part. At this point I just wanted to get something that would work and that would just show the proof of the concept of the idea.

In early product development, it was mostly off-the-shelf microcontrollers and boards that I was hand soldering together and then using a mixture of different ski goggles that I would buy and custom 3D printed components to interface with those goggles. We started to realize that this could be a real product that isn't just something hacked together, but this is something that we want to use every day.

00:04:39

Pete Zelinski

So they were 3D printing from the beginning. They just didn't realize that 3D printing also could provide an answer for production. Initially, they were thinking injection molding.

00:04:49

Henry Pease

Of course, we thought, let's, let's do the injection molding. We kind of had a design that we liked, but still making a lot of changes and tweaks as we, as we put it all together. But we also wanted to get the ball rolling with our manufacturing. So we had to send in our current version and get quotes for an injection mold of these plastic components.

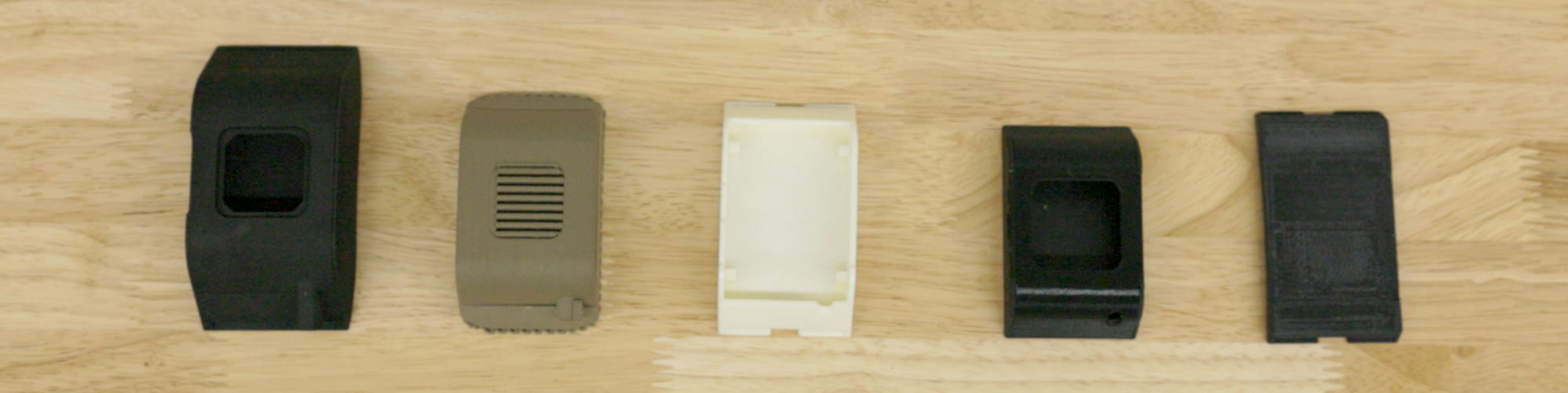

We did that and half the places said we can't make that. And the other half said, this is going to be really expensive. We loved spending the time to build a shape that the curves meshed around the helmet. On the inside of it - The parts that you can't see when you're wearing it on the inside of it, it's structurally built that every single component has its own little shelf and area where it nests in to make this thing really solid.

So as a result, it's really complicated and we had the freedom to do all of this when we were 3D printing it. Then we got to the point where we needed to injection mold it, and it's basically go back to putting just a big square box on the side of the strap. And at that point, I didn't realize how professional a 3D printed part could look.

It could look production quality.

00:06:05

Pete Zelinski

So this enclosure is not a box. It is this sleek form. And in fact, it has features on the inside that hold the electronics very well, like this shelf and this lip that kind of holds the board in place. But details like this add features and complexity to the injection mold resulting in expensive injection mold tooling.

00:06:31

Stephanie Hendrixson

The other issue was that if they invested in a mold tool, they were going to have to just commit to the design and they weren't quite ready to do that. But fortunately, they connected with this other company called Designfusion, which is a 3D printing brokerage.

00:06:45

Pete Zelinski

Designfusion, supplier of additive manufacturing systems and a broker for additive manufacturing capacity, helping fledgling manufacturers like Rekkie start to ramp up their production and get to the point where they can justify their own capacity, their own equipment.

00:07:03

Stephanie Hendrixson

And one of the things that design fusion does is they offer Multi Jet Fusion services. And so it turned out that these components that were developed with FDM that were going to be difficult to injection mold were actually a pretty good fit for the MJF process as well.

