3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Mantle has a 3D printing process focused on making injection mold tooling. The company recently began shipping production versions of its system to molders and moldmakers.

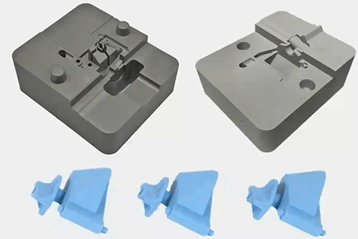

The unusual process, which the company calls “TrueShape,” starts with a metal paste. Injection mold cores and cavities are 3D printed from this material and the form is shaped to precision via CNC machining.

The full hardness of the tool is then realized in a controlled sintering operation that is also part of the company’s process. The result is tooling in H13 or P20 tool steel that is ready for production-scale injection molding, but obtained with fewer steps and in less time compared to conventional moldmaking. I visited Mantle’s facility in California, and learned this explanation of the steps in the process.

Mantle TrueShape FAQ

What is Mantle’s 3D printing system used for?

Mantle’s system, called TrueShape, is an alternative process for making injection mold tooling. It is a combination of printing, machining and sintering to produce 3D printed metal injection mold tools.

What is the Mantle TrueShape system comprised of?

In broad strokes, it is comprised of:

- Software.

- A machine that deposits material and shapes the part.

- A sintering furnace.

The machine is based on a CNC machining center and includes 10 different cutting tools, thermal and visual imaging sensors, and dust mitigation. The print material is a flowable metal paste that is loaded via cartridges just over one foot long and three to four inches in diameter.

To which additive manufacturing family does Mantle’s TrueShape belong?

- The process falls under the material extrusion family, in that TrueShape mold tools are built by extruding then shaping metal paste. But these parts also require a separate sintering step to solidify them, similar to binder jetting.

What are the benefits of Mantle’s TrueShape system?

In comparison to conventional methods of producing injection mold tools, it:

- Is potentially faster and cheaper.

- Consolidates processes.

- Produces molds out of the same tool steel used in conventional methods.

- Produces tools with the same performance as those made through conventional methods

What material is used in Mantle’s TrueShape system?

A flowable metal paste goes into the system and, after sintering, becomes H13 or P20 tool steel.

Different ingredients of the final metal are suspended in the paste. Separating the elements before sintering allows for tighter precision as the different ingredients sinter at different temperatures.

The entire sintering cycle can be controlled. In fact, the software component that compensates for shrinkage during sintering is tuned not just to the material, but to every single batch of the material. The user selects which batch is in the machine and correction factors for shrinkage are incorporated into the tool paths based on the particular batch of material.

What is the process for Mantle’s TrueShape?

- Deposit paste (print)

- Shape the paste (machine)

- Dry the paste

- Remove the part

- Sinter

Steps 1, 2 and 3 are repeated over and over until the final shape is constructed. Deposition happens in layers of approximately 100 microns. After each layer there is visual and thermal imaging that's done for process control, and then the drying step to remove moisture in the paste which later helps to limit shrinkage in sintering. CNC machining (step 2) happens approximately every ten layers. The machining is referred to by Mantle as shaping because it is not performed at the full hardness of the material.

How long does the Mantle TrueShape process take?

A green part can be printed and shaped overnight. The final sintering process takes between 30-40 hours.

How precise is the TrueShape process?

Due to control over material shrinkage, Mantle promises a precision of 0.001” per inch of the part.

How long do the TrueShape molds last?

Results can vary, but in the case of Tessy Plastics, the molds surpassed 1.65 million cycles in under two years and are still in use. The company says they are comparable to conventionally produced molds.

What companies are using TrueShape?

- Westminster — for prototype medical devices

- Tessy Plastics — for a deodorant stick mold

- Nicolet Plastics — to produce molds for its client Gamber Johnson

Learn More About Mantle

Mantle’s 3D printers are the most efficient way to produce mold and die inserts with the accuracy, surface finish, and tool steel properties demanded by toolmakers.

Related Content

Taking the Leap into Additive Manufacturing

SolidCAM’s partnership with Desktop Metal, and its in-depth experience in combined metal 3D printing and CNC finishing, is aimed at making additive manufacturing accessible and profitable for job shops and other manufacturers.

Read MoreHow to Improve Polymer AM Productivity 20X

A fast cycle time is critical to efficient production 3D printing, but it’s not the only thing. How you choose the right parts for AM, prepare jobs for production, and manage post processing will have just as big an impact on total 3D printing throughput. It all needs to work together to achieve maximum productivity.

Read MoreMantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreRead Next

Over 1 Million End Parts Produced With Mold Made on Mantle Metal 3D Printers

Over 1 million end-use plastic parts produced using mold tooling made via the TrueShape system for making precise steel tooling rapidly using 3D printing.

Read MoreMantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read More