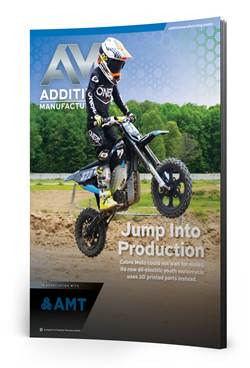

July/August 2022 Issue

July 2022

Digital Edition

Features

Featured articles from the July/August 2022 issue of Additive Manufacturing

Lossless Recycling of E-Waste Into Additive Manufacturing Powders

Germany-based Reco E-Waste transforms copper and other metals from electrical components and electronics into high-value powders for additive manufacturing in a 1-to-1 process.

Read More

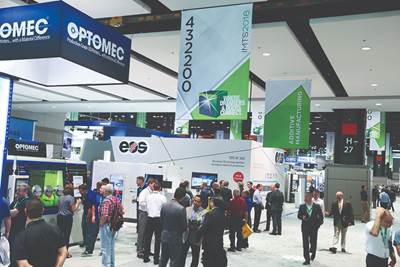

Digital Manufacturing. Implemented.

Additive manufacturing technologies have accelerated to improve performance, lower life cycle costs and help reshore production, all of which are helping to revolutionize manufacturing. Check out the latest AM technologies at IMTS 2022 and learn how these technologies can improve your bottom line.

Read More

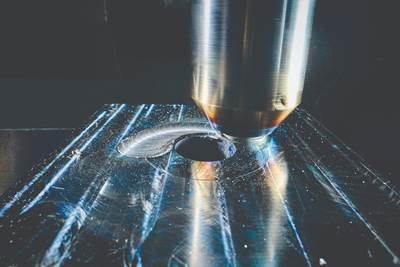

Hybrid Manufacturing Turns Design Inside Out

Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition for additive manufacturing and friction stir welding, enabling manufacturers to design products from the inside-out.

Read More

3D Printing as a New Product Launchpad

With 3D printing, Minnesota manufacturer Resolution Medical offers a fast, affordable route for individuals and small to medium-sized businesses to get new medical devices and other products off the ground and into the marketplace.

Read More

Binder Jetting Follows in Footsteps of Metal Injection Molding

For Smith Metal Products, additive manufacturing helps MIM customers finalize the design, but production opportunities are waiting.

Read More

Using (And Scaling) FDM 3D Printing for Production

Maxwell June’s razor press, which is designed to combine the ease of use of a disposable razor with the environmental and cost benefits of a wet shaving system, is made via FDM 3D printing. How did the company make this choice, and how does it plan to scale up?

Read More

Plastics Assembly Expert Joins Development and Production via 3D Printing

Manufacturing technology supplier Extol has always served customers who are producing polymer parts. Now, it is making some of those parts in-house through 3D printing, providing new options ranging from functional prototyping into bridge production and beyond.

Read More

Get Smart(er) While You Watch

“Smart(er) Shop” — brought to you by Autodesk — is a new IMTS+ show addressing analog shopfloor problems by applying affordable, easy-to-install digital solutions.

Read More

Flexing Thermoset Polymers Into Production 3D Printing

Chromatic 3D Materials develops tough and flexible thermosetting urethanes for additive manufacturing. The resin formulation is only part of the path to scale.

Read More

Bridge Production Is Real Production

Not prototyping — it is something far more than this. The chance to launch the product into the world using additive manufacturing as the initial process delivers important new possibilities, and even keeps on delivering advantages far into the product’s life.

Read More

Can Metal Parts Be Replaced With 3D Printed Composites?

High performance materials such as carbon PEEK have allowed Werco Manufacturing to 3D print parts for aircraft trainers that function like metal. But can this extend to end-use aircraft parts?

Read More