“I look at it as a roadmap,” says Greg Bartley, chief commercial officer of Continuum Powders. “We are already producing powder from recycled content, using low energy density and doing so efficiently. As a sustainable materials company we asked, what could be next?”

“We want to take all the steps within our control to make sure we’re being as sustainable as we can be,” says Greg Bartley, CCO of Continuum Powders. Source: Continuum Powders

The answer Bartley and the company came to was to reevaluate the energy powering its metal atomization process, to seek out more renewable energy sources. To that end, Continuum Powders just recently announced a new partnership with Priority Power, a broker that is helping the company secure renewable energy to power its compact material foundries, and Airgas, which supplies those foundries with argon that is produced with 99.8% renewable energy.

By seeking out renewable power and argon produced with renewable energy, Continuum Powders aims to reduce its total energy consumption and carbon footprint. The company says that the move also allows for decarbonization benefits to be passed onto customers.

AM Powders from Secondary-Use Materials

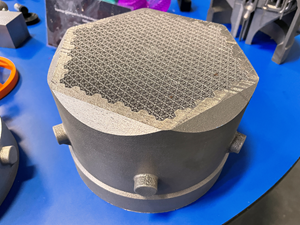

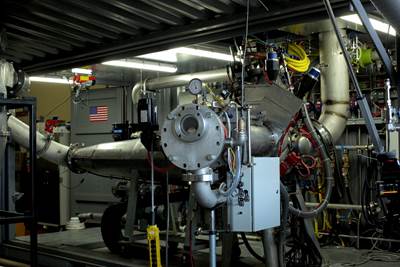

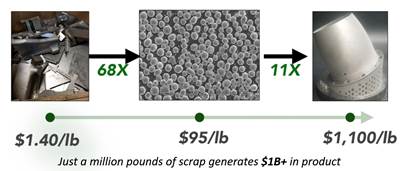

Continuum Powders is part of the latest evolution of MolyWorks, the California-based startup that developed a portable atomizer which can be operated within an enclosure the size of a shipping container. These “Greyhound” powder foundries are designed to recycle secondary-use materials (which could be anything from spent powder to support structures to failed builds to conventional ingot) into metal powders suitable for additive manufacturing in just one step. Feedstock material is melted with a plasma torch and passed through a stream of argon gas to become spherical powders ready for 3D printing.

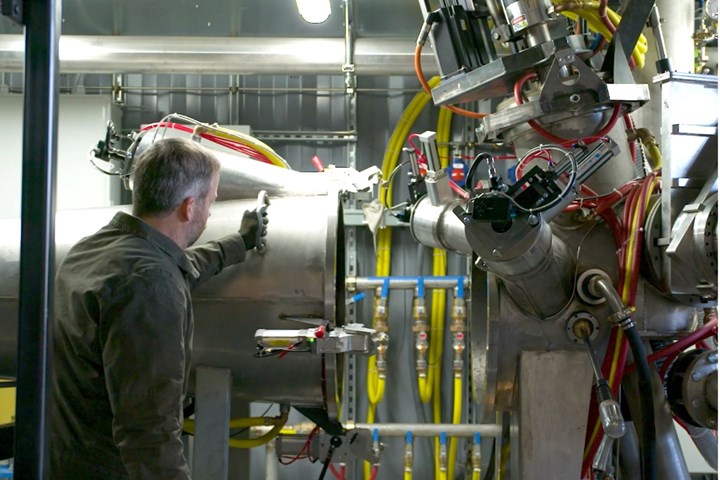

The Greyhound M2P Reactor is designed to convert metal scrap into metal powders suitable for additive manufacturing, operating within the footprint of a shipping container. Source: Continuum Powders

MolyWorks launched the latest generation of this foundry in 2023, known as the Greyhound 3.0. This updated system has been optimized for commercial operations, with upgrades that enable continuous feed without stopping the atomizer to support running larger heats. Control system updates have improved the ability to manipulate the melt pool, and the time and energy needed for pumping down have been reduced as well, Bartley says.

While MolyWorks continues to be engaged in designing and manufacturing Greyhound units, the Continuum Powders business was established in 2022 to focus on producing commercial quantities of powder using these foundries. Today Continuum Powders operates two Greyhounds in Cloverdale, California; one in Singapore; and is fielding a small fleet in a new facility in Houston, Texas.

