Magnetic 3D Printing with Fiber Reinforcement Fills Tooling Gap

Fortify’s Digital Composite Manufacturing (DCM) platform pairs high-performance resins with fiber reinforcement that can be controlled at the voxel level. The process promises a faster route to durable injection mold tooling.

Share

Read Next

Can 3D printing be made even more effective as a means of making injection molds?

It is pretty effective already. Polymer 3D-printed molds make it possible to prototype and manufacture small runs of molded parts much more quickly than with conventional molds. Metal 3D printing allows for tooling offering improved temperature control and intricate molded features. But the Boston, Massachusetts, company Fortify believes there is a gap yet to be filled with 3D-printed tooling.

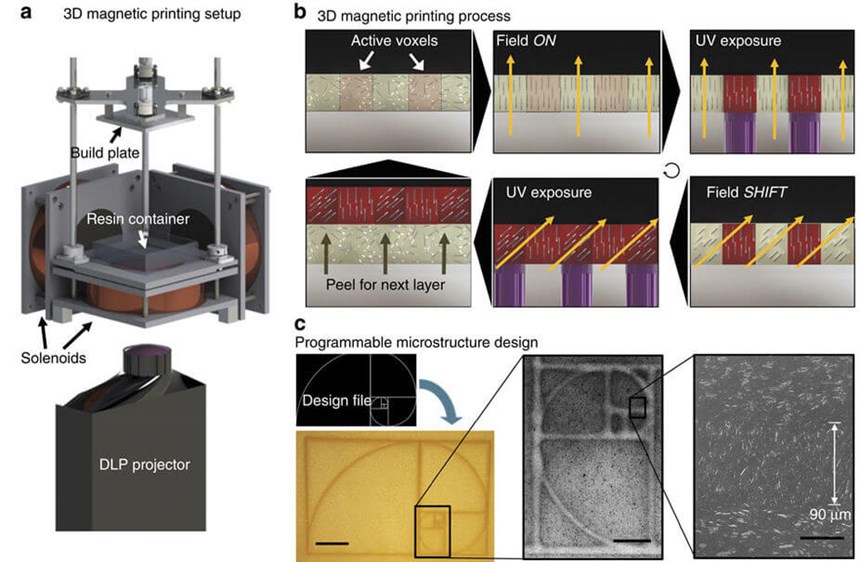

The company has developed a stereolithography-based printing process that uses a slurry of filler suspended in high-performance resin. Based on loading conditions, electromagnets align the reinforcing fibers in an optimal direction, enabling voxel-level control over the microstructure. Injection mold tooling made this way has the potential to retain the time and cost savings made possible by polymer 3D printing, while expanding material variety, extending tool life and enabling the molding of complex features that would cause failure in current molding materials, the company says.

“Looking around at the 3D printing material landscape, we found there’s a lot of unmet property space that occupies the area between pure plastics and pure metals,” says Karlo Delos Reyes, co-founder and director of business development. “There’s a lot of room to grow for plastics to be able to catch up. Our ability to reinforce plastics with high-aspect-ratio fillers allows us to push performance over non-filled 3D printing systems. Fortify has created a 3D printing platform that enables high-volume fraction composites, delivering greater strength, higher heat deflection temperatures and greater stiffness than conventional stereolithography resins.”

Magnetic 3D Printing

Fortify grew out of the Ph.D. work of Josh Martin, co-founder and CEO, which focused on the study of natural composites and biomimetic composites. By applying the same principles to synthetic materials such as carbon fiber and fiberglass, Fortify has created a 3D printing platform that supports high density, high-fill composites delivering greater strength, higher heat deflection temperatures and greater stiffness than conventional stereolithography prints. The company’s proprietary Digital Composite Manufacturing (DCM) platform combines 3D printing, electromagnets and specialized materials to produce composite parts with targeted mechanical properties.

DCM relies on Fluxprint, Fortify’s magnetic alignment processing system. Electromagnetic solenoids surround the resin container within the printer, applying a magnetic field while the processor is polymerizing the resin with UV light. Carbon or glass fibers suspended within the resin are oriented by the magnetic field on a voxel-by-voxel basis to provide part strength exactly where it is required. Driving this microstructure is Fortify’s Intelligent Fiber Orientation Method (INFORM) software, which determines from FEA data how best to align the fibers in each section of the part to meet the required stresses and strain.