00:07:17

Trevor Johnstone

So companies that are looking to get into manufacturing for the first time, there's no tooling, right? So the beauty of an HP machine is you're prototyping on the exact same machine you're going to produce on. So your prototypes have way more information imbued in it, because you're going to go and take that into the field. Instead of having something that's close but not perfect, you take it out in the field and all that information you get back. What breaks? It's breaking on what you're going to eventually produce on. So the best thing about additive manufacturing is you're not paying for tooling. You're not frontloading your cost to find out later that the part doesn't work or there are edits required. Even though we're still beating it for low volume cost per part, more importantly, you're only spending the money on that part of the cycle as it's required.

You're not frontloading your risk. So especially if you're just starting a product and you don't know how much you're going to need, there's no cost to over buying because we deliver on demand and under buying with the speed we're at, you're talking a week turnaround time. So you're not like ordering it from overseas and if you've under-guessed the market, you're waiting months for your product to show up.

00:08:16

Stephanie Hendrixson

So Henry and David had had a lot of design freedom just using that desktop printer to to prototype this enclosure. But teaming up with Designfusion just sort of kicked things into high gear. Like within a few days they have a new MJF prototype in hand and then that collaboration, it all just snowballed and they went through lots of different design iterations to arrive at the product and the enclosure that we have here today.

00:08:37

Henry Pease

We also realized we didn't have to freeze our design process at that point. We were able to continue to test prototypes, decide we want something a little bit different. You know, this curve needs to just slope in a little bit more and that was no problem. We got, we got another small batch and we see how it comes together.

Not only was it really useful being able to make those little tweaks and modifications towards the end of the prototyping process. When it came time to actually set up an assembly line, we realized that there's a whole other set of little changes that we could make, usually to the internals of the components that would make it ten times easier to put it together and would result in a more consistent, high quality, durable product.

00:09:33

Pete Zelinski

Assembly was a consideration, too. Rekkie, they're manufacturers now, and they didn't want to rely too much on fasteners or on glue to put the product together. So they continued to iterate the plastic housing parts, adding features that aide during assembly. Basically snap fit the features so that the housing can go together and hold together. Snap together based on details that are 3D printed into the forms of the parts themselves.

00:10:04

Stephanie Hendrixson

Yeah. So 3D printing with MJF was kind of at first the solution to that mold problem, to not wanting to invest money into this mold and make compromises about the design. But Rekkie has been able to realize all these other benefits by using this as the production method. So making assembly easier, avoiding the fasteners, avoiding glue and stuff like that. And they've also been able to keep making changes, to keep improving on this design. They're not locked in because they don't have that hard tooling.

00:10:29

Shelby Daniels

We're packing 40 full cases in a build. We're doing one of those every 20 hours, and that's just on one machine. We're looking right at about 40 sets per build, and that's 10 hours to print, 10 hours to cool. But as soon as one is done printing, we put the next print in the build. So we kind of get an elegant dance going on of print, to cool, to print, to cool. After the parts cool, they go directly to a glass beads set up. But we're actually using an AMT Post Pro DP machine now, which bead blasts them for 60 minutes now, so they get bead blasted for a full 60 minutes. This not only removes the powder that exists on the outside of the raw parts, but we found at 60 minutes it starts to kind of smooth the outside surface of the parts a little bit, giving them more of a texture that Rekkie wanted on their goggles.

And after they are bead blasted, they go directly to dye where we dye all of their parts black. And that's all done in-house. After that, they go through a short dry session just to dry off from their rinse after the dye and they get bagged and then they are ready to ship to Rekkie for assembly.

00:11:44

Pete Zelinski

So that's how they're in production now. Mass production through Multi Jet Fusion. These goggles have gone to market. They are going to the ski slopes.

00:11:54

Stephanie Hendrixson

Yeah. And it's possible that the volumes could reach the point that at some point they'd have to reconsider that injection molding question. But Rekkie and Designfusion don't see that happening any time soon. Instead, they are focused on producing these goggles, continuing to improve this product, and also exploring other applications for augmented reality goggles. Whether that's other sports, whether it's search and rescue, any situation where you might already be wearing goggles, but want some additional information.

00:12:20

Pete Zelinski

All right. Rekkie augmented reality, ski goggles. So the inventors had this idea that while you're skiing, while you're wearing goggles, that could be a platform for projecting all this other information that would be useful to a skier. How fast you're going, for example, but also significantly the precise locations of everybody you're skiing with. Adding that functionality to goggles meant adding electronics.

