For some companies that adopt additive manufacturing (AM), the trajectory of that adoption is toward scale production. Success with one or a few 3D printers means adding more machines, pursuing more part numbers, and leaning in to increasing quantities. If 3D printing is suitable for production, the thinking goes, then it should do what other production technologies do: Scale up, and increase output.

AM’s trajectory has been different at Resolution Medical. Here, 3D printing is not the way to make hundreds of thousands of parts, nor does the company aspire to this. AM is instead the way to make some parts, maybe even quite a few parts — until, at some point, maybe it isn’t the way anymore. The goal is not for additive to “win” or to reach greater and greater quantities. Instead, the goal is for each medical device, or other product Resolution works to develop, to get to commercialization quickly.

If demand is low enough that the item can continue to be produced through 3D printing, then this is a success for additive. But should volumes exceed what 3D printing can deliver, this is a different kind of success for additive. AM in this scenario has served its purpose by bringing time and cost savings to the product’s development, supporting innovative design, and enabling rapid iteration. Even when production outgrows additive manufacturing, AM has been the launchpad to make that higher-volume production possible.

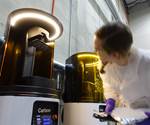

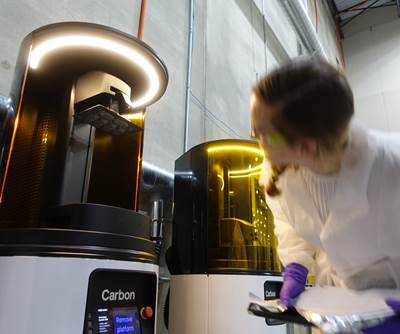

Since my last visit to Resolution Medical, the company has doubled its Carbon M2 fleet from three printers to six. The added printers are not meant for scaling up production of any individual product, but for serving more customers bringing ideas to market.

3D Printing Capability, Not Capacity

Located in Fridley, Minnesota, not far from Minneapolis, Resolution Medical develops and manufactures products for clients ranging from individual doctors to mid-sized medical device companies to a few larger OEMs. Since its launch in 2012, co-founders Shawn Patterson and Steven Schmidt have chosen to focus the company’s activities on these types of customers, the ones who might otherwise get overlooked by larger manufacturers. The company offers extensive product development services as well as injection molding, machining, composite winding, assembly and more to bring ideas into reality.

In addition to the new 3D printing equipment, Resolution Medical has also expanded in other ways like adding a second cleanroom.

I first visited Resolution Medical in late 2018, not long after the company had installed its first two digital light processing (DLP) 3D printers from Carbon; by the time my story appeared in 2019 there were three total Carbon M2s on site. The company had just 30 employees and plenty of open floor space in its 36,000-square-foot facility. At the time, it seemed that Resolution might follow that same trajectory that other AM adopters have taken: add 3D printing as another service offered, win work for these machines, and ramp up production through this capacity.

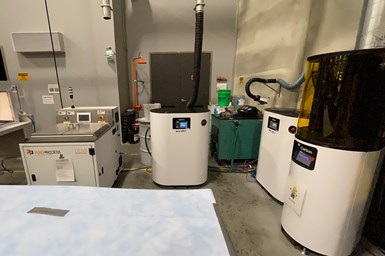

When I returned in February 2022, the production floor still had some of the same landmarks — an area devoted to injection molding, a brightly lit cleanroom, the 3D printers occupying one corner of the building — but there were many more pieces of equipment, more employees (about 160 these days) and more work in progress. Walls have come and gone. The cleanroom square footage has more than tripled with the addition of a second cleanroom now dedicated to R&D so that the original space can focus on production. Extrusion-style printers from Stratasys, Makerbot and FlashForge used for prototyping have sprung up in their own dedicated area. And the production 3D printing space has grown to include six Carbon M2 machines, plus two curing ovens, two Carbon parts washers and a third cleaning system from PostProcess Technologies.

In other words, Resolution was bursting at the seams — and had just secured space in the building across its parking lot that will allow it to spread out, expand and prepare for more growth yet to come. Engineering and R&D will move to this new space, allowing the original facility to focus on production.

But the fact that Resolution Medical has doubled its production 3D printing capacity does not mean it has also doubled production volumes. “This is capability, not capacity,” explains Drew Richardson, director of additive and component development. The Carbon machines are not devoted to making greater and greater quantities of parts in serial production; rather these half-dozen printers mean that Resolution can do more product development and keep up with the production that this activity entails.