With the updates to the Greyhound system plus the aforementioned renewable energy agreements, Bartley says each foundry will generate less than 3% of the carbon per kilogram as powder produced by traditional powder manufacturing methods, while providing equivalent atomized materials.

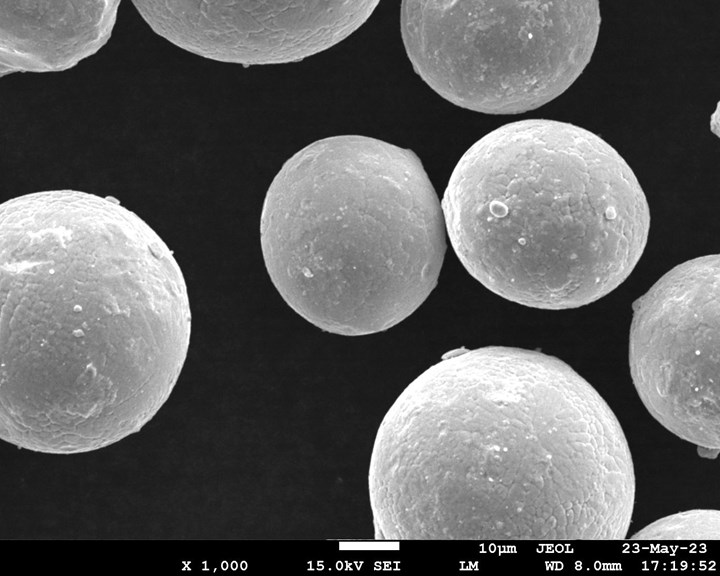

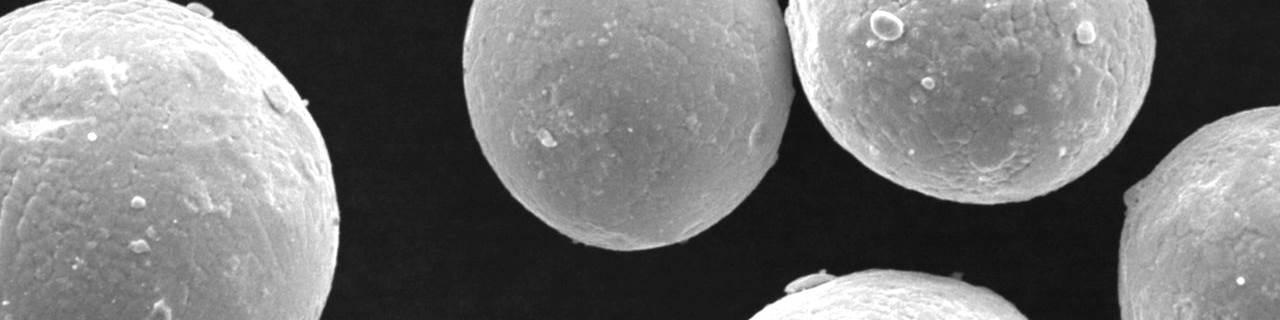

A photo of Continuum Powders’ material under a scanning electron microscope (SEM). According to the company, its powders atomized from recycled materials are equivalent to other atomized powders in additive manufacturing. Source: Continuum Powders

Small-Scale Atomization, Big Impact

Most of the company’s powder production right now focuses on Inconel 718 due to market demand, Bartley says. But as the capacity grows, Continuum Powders will diversify into other materials, likely dedicating specific foundries to specific alloys. Metal is tested and blended if needed before atomization, and the process itself is able to extract and reduce certain elements including oxygen and nitrogen to control the chemistry, making the material production process highly efficient.

While today some of the feedstock is sourced from the marketplace, Continuum Powders aims to get to the point where it is primarily atomizing end-of-life or secondary-use material sourced from customers, who would then receive the newly atomized powder in a fully circular system. This type of direct recycling could even happen on location at a customer’s site for extreme efficiency, the avoidance of shipping, and perhaps even reasons of IP control for companies that might be using proprietary alloys. Distributing recycling in this way is one of the future steps in the company’s road map.

“We want to take all the steps within our control to make sure we’re being as sustainable as we can be,” Bartley says.

Related Content

How Hybrid Tooling — Part 3D Printed, Part Metal Shell — Accelerates Product Development and Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read More3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreRead Next

Metal Powder Production From Scrap Going Global

California-based MolyWorks is shipping its second small-footprint powder production unit to Singapore, bringing sustainable material production to Asia.

Read MoreIs Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.jpg;width=70;height=70;mode=crop)