Nikon Lasermeister Metal DED 3D Printer and Scanner Developed for Industrial Applications, Turbine Blade Repair

This technology gives manufacturers the ability to build onto existing parts with high precision and utilize a variety of materials, reducing lead times and minimizing postprocessing requirements.

Share

Read Next

Nikon Corp.’s latest metal additive manufacturing (AM) system includes the Lasermeister LM300A which uses directed energy deposition (DED) technology, as well as the complementary 3D scanner, Lasermeister SB100. While the system’s predecessor, the Lasermeister 100A metal AM system series, is well suited for research purposes, the company says this latest solution was specially developed for industrial applications.

Building upon the processing capabilities of the previous systems, the LM300A supports an expanded build area and is also equipped with the newly developed 3D scanner, the SB100. This 3D scanner supports factory automation by enabling users to scan each workpiece with the click of a button and then automatically generates the toolpath data for the 3D printing process to begin.

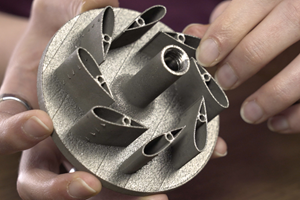

The company says the pairing of the LM300A and SB100 delivers tremendous value to the industry, particularly for applications such as repairing turbine blades and molds.

Currently, turbine blades are used in aircraft engines and power generators to help extract energy from hot gas. However, due to exposure to harsh conditions, turbine blades can degrade over time and periodically the worn-out blades must be repaired to continue usage. The traditional turbine blade repair process involves cutting and scraping the worn area for each blade, which takes time and generates waste. The blade is then manually welded for repair and grinding is performed to restore the part to its ideal shape. This repair process introduces many challenges, such as difficulties in securing highly skilled welders, which can lead to quality consistency issues and long lead times.

To address the challenges in the conventional repair process, Nikon developed the LM300A and SB100 as a solution that can reduce lead times up to 65% compared to the conventional welding process and minimize postprocessing requirements. In addition to the turbine blade example, this technology can provide great value to automobile, railway, machinery industry and other repair applications.

The system offers seamless scanning and toolpath generation. By placing a workpiece, such as a worn-out blade, inside the SB100, with a click of a button, the module begins to scan and measure the workpiece inside the chamber. It then compares its current actual shape with the CAD model to extract the difference, using a built-in, high-precision scanning feature. The SB100 then automatically generates the toolpath data for repair specific to each damaged or worn-out workpiece.

This entire process is easily completed and does not require any special skills or manual cutting of the repair area. The toolpath data is then transferred to the LM300A to initiate high-precision additive manufacturing. Once the additive process is completed, the workpiece can be placed back into the SB100, where it will scan and inspect to confirm the repair was performed to match the model. This automation and streamlined workflow can lead to reduced costs and lead time for industrial users.

The system also offers high-precision processing for various metal materials. The LM300A performs high-precision processing by leveraging advanced optical and precision control technology developed across decades of Nikon semiconductor lithography systems. In the case of turbine blade repair, the LM300A can process within the accuracy of ±0 mm to a maximum ±0.5 mm difference for the XY-axis direction and ±0.5 mm to maximum ±1.5 mm difference for the Z-axis direction, achieving ultrahigh precision. In addition, real-time laser power control by the meltpool feedback system delivers smooth surface finishing and precise processing of parts, ultimately achieving crackless repair with optimal quality and stability.

The ability to build onto existing parts with high precision and providing an advanced repair solution which is compatible with a variety of materials are key benefits of this Nikon AM technology.

LM300A supports metal materials such as Nickel based alloy (Ni625, Ni718), Stainless Steel (SUS316L), High Speed Steel (SKH51/M2/HS6-5-2) and Titanium alloy (Ti64/Ti-6Al-4V), and it is an open system, depending on customer requirements.

Related Content

Gas Turbine Swirlers: Co-Optimizing Despite the Complexity

Power generation and additive manufacturing researchers at Penn State University have joined forces to explore what impact the design of a swirler can have on gas turbine performance.

Read MoreUSNC Acquires Two Desktop Metal Printers for Nuclear Energy Solutions

The printers are said to 3D print advanced materials such as silicon carbide (SiC) — a technical ceramic with extreme environmental stability often used in aerospace, armor, plasma shield and high-temperature applications.

Read MoreGE Sells Generator Technology for Stake in EV Startup

The company says the Karno generator is expected to be 20%+ more efficient than today’s leading generators — achieved by 3D printing of thermal components and innovative fuel-to-electricity conversion.

Read MoreSafer Nuclear Energy: 3D Printed Silicon Carbide Fuel Forms

Binder jetting provides a way to create pure silicon carbide fuel structures that can withstand the harsh environment of a nuclear reactor and provide a strong barrier against the release of radionuclides.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.png;maxWidth=300;quality=90)