Where is additive manufacturing (the technology) at the end of 2022? It’s hard to draw big conclusions about AM as a whole, but looking at the top stories Additive Manufacturing Media has posted this year offers a couple of potential insights about where this method of production is and where it is heading. I recently discussed our top 10 stories of 2022 on the AM Radio podcast along with Peter Zelinski and Jodee McElfresh (listen above or scroll down for the countdown of our most-viewed pieces from the past year).

3D printing as a means for obtaining replacement parts, for example, comes up in at least four of these stories albeit in very different ways. Printed spare parts are beginning to be a more common choice, and we are developing the systems and methodologies needed to ensure their success. Trends toward electrification are evident here as well with two different videos below, one focused on a 3D printed cutting tool for machining EV engine bores, and the other about directly 3D printing rotors for electric motors. Meanwhile, additive manufacturing is maturing as a business model, as evidenced by coverage of companies that are reshaping factories and have grown into production.

And this isn’t a trend exactly, but it’s worth noting that two episodes featuring winners of The Cool Parts Showcase contest made the list; these viewer-elected parts are cool to look at, but also have something to say about materials, design and applications for AM going forward. (Bonus meta-trend: Fully half of this year’s list is video content. Our text articles are still incredibly important vehicles for conveying ideas about AM, but the value of audio/visual examples cannot be denied.)

Here are our top 10 stories from 2022, starting with number 10:

10. 500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

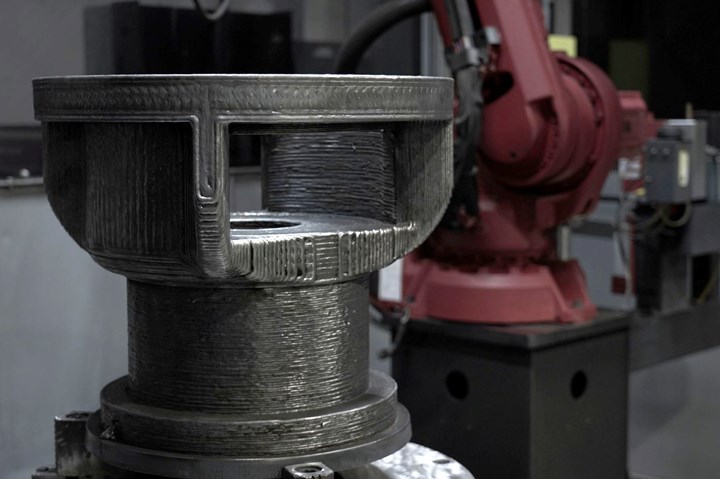

Lincoln Electric Additive Solutions 3D printed this 500-pound bearing housing using wire arc additive manufacturing (WAAM). The component is a replacement for a piece of equipment used by its parent company to manufacture flux used on stick electrodes for welding.

This episode of The Cool Parts Show highlights a carbon steel bearing housing for a nearly 100-year-old machine used for mixing flux for welding electrodes. The carbon steel component was printed through WAAM and incorporates design improvements that will carry through to other replacement parts.

Key takeaways: No drawings, files or tooling existed for this housing, which was recreated by Lincoln Electric’s AM group for its welding division. Without WAAM, the path for replacement might have been much more complicated. (Bonus: While filming this episode on-site, we learned about a new WAAM application Lincoln Electric discovered on the same piece of equipment, this time the mixer blade.)

9. Can Metal Parts Be Replaced With 3D Printed Composites?

Werco Manufacturing is answering that question with its use of reinforced 3D printed polymers as an alternative to salvaged parts for aircraft training devices. Using materials like carbon PEEK, the company is able to print, machine and even powder coat components that are used by the next generation of aircraft technicians.

Key takeaways: While these 3D printed parts won’t take to the skies anytime soon, they still need to meet many of the same requirements as the original aircraft components. Proving 3D printed composites in aircraft trainers on the ground could help clear the way for printing more direct replacement or new parts in the future.

8. How Siemens Energy Applies Additive Manufacturing for Power Generation and More

Siemens Energy’s Orlando-based additive manufacturing center is meeting a unique set of challenges, serving internal energy customers as well as external ones, and pursuing both emergency “push” applications for additive alongside longer-term “pull” ones.