When Prototyping Means Production

Most of Resolution Medical’s clients are companies and individuals aiming to introduce new medical devices to the market. Any new surgical device, active implantable device, catheter delivery system or other tool must go through FDA evaluation and often clinical testing, which means real, usable devices must be manufactured in the development stage. For injection molded components, this can be a significant challenge; it puts inventors and developers in the position of buying expensive mold tooling perhaps even before they are sure of the device’s final design. With its Carbon 3D printers and FDA-approved resins, Resolution offers a more flexible and affordable option for making these initial devices; clients can avoid being locked into the expense and timelines of traditional mold tooling while also having more freedom to make changes.

“You don’t have to put down $50,000 in mold tooling if the design isn’t set yet.”

“It’s a stroke of the keyboard and we’ve changed the design,” Richardson says. “You don’t have to put down $50,000 in mold tooling if the design isn’t set yet.”

When the design is finalized, or when it at least seems that it might be finalized, Resolution Medical can 3D print the parts needed for clinical trials, which might amount to hundreds or even thousands of devices — batches that look more like small-scale production than prototyping. In some cases 3D printing will continue to be the production method beyond this initial run because of the low quantities needed or some other aspect of the part. Loving Eyes is one example; this organization provides eyeglasses for children who cannot wear standard frames. Loving Eyes designs custom frames for each child which Resolution then 3D prints. The uniqueness of each set of frames means that this will always be an ongoing production job for the 3D printers.

Glasses frames from Loving Eyes are unique to each child; a mass customization application like this would be impractical to move to injection molding, and so DLP will remain the production technology.

But for many devices there will come a point where the volumes needed are high enough that injection molding for production will make greater economic sense. Resolution Medical uses forecasting tools and projections to help customers anticipate this pivot, so that production can move from 3D printing to molding as seamlessly as possible. This might mean, for example, designing a catheter handle in two parts, even though the complete item could be 3D printed as just one piece — because this choice will make it easier to translate the halves into two injection mold cavities later.

A prototype of a catheter handle made using the Carbon printers. It might be possible to 3D print the entire enclosure with the dial piece inside, but this is an example of a product that will likely go on to be injection molded — therefore designing the device in moldable halves made more sense.

The same catheter handle as assembled. Texture options built into the Carbon software make it possible to vary the surfaces of these 3D printed parts — and even imitate the finish that might be achieved through injection molding.

Resolution is facing this transition now with a device called the Hummingbird Tympanostomy Tube System (TTS) that was created by a doctor to place tubes in children’s ears, a treatment for fluid buildup behind the eardrum that can cause pain and hearing loss. Typically this procedure requires anesthesia and takes place in an operating room. The Hummingbird TTS device, however, would allow ENT surgeons to carry out the procedure in an office setting. The device consists of a plastic handle with a long metal tube that punctures the eardrum in order to place the tube and facilitate drainage. The version of the device pictured here will move to injection molding later this year, with just a few tweaks (like modifying the star grip pattern to move it away from the handle’s parting line). Injection molding will allow this device to be made in the high volumes that this common procedure dictates, but arriving at this nearly final design has already involved 3D printing thousands of functional parts — a prototyping application that looks quite a bit like production.

The Hummingbird TTS will ultimately be produced via injection molding, but DLP 3D printing was the right way to manufacture it in development for its time savings and flexibility. Photo Credit: Resolution Medical

Aiming for the “Hockey Stick”

The Hummingbird example is reflective of the type of product development Resolution Medical hopes to work on, where it can help inventors reach commercialization with their product.

