Materialise and Renishaw Integrate Systems to Improve Efficiency of Metal 3D Printing

Renishaw system users can now benefit from Materialise’s build processor software as well as its Magics data and build preparation software.

Share

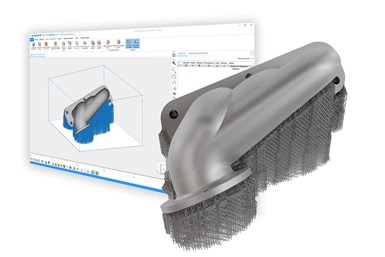

By automating support structure generation with Materialise’s software, additive manufacturers can streamline the 3D printing process. Source: Materialise

Materialise and Renishaw are collaborating in an effort to increase efficiency and productivity for manufacturers using Renishaw’s additive manufacturing (AM) systems. Through the partnership, Renishaw system users will benefit from Materialise’s build processor software tailored to the RenAM 500 series of metal AM systems.

Renishaw users will also have access to Magics, Materialise’s data and build preparation software. This will enable users of Renishaw’s AM systems to build a seamless workflow from design to 3D printed part, control and customize their 3D printing process, reduce production time and increase the efficiency of their AM operations.

For manufacturing companies looking to adopt AM to produce metal parts on an industrial scale using laser powder bed fusion (LPBF), software can enable them to unlock the full potential of the technology by optimizing the 3D printing process and streamlining the workflow. Renishaw’s scanning algorithms combined with Materialise’s accelerated build processors can shorten production time. Also, seamless workflow integration and customizable print parameters at the part level can enhance control and productivity.

“Working with Materialise enables us to support Renishaw users deploying 3D printing in a host of different manufacturing applications,” says Matt Parkes, AM strategic development manager at Renishaw. “Their next-generation build processors, in combination with their software portfolio, complement our recent technology updates. We’re pleased to be collaborating on the tools needed to support the industry as metal 3D printing becomes an essential piece of the manufacturing puzzle.”

Build processors link 3D printers with data preparation software, streamlining the AM process from design to print. Materialise’s build processor complements Renishaw’s recently launched Tempus technology. This new scanning algorithm for Renishaw’s RenAM 500 series of AM machines enables the laser to fire while the recoater moves, saving up to 9 seconds per build layer without reducing part quality. With this advancement, part build time can be cut by up to 50%. Materialise’s build processor software handles data consistently and speeds up data processing of complex geometries and high volumes of parts. Additionally, the new build processor for Renishaw AM systems enables dedicated print parameters at the part level for increased productivity and optimized quality, making it a viable solution for the volume production of different or identical parts.

“This partnership enables a unique approach to efficient metal 3D printing. The combination of Renishaw’s Tempus technology and the ability of Materialise’s build processor to process data at high speeds can significantly reduce production time,” says Karel Brans, senior director of Partnerships at Materialise. “Partnering with 3D printer manufacturers maximizes efficiency by optimizing build preparation and streamlining build jobs. This enables manufacturing at all volumes and levels of customization, allowing users to scale production.”

The build processor for Renishaw AM systems enables users to seamlessly connect to Materialise Magics. This is a technology-neutral data and build preparation software that offers compatibility with nearly all import file formats and connectivity to all major 3D printing technologies. It provides users with advanced workflow control and automation, including the recently launched e-Stage for Metal+. This software optimizes data and build preparation for LPBF systems using physics-based modeling to automate support structure generation.

Manufacturing companies can also rely on the Materialise Build Processor Software Development Kit to create their own intellectual property. The open software system enables them to build their own next-generation build processor tailored to their metal 3D printing application. Customized build processors can help to further enhance cost efficiency, production speed, and part quality, which makes it possible to manufacture intricate parts and mass produce identical or personalized products with consistent quality, reduced scrap rates, and abbreviated lead times.

Related Content

Top 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)