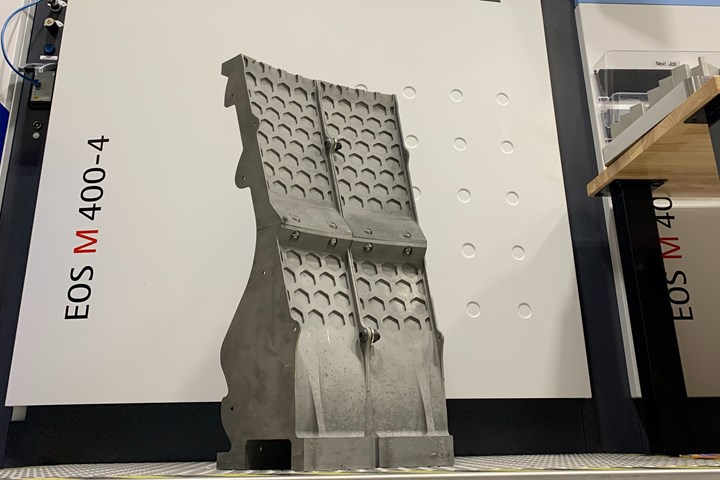

These components 3D printed on the EOS machine in the background are part of a large ring for a generator cover, which replaces a bronze casting with a long lead time. The application is an example of a “push” opportunity, where AM was able to step in and reduce both the weight and procurement time. Photo Credit: Siemens Energy

Key takeaways: Siemens is proving that additive has a valuable role to play when replacement parts are needed fast, but focusing only on spares is short-sighted. The dual push-and-pull strategy allows for better use of additive over the long term.

7. 3D Printing Rotors for Electric Motors (Video)

In this video, a researcher at Oak Ridge National Laboratory’s Manufacturing Demonstration Facility discusses her work in producing rotors for electric motors with laser powder bed fusion.

Key takeaways: Rotors are typically made through winding and the ductility required for manufacturing means trade-offs in operation. 3D printing removes the need for ductility, allowing for increased silicon content and better performance.

6. Custom Canine Wheelchair From Carbon Fiber-Reinforced PP: The Cool Parts Show #44

Wobbly Hannah, a dog with a mobility condition called cerebellar hypoplasia, uses assistive devices to move freely and safely. The wheelchair shown here was created by Dive Design using Braskem’s carbon fiber-reinforced polypropylene filament. Photo Credit: Braskem; Dive Design

This episode of The Cool Parts Show highlights the 2021 winner of the Best Bespoke Solution category for The Cool Parts Showcase contest. Engineering firm Dive Design and materials company Braskem combined forces to create a custom mobility device for Wobbly Hannah, a dog with cerebellar hypoplasia.

Key takeaways: Creating a custom device for a pet is challenging under the best of circumstances, more so when the bulk of the work takes place remotely. Hannah’s wheelchair is also one of the earliest applications for Braskem’s carbon fiber-reinforced polypropylene, a high-performance material that brought the necessary strength and durability for this device.

5. The First Choice Was Right: How RP+M Succeeded With Production FDM

In this article, we revisit the subject of the very first cover story of Additive Manufacturing magazine. In 2012, Thogus Products Company was dabbling in AM for prototyping, tooling and production. Today, RP+M, the additive manufacturing spinoff Thogus launched soon after our first article, has thoroughly established itself as a production-scale aerospace provider leaning hard into one particular format of 3D printing: FDM.

Key takeaways: RP+M’s work to characterize and control the FDM process has been critical to its production success, as well as the development of an aerospace industry specification. This formula for production coupled with its business strategy have helped the company win work from major customers including Boeing and Lockheed Martin.

4. For Polymer 3D Printers, Metal Parts Are Now Within Reach

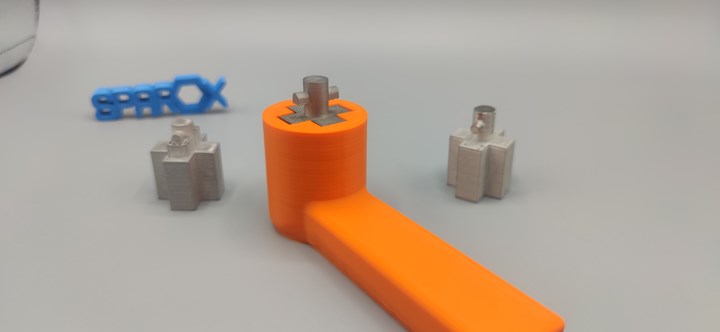

With the launch of BASF Forward AM’s line of Ultrafuse filaments that carry metal powder mixed with thermoplastic binders, users of extrusion 3D printers meant for polymers can now produce their own green metal parts in house. This story explores how and why Sparox 3D, a spinout from Wien Energy in Austria, opted to utilize its existing fleet of Ultimaker 3D printers with hardware and software upgrades to print in metal, rather than outsourcing metal parts or adopting a different metal-focused system.

