Replique Announces Public Launch of 3D Printing Material Hub

Following a successful beta release, the Material Hub is now openly accessible to the broader additive manufacturing community. It contains a collection of more than 400 polymer materials which have been compiled in collaboration with more than 25 material providers.

Share

Read Next

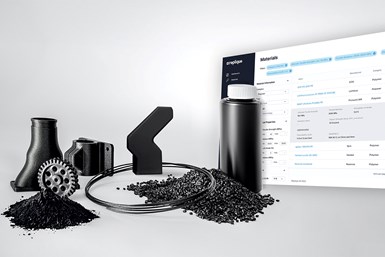

The Material Hub enables users to quickly find the right material according to their requirements. Source: Replique

Replique, provider of a decentralized 3D printing platform for the secure and reliable production of industrial-grade parts, has launched an extensive public Material Hub for 3D printing which is now open to the public following beta testing. After the successful beta release, which the company says received overwhelmingly positive feedback, Replique is now introducing the database to the broader additive manufacturing (AM) community.

The Material Hub is now openly accessible and contains a collection of more than 400 polymer materials, compiled in collaboration with more than 25 material providers. This marks a substantial increase, more than doubling the number of available materials since its initial introduction in November 2023.

Already in the beta phase, the hub helped numerous companies, institutions and partners to access and filter options for the right 3D printing materials in seconds.

“Replique’s Material Hub significantly accelerates the material selection process,” says Mathilde Lepilliez, Alstom innovation manager and 3D printing engineer. “Just recently, we have searched for a material that fulfills our high flame-retardancy requirements as part of a new 3D printing project. Thanks to Replique’s support we were able to find the right material fast and efficiently. This Material Hub will become a part of our daily-basis tools to help us to develop 3D printing.”

Replique says the Material Hub offers a variety of benefits and features to engineers, purchasers and R&D. Users can easily navigate the hub because of the technical filtering options to find the ideal materials for their specific applications, saving time and costs associated with manual research. Detailed technical specifications, industry standards and application fields are provided for each material, ensuring informed decision-making.

Additionally, printer manufacturers, service providers and other stakeholders can benefit from the collective knowledge within the database, fostering collaboration and innovation within the 3D printing community.

With the public launch, Replique has incorporated performance improvements based on user feedback, including an optimized search function. This enables users to either search on a detailed level, such as direction-dependent mechanical properties or on a more beginner-friendly level. Thus, also enabling less-experienced users to use the tool efficiently and get a head start on their adoption of AM. Once a suitable material is identified, users can also directly request a quote to get their parts produced through Replique or reach out to the material provider to clarify further details.

“We are thrilled with the positive reception of our Material Hub during the beta phase,” says Dr. Max Siebert, Replique co-founder and CEO. “The public launch marks an important step in our mission to democratize access to additive manufacturing. We are committed to continuously enhancing the platform to meet the evolving needs of our users.”

In the future, Replique plans on expanding the hub’s capabilities by adding more features and materials. While the current focus is on polymers, adding metal materials is already planned. Material providers interested in showcasing their materials are encouraged to reach out to Replique directly.

Related Content

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreDrones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)