Share

Read Next

From a distance, metal additive manufacturing would seem to be a fitting capability for a metalworking CNC machine shop. Both 3D printing and machining offer means of producing discrete metal parts. But get closer, and the fit is less apparent. The most common metal AM capability for production, laser powder bed fusion, involves material handling and workflow considerations different from machining, not to mention an equipment cost apt to be high relative to machine tools. As a result, for many machine shops, their use of 3D printing is limited to deposition-style fused filament fabrication (FFF) in polymer. The low-cost, easy-to-use 3D printing make fixtures, prototypes and work aids — and this is as far as additive goes for a large number of metal part producers.

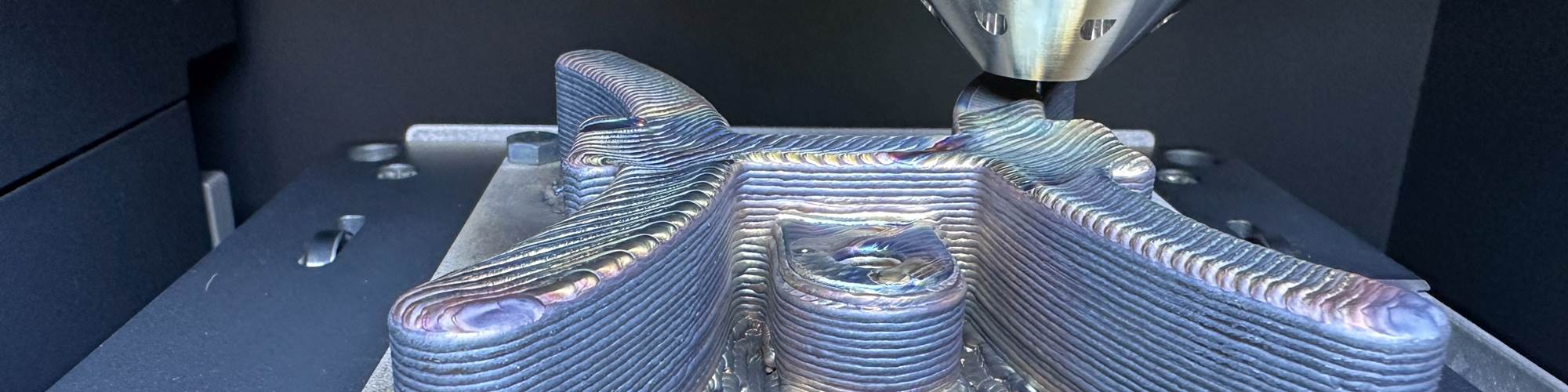

Meltio's M600 is a directed energy deposition metal 3D printer designed for a shopfloor environment. The geared shaft in the foreground gives a sense of the size of part it has the capacity to produce.

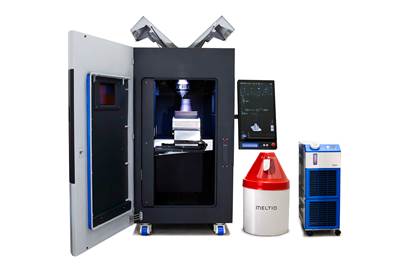

But a new system from metal AM equipment maker Meltio illustrates what could be seen as a next increment of metal 3D printing technology, promising to let AM go farther for established manufacturers. The company’s M600 metal 3D printer, among other things, offers a direct response to the compromise described above. The system looks and operates much like an FFF polymer 3D printer, but it 3D prints metal parts across the spectrum of weldable alloys. The machine offers an example of the continued advance of metal additive in terms of its accessibility to a broader range of users.

The new Meltio system (like all the company’s machines) uses directed energy deposition (DED), not laser powder bed fusion (LPBF). The material form is wire, and while the machine maker supplies this material, commonly available welding wire can also be used. The machine employs a laser to melt this metal and it relies on argon gas for the inert environment, two elements peculiar to metal AM — so the comparison with a polymer 3D printer is not perfect. But the operator’s straightforward interaction with the machine and the lack of any necessary downstream steps (no sintering is needed, for example) resemble 3D printing the way many machine shop users experience it today.

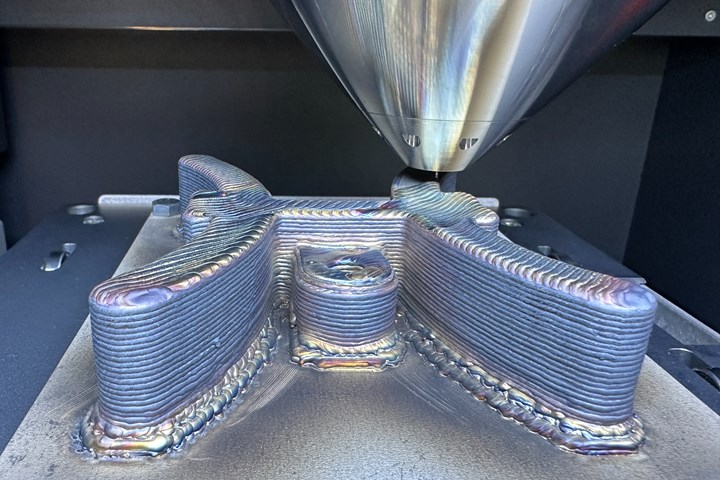

The machine's feedstock is wire. Melting happens outside the nozzle. Changing material is a matter of retracting one wire and feeding another, allowing for multimaterial parts to be 3D printed in a single build.

