Laser Powder Bed Fusion

Materialise and Renishaw Integrate Systems to Improve Efficiency of Metal 3D Printing

Renishaw system users can now benefit from Materialise’s build processor software as well as its Magics data and build preparation software.

Angela Osborne

Managing Editor, Gardner Business Media

EOS M 290 1kW Metal AM System Engineered for Materials, Applications That Demand Higher Intensity

The EOS M 290 1kW metal printer features a one-kilowatt laser with the flexible, midsize frame to deliver the power needed to maximize production of industrial applications for copper and copper alloy, with more materials coming.

Read MoreAdditive Plus to Distribute Farsoon Technology on West Coast

With an open system providing full laser control, Farsoon’s technology offers the freedom to work with any material and control all printing parameters.

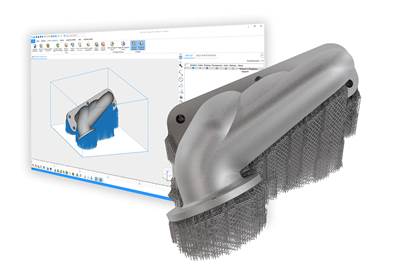

Read MoreMaterialise Software Module Optimizes Data and Build Preparation for Metal LPBF

The e-Stage for Metal+ software uses physics-based modeling to improve automated support structure generation for laser powder bed fusion.

Read MoreVariable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

Read MoreNick Estock Appointed Deputy CEO for AddUp North America.

Estock has more than 15 years of experience in the manufacturing industry, with a background in design, product development and new product introduction.

Read MoreNovastar Solutions Named Farsoon Distribution Partner

Novastar now distributes Farsoon’s open, industrial-grade metal and plastic 3D printing machines to customers in Michigan, Ohio and Indiana.

Read MoreVideo: Ergonomics and Economics of Really Big Laser Powder Bed Fusion

The DMP Factory 500 solution currently operating at CIMP-3D offers a look at the equipment and steps necessary to 3D print metal parts at large scale.

Stephanie Hendrixson

Executive Editor, Additive Manufacturing

AddUp and Anatomic Implants Collaborate on FDA Submission for 3D Printed Toe Joint Replacement

Anatomic Implants has chosen to use AddUp’s FormUp 350 Powder Bed Fusion machine to qualify the implant for submission to the FDA. The FormUp 350 is able to produce varying complex geometries with fine detailed lattice structures, which are well suited for implantable medical devices.

Read MoreCRP Technology’s Windform SL Is Lightweight, Rigid Composite for SLS, LPBF

Windform SL is well suited for the the production of sophisticated, efficient components across various fields, from aerospace to automotive, ensuring light weight without the need to reduce thickness.

Read MoreAconity3D, Equispheres Achieve Productivity Gains for Metal 3D Printing

The companies say they have achieved remarkable productivity improvements using laser beam shaping and NExP-1 high-performance AM powder.

Read MoreMPI Launches AI Project to Create Material Reuse Management Tool for Metal 3D Printing

MPI is working with Additive Manufacturing Solutions and AMFG to create a versatile, commercial predictive material reuse management tool that will enable additive manufacturing to expand by introducing greater cost efficiencies.

Read MoreAddUp, SSG to Introduce Tool Steel Optimized for Injection Molding Applications in Additive Manufacturing

SSG developed the Printdur HCT material to meet the requirements of injection molding, enabling manufacturers to significantly reduce production cycles using conformal cooling channels.

Read MoreMT Aerospace Expands Services With AddUp PBF Technology

MT Aerospace says its FormUp 350 machines have proven their ability to produce highly complex parts, such as heat exchangers, with an unrivalled surface finish.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

Zeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreThis 3D Printed Part Makes IndyCar Racing Safer: The Cool Parts Show #67

The top frame is a newer addition to Indycar vehicles, but one that has dramatically improved the safety of the sport. We look at the original component and its next generation in this episode of The Cool Parts Show.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreCi-Esse Joins Velo3D’s Contract Manufacturer Network in Italy

Italian contract manufacturer Ci-Esse acquires Velo3D sapphire printer to enhance its additive manufacturing capabilities with the fully integrated solution being used to support Ci-Esse’s aerospace, defense and motorsports customers by providing mission-critical metal parts.

Read MoreFarsoon Develops Ultra Temperature UT252P Plastic LPBF system

The UT252P is based on Farsoon’s 252P laser powder bed fusion system and was developed to offer an even higher chamber temperature capacity for processing materials with high melting points over 340°C.

Read MoreAmerica Makes Awards $3.2M for Delta Qual Project Winners

The project call winners are tasked with creating qualified additive manufacturing (AM) processes that offer rapid and affordable flexibility in crucial processes, postprocessing and material feedstock variables, while efficiently validating a qualified AM material through statistical analysis.

Read MoreSouthern Indiana’s Thriving AM Part Producer — What I Saw at Innovative 3D Manufacturing: AM Radio #49

Recorded just after the visit to the laser powder bed fusion contract manufacturer, here is a conversation exploring observations and impressions of this company and its metal 3D printing work.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreWhat We Found at Formnext 2023

New metal processes, new possibilities for existing processes, the next step for copper and more. Here is a summary drawing on all our reporting from November’s event.

Read MoreRenishaw RenAM 500Q Ultra AM System Features Productivity-Boosting Tempus Technology

The Tempus technology incorporates scanning algorithms that enable the laser to fire while the recoater is moving, saving up to nine seconds per build layer.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreFarsoon FS350M-4 Metal AM System Offers Optimal Build Efficiency, Uniform Part Performance

The system is equipped with an advanced multilaser scanning strategy and calibration algorithms which can enable optimal build efficiency and uniformed part performance throughout the build area.

Read MoreArcelorMittal Enters Additive Manufacturing Industry With Steel Powder

The company is building an industrial-scale atomizer in Spain to produce high-quality steel powders for multiple additive manufacturing technologies.

Read More