BCN3D Spins Off VLM Business Unit, Creates Supernova 3D Company

The new company’s focus will be on materials development targeting industrial applications, as well as the industrialization of the product ecosystem, with the first beta systems to be installed in 2024.

BCN3D recently spun off its Viscous Lithography Manufacturing (VLM) business unit into Supernova, an independent company that has been incorporated in the U.S. and will have headquarters in both Austin, Texas, and Barcelona, Spain. Supernova is not a subsidiary of BCN3D. Instead, the two entities are completely independent.

Supernova’s aim is to unlock production applications by combining high-performance materials, a scalable production platform, and competitive cost per part, based on its patented Viscous Lithography Manufacturing (VLM) technology and proprietary high-viscosity materials. The company says it unlocks real production applications by providing solutions that combine quality, productivity and a competitive cost.

The company’s focus in the next year will be on materials development targeting industrial applications, as well as the industrialization of the product ecosystem, with the first beta systems to be installed in 2024. Supernova begins with significant market traction, with more than 500 companies registering in the Technology Adoption Program, as well as key partnerships with customers in the industry such as Puma, Saint Gobain, Orbea, Hutchison or Prodrive.

BCN3D’s purpose is to enable innovators to create the future by making industrial additive manufacturing (AM) accessible. The company focuses on enabling engineers to enhance product design through functional prototyping and to improve factory operations with tooling, jigs and fixtures.

To be successful, each of those visions will require a distinct business model, company structure and, most importantly, a laser-focused team. The technologies, customers, applications and materials all differ significantly. By carving out its VLM business unit into Supernova, BCN3D ensures that each has its own space to flourish in the long term.

Supernova will be led by Roger Antunez as CEO, who previously served as the general manager of BCN3D since 2019. Joining him as a co-founder is Marta Mico, formerly the VLM head of business development at BCN3D. Additionally, Eric Pallares, the former CTO of BCN3D, will join Supernova as a distinguished technologist. Meanwhile, the rest of the team will remain at BCN3D, with Pol Domenech, the sales director, stepping up as the new general manager.

Under the leadership of its CEO, Xavi M. Faneca, BCN3D will continue to focus on its core business of extrusion-based technologies. The company aims to expand its leadership in the IDEX segment and grow its industrial offering with products like the Omega I60, an all-in-one industrial FFF 3D printer built for the factory floor featuring IDEX technology, an actively heated printing chamber, a large print volume and an architecture ready for high speed.

At the core of Supernova is VLM, a lithography-based AM process that laminates thin layers of high-viscosity resins onto a transparent transfer film prior to photopolymerizing the resin into the 3D printed object. The company says the resins can be up to 100 times more viscous than those used in traditional DLP, SLA or MSLA processes, unlocking a range of properties. These properties are closer to thermoplastics than standard thermosets, achieved in an efficient and scalable manner.

With the formulation freedom enabled by high viscosity, Supernova’s materials portfolio benefits from a broader set of available ingredients for achieving superior properties. From a chemical-base standpoint, the process can handle not only acrylates but also silicones, epoxies or filled materials, among others. To support its long-term materials strategy, Supernova has formed partnerships with major chemical companies in AM. These relationships include a joint development agreement (JDA) with Arkema and other partnerships with Altana, Elkem, Henkel and Rahn.

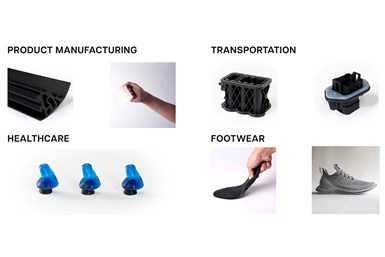

VLM technology has garnered significant interest in the market, evidenced by the registration of over 500 companies in the Technology Adoption Program. These companies span various industries, including automotive, aerospace, manufacturing, consumer goods, footwear, audiology and health care, among others. Strategic partnerships with customers have been driving the materials and technology development in alignment with customer needs. Apart from industrial markets, Supernova will also concentrate on the defense and space sectors, aiming to develop industry-specific materials that other existing AM technologies cannot process.

During the next year, Supernova plans to leverage the Technology Adoption Program to develop applications in key vertical markets. This initiative aims to influence both materials development and the industrialization of hardware systems, ultimately forming a production-ready ecosystem. Beta deployments in customer sites are expected during 2024. In line with these goals, the company will be expanding its R&D teams in both materials and product (or hardware and software), as well as its business departments.

Related Content

Solving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More