Meltio's Lukas Hoppe shows the machine's wire carriers. Two other spools like this mount on the opposite side of the machine, which can employ up to four materials at once. For large unattended builds, a larger-capacity external wire drum is also an option.

Meanwhile, the system will not do machining. The DED 3D printer is not available as a hybrid, and Meltio R&D director Lukas Hoppe says it is unlikely it ever will be. “In production, the problem with a hybrid is the shop only gets access to 50% of the machine [either 3D printing or machining] at any time,” he says. Instead, this is a metal 3D printing unit for about the same price as a mid-range machine tool, and it is intended for operation in conjunction with, and within the same workflow as, CNC machines.

The Problems Metal AM Solves for Machine Shops

Quick sequential turnaround of smaller parts is one of the more nimble use cases for the metal 3D printing system, but it can also be run continuously to create larger components. This stainless steel U joint is about 200 pounds and was 3D printed in about 200 hours.

I attended a launch of the new machine held near the company’s headquarters in Linares, Spain. At this event, company applications engineer Manuel Calvache gave a talk making the case for metal 3D printing in a machine shop. The capability provides a solution to three challenges machining businesses today routinely confront, he notes. They are:

- The need to interrupt production on machine tools to make custom workholding using those same machines.

- Long lead times for parts made of high-value metals, often resulting from a wait for castings or forgings in those materials.

- Work that must be turned down, because the job involves a challenging material or geometry the shop is not confident it can economically machine.

All these challenges suggest AM, he says. And for machine shops, adopting AM presents a choice of polymer or metal 3D printing. Polymer is easier, but of limited use — it can address problem one, not two or three. By contrast, he says, metal 3D printing has tended to ask a lot: LPBF generally involves a high initial investment, safety considerations around handling powder, operator skill beyond what is involved in machining, and the need to design and produce part geometries not typical of machining. Meltio developed the M600 as a bridge between these two realms.

An example of a multimaterial application. This combustion chamber is copper on the inside, Inconel 718 on the outside, all 3D printed as one piece.

In fact, applying DED to problems two and three from the list above offers solutions that go well beyond the range of choices machining makes available. The M600 system provides capacity for four spools of wire, meaning up to four different materials can be applied in a single 3D printing build. The operation of the nozzle, which melts material outside the nozzle itself and can therefore change wire just by retracting the feed without any nozzle clearing, allows for switching back and forth between metals as a programmed part of the build. The system’s use of a blue laser expands the metal range, allowing for melting reflective metals (like copper and aluminum) precluded by earlier systems. All of this together brings the potential for multi-metal solutions, Calvache says. One possibility is to 3D print a part inexpensively by using a lower-cost metal for bulk, applying a more expensive metal only at the outer surface where hardness or corrosion resistance is needed. Or, for heat-conducting parts, the bulk of the part could be 3D printed from copper for heat transfer, while the outer form is made from a more durable material such as Inconel or stainless steel.

Adding AM to Machine Shop Workflow

Meanwhile, certain other possibilities are new to this machine but long-established for CNC machine shops. Because Meltio’s M600 is larger than an earlier model (the company’s M450), new features are possible. For example, the machine makes full use of probing, just like a machine tool. The company’s earlier system used probing only in the Z axis to locate the surface of the build plate, whereas the new machine features probing in three axes.

In addition, “The newer machine is big enough to incorporate industrial workholding solutions,” Hoppe says, such as quick-change zero-point clamping using the same third-party system that might be in use on a shop’s machine tools.

These two capabilities together — machine tool workholding and probing — allow for a workflow that can cleanly integrate additive and subtractive operations, Hoppe says. A part could be machined, then sent to 3D printing for a complex feature to be added to the part, then sent back to the machine tool for finish machining of that new feature. Zero-point clamping and probing for location would assure minimal delay at each of these steps.

Indeed, in broad terms, it is this different workflow the M600 makes possible (compared to other metal AM systems) that suits it for use in an existing production environment such as a machine shop. Hoppe says, “Once you generate a slice file, you are only a minute from 3D printing. The bed is probed, but no other step like heating up the chamber is needed. That means one-piece flow makes a lot of sense.” He adds, “I do not see metal AM fully succeeding if it does not ultimately find a way to go into machine shops.”

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read More3D Printed Metal Component for CNC Machining Center: The Cool Parts Show #47

Machine tool maker DMG MORI improved this coolant delivery adapter by making the part through additive manufacturing instead of machining. One of the viewer-chosen winners of The Cool Parts Showcase.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

Meltio, One Off Robotics Develop Robotic AM Work Cell for Cost-Effective, Reliable Metal Part Production

The system offers a deposition rate of up to 1 kg/hr to create clean parts that are fully dense and mechanically equivalent or superior to those created from traditional manufacturing.

Read MoreNavy Improves Readiness of USS Bataan With 3D Printing Capability

Crew of USS Bataan completed the first metal 3D part fabrication and replacement for a de-ballast air compressor in only five days using a permanently installed metal 3D printer, demonstrating the impact this technology can have on operational readiness.

Read MoreMeltio M600 Wire-Laser System Reduces Material Waste, Lead Times While Increasing Manufacturing Flexibility

The Meltio M600 can seamlessly integrate into machine shops and production environments, enabling not only the printing of entire metal parts but also the addition of features to existing components and the repair of damaged surfaces.

Read More