“By adding aligned reinforcement, we can push tooling performance and use more intense plastics such as polycarbonates, nylons and different fiber-filled thermoplastics.”

The starting material in DCM is a slurry of high-performance resin containing reinforcing fibers.

“The crux of all the SLA-based tooling resins is that they look good and you can hit tolerances, but you’re not able to injection mold many high-performance plastics just because of the pure mechanics of these materials,” Reyes explains. “By adding aligned reinforcement, we can push tooling performance and use more intense plastics such as polycarbonates, nylons and different fiber-filled thermoplastics.”

But material development is not simply a matter of adding fibers to a resin; they must be carefully tailored to work together. “If the surface chemistry between the fiber of choice and the resin isn’t properly tuned, it can actually act as a void,” Martin says. Specialized additives keep the fibers evenly distributed throughout the resin.

So far, Fortify has developed three main materials: a ceramic-filled resin with high stiffness and heat deflection used for injection mold tooling; a fiber-reinforced high-strength resin; and a high-toughness, high-heat resin developed in collaboration with a chemical manufacturer and intended for automotive applications.

Future material developments could also push Fortify into new applications. “Changing the filler that goes into the resin has a big effect on the final properties,” Martin says. “Right now we're focusing on structural improvement, but in the future it could go towards improving thermal conductivity, or electrical conductivity in the case of an electrostatic dissipative (ESD) material.”

Injection Mold Tooling and Beyond

Though DCM is suitable for producing prototypes and end-use parts (Reyes and Martin see potential in UAV and CubeSat applications, especially), it is particularly adept at creating injection mold tooling. DCM has several advantages over traditional moldmaking methods, in that it reduces lead time, saves cost, and opens up new design possibilities and features that would otherwise mandate complicated manufacturing methods. Meanwhile, unlike metal 3D-printed mold tooling, DCM produces a smooth-enough surface finish to allow tools to be manufactured to net shape, no postprocessing required. And, the use of filled resins expands the variety of materials that can be molded in a 3D-printed tool to include high-temperature materials such as polycarbonate and nylon.

DCM also has the speed advantage, enabling Fortify to get batches of injection molded parts in customers’ hands as much as six weeks faster than the conventional method of making a tool. “That’s six weeks that these groups can harvest critical data on different design specs,” Martin says, and that quantity of molded parts is greater than what 3D printing would typically allow.

In a recent example, Fortify made an injection mold for its customer Catalysis Additive Tooling, which provides design, tooling and manufacturing services to OEMs through a network of partners. Catalysis had determined that a mold made with digital ABS for this part (shown above) would start to fatigue, soften and crack after about 40 or 50 shots. Instead, Fortify manufactured a tool using its ceramic-filled material. The injection molder was able to shoot the full run of more than 150 parts in polypropylene with no decrease in tool performance. The molder then decided to stress-test the tool, successfully making an additional 50 parts from nylon, a material that would not be possible to shoot in a non-filled polymer tool.

“That tool is still alive and well,” Reyes says. It’s not yet clear what the upper bound might be for DCM tooling, but the durability of these tools thus far holds promise.

Fortify is currently providing parts out of its Boston facility, but plans to launch a beta program in late 2019 to offer its printers and materials to external customers.

Related Content

3D Printing Supports Induction Coils — and Emergency Needs

As a participant in Michigan’s Project DIAMOnD initiative, Tucker Induction Systems received a 3D printer to use any way it saw fit, provided the capacity remains available in case of emergency. Use cases and lessons learned as part of this distributed manufacturing network.

Read MoreEaton Developing Carbon-Reinforced PEKK to Replace Aluminum in Aircraft Air Ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreVideo: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreRead Next

Fast-Tracking the Supply Chain with 3D-Printed Tooling, Strategic Partners

Catalysis Additive Tooling is building a one-stop supply chain for production quantities ranging from one to one million. 3D-printed tooling and relationships are key.

Read MoreThe Right Design, Material and Machine Combination Takes the Risk Out of 3D Printing Molds

Full-service design and mold delivery, moldmaking materials, and a low-cost, high-precision printer minimize the technical risk of 3D-printed mold tryout.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)