That meant adding an electronics housing that needed to be compact. Getting to that resulted in some complex plastic parts which resulted in expensive mold tooling. So the company turned to 3D printing for production instead.

00:13:04

Stephanie Hendrixson

That's right. So these enclosure components were prototyped using FDM. The founders of Rekkie didn't want to commit completely to the design, didn't want to make the investment in that expensive mold tooling. Fortunately, they teamed up with a company called Designfusion, which offers Multi Jet Fusion services. And these components that would have been difficult to mold turned out to be a good fit for that technology.

So together they were able to keep iterating, keep improving this product. The enclosure that we have here today is assembled without fasteners or glue. It's all snap fit together. And these goggles are currently for sale. They're currently in the marketplace. Rekkie is going to continue to try to improve this product as well as apply this augmented reality goggle idea to other applications.

00:13:49

Pete Zelinski

All right, I think that'll do it. Thank you for watching. If you like the show, leave us a comment. Subscribe. I want to say thank you to friend of the show, Mark Lawry. He is the viewer who first told us about Rekkie.

Stephanie Hendrixson

Yeah, thank you, Mark. And if you have or know of a 3D printed part you'd like us to consider, please email us CoolParts@AdditiveManufacturing.media. Thanks for watching.

00:14:11

Pete Zelinski

This episode is brought to you by Carpenter Additive. We're past the point of not knowing how to qualify metal 3D printed parts. We know, it's just that different end users of those parts have different qualification requirements. Additive manufacturing service providers have to navigate that and Carpenter Additive has to think about that in tailoring powder management solutions.

00:14:35

William Herbert

Our customers typically will have - if they are a service provider, they will have a series of end user customers who may be OEMs in the aerospace world. And each of them has a fairly large team of engineers who have been doing this for decades or more and have developed all these standards, regulations, paperwork. So it is certainly a challenge to thread the needle between all of these different requirements.

We start really high level. We walk on the shop floor, we ask them about their source to sink, how do you bring in the materials, goods in, and send that material to each of the systems. And then what we're really interested in is how do they re-use that material? So what we do is called a value stream map. Pretty often that leads to a series of things that were either overlooked or hadn't really boiled up to the surface yet in terms of things that are potential risks or potential challenges or inefficiencies that exist.

A lot of the customers we work with, especially in the more regulated industries such as space or medical or aerospace, have already been through those early learning stages. They've put five plus years into this, they've done the product design and the design for additive manufacturing, and now they're starting to reach some of the more finicky problems that you get when you're at the scale of maybe five, ten machines.

You're running different materials simultaneously, you're doing different programs. We get to take the best from the medical field and the aerospace field. We understand the specifications and the standards that exist in each of those fields, and we can sort of take the best elements of those and customize that to our customers.

Related Content

EOS Launches Digital Foam Architects Network

EOS created the collaborative additive manufacturing alliance to accelerate time-to-market for 3D printed foam applications.

Read MoreMaterialise’s Translucent Material Expands Eyewear Design Capabilities

The company opens up new design possibilities with the fusion of 3D printing and translucent material.

Read MoreHP Works With Brooks Running to 3D Print Performance Footwear

HP has collaborated with Brooks Running to create the Brooks Exhilarate-BL which features 3DNA, a 3D-printed midsole technology that delivers a propulsive, bouncy ride.

Read More3DEO Wins Design Excellence Awards

3DEO was recognized for outstanding applications of powder metallurgy.

Read MoreRead Next

Additive Manufacturing Creates New Paths to Production

On the journey from product idea to production, when does the “mold moment” come? That is, the moment of needing to invest in tooling and make design commitments. 3D printing can delay this step on the journey or even avoid it altogether.

Read MoreFitz Frames Brings Mass Customization to Eyewear with Affordable 3D Printed Glasses Frames

Glasses don’t need to be ill-fitting and frustrating to buy. Fitz Frames offers a different kind of shopping experience (using augmented reality and 3D measurement) to produce custom glasses with 3D printed frames that are affordable, durable, comfortable and stylish.

Read MoreWhy Inventors and Additive Manufacturing Go Together: AM Radio #13

The ease of beginning to produce at small scales using 3D printing opens the way to a new class of manufacturer: the inventor making their own product.

Read More

.jpg;width=70;height=70;mode=crop)