With just small hardware and software upgrades, users of affordable desktop 3D printers for polymers can now 3D print green metal parts that can be sintered to final density. Shown here is a tool Sparox created to open windows at Wien Energy, which combines a metal insert made with BASF’s Ultrafuse filament on Ultimaker printers, with a polymer handle printed on the same machine. Photo Credit: Sparox.eu

Key takeaways: Metal fused filament fabrication (MFFF) offers a way for users of affordable desktop-style polymer printers to bring metal 3D printing all or mostly in-house. Users retain their IP and control over their green parts, but can leverage BASF’s sintering partner services to obtain reliable dense metal parts without having to add this capability.

3. 10 Ways Additive Manufacturing Reshapes a Production Facility (Forget What You Know About Factories)

Sintavia’s purpose-built facility for powder bed fusion of aircraft components looks, sounds and even feels different from the stereotypical factory we might imagine. Additive manufacturing production is quiet; more autonomous; and produces less waste than conventional manufacturing processes. 10 key differences in this article.

Key takeaways: The physical aspects of Sintavia’s facility are really just the manifestation of what the company has achieved in terms of its process for high-end part production. Each aspect of the building serves AM production.

2. 3D Printed Tool for Machining Electric Vehicle Motors: The Cool Parts Show #39

This large tool actually performs three different operations in one pass, simplifying the cutting of stator bores for EV engines.

This episode of The Cool Parts Show features a lightweight boring tool developed by Kennametal for cutting the stator bore of an electric vehicle (EV) motor. We look at both a full metal version of the tool as well as one that incorporates a carbon fiber composite shaft for even greater weight savings.

Key takeaways: Producing this cutting tool conventionally would have resulted in a boring tool that was too heavy for use in the machining centers and toolchangers designated for this work. AM brings lightweighting, through-tool coolant and additional benefits. And, while the two processes compete in some ways, the next advances in machining could be aided by AM.

1. 3D Printed Heat Exchanger Uses Gyroids for Better Cooling | The Cool Parts Show #43

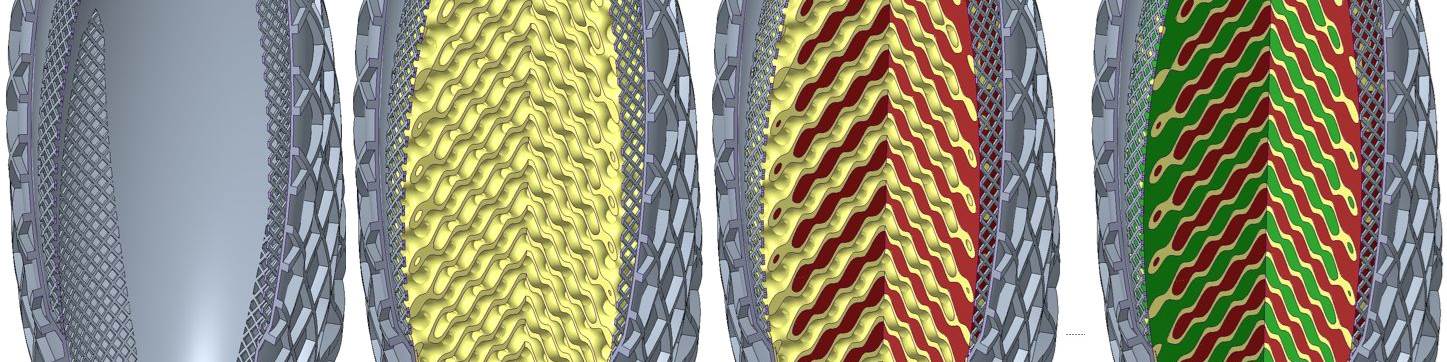

This 3D printed heat exchanger is filled with gyroids inside to facilitate efficient cooling of the helicopter’s gearbox oil using the aircraft’s own fuel as the cooling liquid. Photo Credit: Advanced Engineering Solutions

Our top story from 2022 is the winner of The Cool Parts Showcase in the Best Proof-of-Concept category. Advanced Engineering Solutions developed this heat exchanger for a helicopter that incorporates design features inspired by nature: gyroids, which increase the surface area inside the heat exchanger and allow for more efficient thermal transfer.

Key takeaways: Additive manufacturing is allowing for the physical production of biomimicry-inspired features and complex designs that previously could not have been produced. Heat exchangers are just one of the possible beneficiaries.

Related Content

Why AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreRead Next

How Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MoreCan Metal Parts Be Replaced With 3D Printed Composites?

High performance materials such as carbon PEEK have allowed Werco Manufacturing to 3D print parts for aircraft trainers that function like metal. But can this extend to end-use aircraft parts?

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read More

.jpg;width=70;height=70;mode=crop)