Robotic technology is becoming more flexible — literally and figuratively. Robots that incorporate new materials into their designs enable new applications for automation, including when parts vary in size and shape, as they often do in 3D printing. Soft robotics could make it easier to automate machine tending of 3D printers without having to change grippers or reprogram the system.

Soft robotics are made with less rigid materials than the typical metal and plastic, such as these silicone-based grippers from OnRobot. The flexible materials in these robots make them ideal for parts that or fragile and/or vary in size and shape. Photos provided by OnRobot.

What is Soft Robotics?

“Soft robotics” means pretty much what it sounds like. It describes robots made of softer materials, such as rubber or silicone, instead of more rigid materials like metal or plastic. According to Dr. Andrew Sabelhaus, an assistant professor at Boston University’s College of Engineering, the way soft robots move and interact with other objects is often influenced by nature, taking inspiration from elephant trunks and octopus tentacles.

Soft robotics can bring a number of advantages over hard robotics. Not only can they handle delicate parts and materials better, they’re also more flexible, meaning they can handle parts of varying sizes and shapes. But this comes with a tradeoff. As Sabelhaus points out, the softer the robot or gripper is, the less weight it can handle.

The term can refer to either an entire robot made of soft materials, or just the grippers, which can be added to full industrial or collaborative robots. Kristian Hulgard is general manager for the Americas at OnRobot, a supplier of robotic grippers and end-of-arm tooling, which offers two models of silicone-based soft grippers. He says that because many soft grippers are actuated with electric servos (including OnRobot’s), there’s a natural synergy with collaborative robots (cobots), making them essentially plug-and-play, as opposed to pneumatic grippers, which need to be hooked up to an air supply.

OnRobot’s grippers fully close around a part, making them easy to program, but more complex applications may require the use of AI in programming.

Get With the Program

Soft robotics can present a challenge in programming, particularly when it comes to applications that handle irregularly shaped parts. Usually, grippers are programmed down to the millimeter to perform the same motion over and over again, but this isn’t possible when the parts or environment aren’t always the same. Artificial intelligence could offer one solution for this challenge — Sabelhaus studies the use of AI in programming soft robots at Boston University’s Soft Robotics Control Lab.

But programming soft robots doesn’t have to be complicated. Hulgard says OnRobot’s soft grippers are programmed to open and close all the way, regardless of the part, and because they’re made of silicone, they don’t damage the part. “It’s a little bit like gripping for dummies,” he notes. This easy programming method also complements cobots, which are designed to be simple to program and deploy.

The weight OnRobot’s soft grippers can handle varies based on the part shape and size (the more the “fingers” can get around the part, the higher the payload capability), so OnRobot has a lab where customers can send parts and the company can test and prove that the grippers can consistently pick up the part.

Food processing and packaging is the most common application for soft robotics, but they are also useful for easy-to-damage materials such as acrylics, or applications where part size and shape may vary, such as in 3D printing.

Applications for Soft Robots

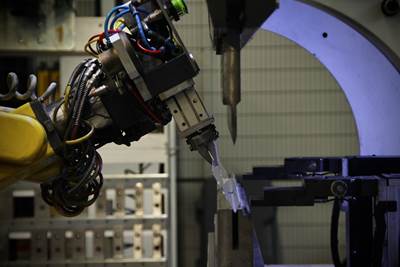

According to Hulgard, the primary application for OnRobot’s soft robotic grippers is food processing and packaging, where items are both delicate and irregular, such as fruits and vegetables. However, the company has seen industrial applications for the technology, including one customer that works with plastic parts. “The robot was gripping acrylics coming out of a large CNC mill and they needed very, very delicate gripping,” he explains. “They couldn't leave any type of mark on the part.”

Hulgard could also see potential uses for soft grippers in prototyping applications, perhaps in 3D printing, where part designs can vary within a batch. “Let’s say two differently shaped and sized parts come off the same 3D printer and you need to move them to a box to pack them,” he says. “A soft gripper would be able to grip both parts without making any adjustment to robot movement or to the gripping command itself.”

Sabelhaus also suggests other applications for soft robotics in manufacturing beyond parts handling, including assembly, exoskeletons and remote machine maintenance. “NASA loves this stuff,” he says.

About the Author

Julia Hider is a senior editor for Modern Machine Shop, where she writes about the metalworking industry. She also serves as the robotics and autonomy correspondent for parent company Gardner Business Media.

Related Content

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read More3D Printed End of Arm Tooling Aids Automation

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreRobot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Read MoreRead Next

Micro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read More8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read MoreTopology Optimization Software Enhances Gripper Reliability

Design software with built-in topology optimization and reconstruction features enabled Preziosa Francesco SRL to use Desktop Metal’s Studio System to improve the performance of a robotic gripper.

Read More

.png;maxWidth=300;quality=90)