MPI Launches AI Project to Create Material Reuse Management Tool for Metal 3D Printing

MPI is working with Additive Manufacturing Solutions and AMFG to create a versatile, commercial predictive material reuse management tool that will enable additive manufacturing to expand by introducing greater cost efficiencies.

Share

Read Next

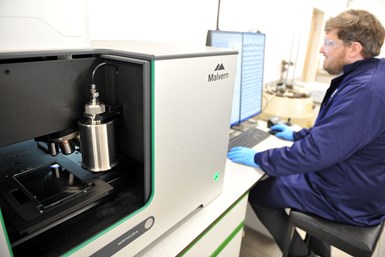

The SMART-APP is being developed to predict the quality change of the powder after each process and propose alternative process parameters on used powder to extend its life span with a minimal or an in-specification impact on product quality. Source: Materials Processing Institute

The Materials Processing Institute is leading a £600,000 research collaboration to develop a groundbreaking artificial intelligence (AI) tool capable of creating greater efficiencies within the additive manufacturing (AM) sector.

Working in partnership with Additive Manufacturing Solutions and AMFG, the collaboration aims to provide a versatile, commercial predictive material reuse management tool that will enable AM to expand by introducing greater cost efficiencies.

Known as SMART-APP, its goal is to enable world-class production of AM components, using laser powder bed fusion through the introduction of smart predictive models for resource efficiency and waste reduction.

SMART-APP aims to predict the quality change of the powder after each process and propose alternative process parameters on used powder to extend its life span with a minimal or an in-specification impact on product quality.

The project is funded by Innovate UK, part of UK Research and Innovation (UKRI), the UK’s innovation agency, which drives productivity and economic growth by supporting businesses to develop and realize the potential of new ideas.

One area of particular interest is the growth of metal AM which is not yet cost-effective due to a development gap in the level of powder waste and length of processing time.

The research will feature state-of-the-art materials characterization and mechanical testing, investigating shelf life and the processability envelope of environmentally affected common stainless steel, titanium and superalloy base feedstock. It will also examine methods of reclaiming the powders and the effect on the final product.

The resulting outputs will be fed into an advanced database linking powder input properties against AM part performance to provide a predictive tool that will be available for industry to use.

“SMART-APP is the next logical step to continue the work the Institute has already undertaken in powder characterization,” says Nick Parry, MPI industrial digitalization group manager.

Developing this artificial intelligence tool can help AM users create faster and cheaper ways of maximizing powder reuse, and aid the AM industry as a whole, especially those needing to maximize the operational effectiveness of their machines.

“This predictive tool will develop and enable world-class production of AM components, with smart solutions for resource efficiency and providing longer use of materials feedstock and reducing wastage,” Parry says.

AMS is gratified to have the support of Innovate UK to continue developing its portfolio of powder and AM process optimization capability. “This marks our first step toward a groundbreaking approach for dynamic materials management,” says Rob Higham, Additive Manufacturing Solutions CEO. “The potential of the AM process remains a potential in many people’s eyes. It could be realized with the development of a versatile and smart predictive tool for tracking powder quality after each reuse.”

AMFG, a software company providing MES and workflow automation for manufacturing, is part of the this initiative which aims to transform AM toward more resource-efficient methods. “SMART-APP aims to instil trust in the additive manufacturing realm by forecasting powder quality and recommending processes to restore desired powder properties for reuse,” says Alexander Grimmer, an AMFG technical consultant. “AMFG eagerly anticipates contributing to a cutting-edge material management system in this project, poised to deliver substantial environmental and economic benefits to the industry. This endeavour is set to expedite the widespread adoption of additive manufacturing.”

Related Content

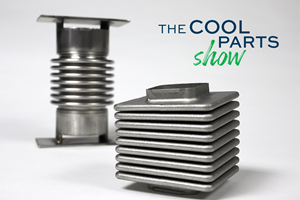

Flexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

Read MoreDrones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More