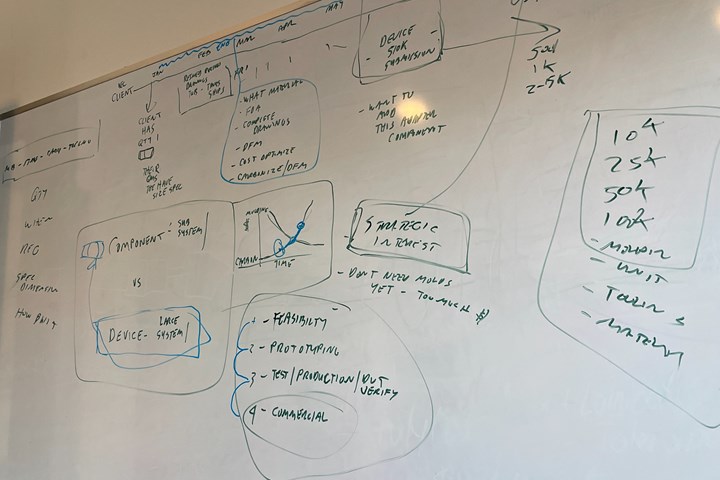

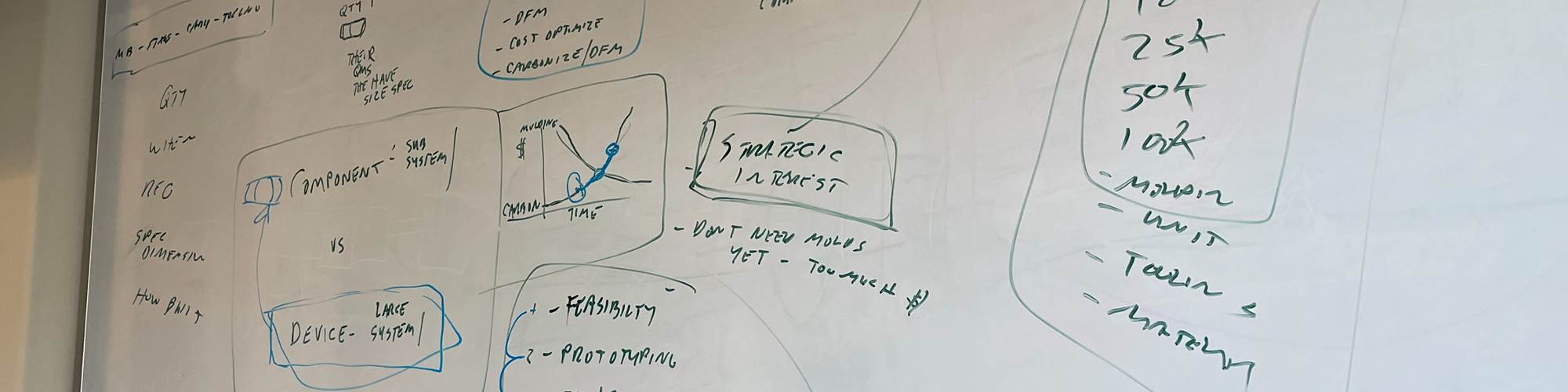

“We are after those ‘hockey stick’ applications,” says Jesse Carlson, vice president of business development, referring to products with a short ramp-up followed by rapid rise in quantities, resembling a hockey stick on a graph. In the company’s experience, only about one in every 10 applications will reach this level. That means Resolution needs a lot of irons in the fire to find them; at any given time, the company has more than 20 products in various stages of development, Carlson says.

Conversations with customers must get beyond the technical details and needs of the part. Frank discussions about projected sales and market size with clients help Resolution make the right choices in developing a product for commercialization, at any scale.

Thus far, the company has developed more than 10 product lines through commercialization. All have been finished medical devices, but this could change. Despite its name, Resolution Medical is actually interested in getting beyond the "medical" in its components business. It has already done some industrial product development and production including parts for the automotive industry. There is some intersection between automotive’s PPAP procedures and the FDA approval process that Resolution is familiar with; finding and understanding the overlaps will help the company expand into new industries.

Branching out from medical might not be the expected move, but then, neither is adding production 3D printers without the aim of chasing mass production through additive. The product development support that Resolution offers transcends industry, business size or product demand, and additive manufacturing is a valuable tool for launching even complex new products.

"If it's easy, people aren't going to come to us," Richardson says. "We are here to serve the great ideas where there's no other way to bring it to fruition."

Related Content

Ice 3D Printing of Sacrificial Structures as Small as Blood Vessels

Using water for sacrificial tooling, Carnegie Mellon researchers have created a microscale method for 3D printing intricate structures small enough to create vasculature in artificial tissue. The biomedical research potentially has implications for other microscale and microfluidics applications.

Read More8 Transformations 3D Printing Is Making Possible

Additive manufacturing changes every space it touches; progress can be tracked by looking for moments of transformation. Here are 8 places where 3D printing is enabling transformative change.

Read MoreTo Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreRead Next

Why Makelab Is Still Betting on 3D Printing for Product Development

Three years ago Christina Perla was an industrial designer using the services of a local 3D printing hub. Today she’s the co-owner of that company, and doubling down on its prototyping roots.

Read MoreInjection Mold or 3D Print? How Resolution Medical Pivots Production

Minnesota manufacturer Resolution Medical is finding opportunities for additive manufacturing via Carbon 3D printers as an alternative to injection molding for production.

Read MoreHow Bridge Production Is Bringing New Possibilities: AM Radio #14A

Additive manufacturing makes bridge production a more natural factor in the production strategy overall. This has important implications for product development and even what products are possible.

Read More

.jpg;width=70;height=70;mode=crop)