As the automakers centered in Detroit have been chasing electrification and faster, more agile product development, a manufacturer on the other side of the state of Michigan has felt a shift in the supply chain for polymer parts. In the past, vehicle development was slower, more in line with the lead times expected for injection mold tooling. If new plastic parts couldn’t be sourced in time, automakers often had the option to pull from inventory developed for previous years’ models to get cars into testing and fulfill early purchases. But electric vehicles often don’t have this luxury; whether developed by startups or legacy OEMs, EVs tend to be new vehicle platforms without legacy parts to fall back on — and they are being launched into the market at accelerated rates, creating a demand for faster production.

Indeed, the overall vehicle design cycle has dropped from four years down to two, says Andrew Roderick, senior applications and sales engineer at Extol, the aforementioned manufacturer located in Zeeland on the west side of Michigan. If an injection mold takes 3 to 6 months to obtain, that means a wait that was once maybe an eighth of the total development time might now take up to one-quarter of the entire cycle. And if legacy inventory isn’t a viable option for these new vehicles, automakers are left scrambling for parts and their suppliers are challenged to deliver them.

But for Extol, this shift and the timeline compression it brings present an opportunity. The company has been in business for more than 35 years providing automated systems that perform various joining operations on plastic parts, often parts that will go on to be used in cars. But now Extol is no longer only assembling discrete parts made elsewhere; it is producing its own, through Multi Jet Fusion (MJF). The polymer 3D printing process has turned Extol into a parts producer, and one uniquely positioned to serve the accelerated timelines of the development of vehicles and other products.

Previously, Extol might have received molded plastic parts late in the product development cycle and been charged with automating the process to assemble them. Now, the company is entering the development cycle much sooner as a manufacturer of plastic parts through 3D printing (though its expertise in joining plastics remains relevant — see the hot staples holding together the pieces of this manifold).

3D Printing Supports Different Lifecycle Steps

Extol’s primary business segments are plastics assembly technology and custom automation systems to apply it. The company has deep understanding of the options available to unite different plastic components, from laser, ultrasonic and hot plate welding to its proprietary NanoStake process. These joining techniques are provided to customers within fully tooled and automated machines; the company will also provide joining services for low volumes of parts — a few hundred or a couple of thousands — while the machines are in production.

Kyle Harvey, business unit manager, explains the company’s NanoStake and Infrastake technologies. These machines apply heat to plastic bosses, transforming them into stakes that hold parts together. The company provides custom automated solutions for heat staking, welding and other means of joining plastic parts.

Customers for plastics joining technology and services range from Tier One and Two automotive suppliers to medical device manufacturers to consumer goods providers. Although Extol’s additive manufacturing capabilities are much newer than these other technologies, the customer base making use of the company’s three MJF printers from HP does have significant overlap with its typical clients. Companies feeling the pressure to bring products to market faster, to iterate designs while at the same time pursuing sales, and to put off mold purchases for as long as possible are finding a solution in polymer 3D printing — and they can access that solution through a supplier they might already know.

“It’s the same customer base to some extent,” Roderick says. “But we’re now supporting different parts of the lifecycle.”

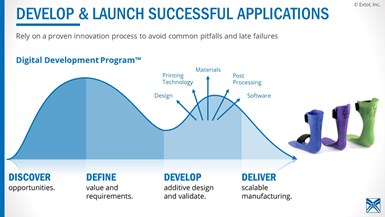

In the past, Extol has mostly dealt with plastic parts near the end of their production cycle. Adding 3D printing has meant developing a system for working with customers much earlier in a product’s lifecycle to ensure a successful launch. Slide: Extol

Rather than stepping in at the end of development to help automate joining processes that support production, Extol is now jumping in at the beginning of a product’s lifecycle, and taking part in the early stages of product development. This has entailed developing frameworks and methodologies to get at customers’ true goals. It has meant being open and flexible with design changes, collaborating with clients to get it right. And it has meant taking on part production to support both initial and ongoing sourcing needs.

Previously, Extol might have been receiving hundreds of prototype injection molded parts to assemble with prototype tooling at its Process Development Center in Zeeland. Now, it is leveraging 3D printing to produce short runs of maybe 20 or 30 parts at a time before proceeding with assembly. The production capability means that customers can develop new products faster and get functional parts into testing sooner, before investing in mold tooling. This 3D printing work perhaps sits somewhere between “functional prototyping” and “bridge production,” but either way, the deliverables are functional, end-use parts just provided in lower quantities lower than full scale.

An example of how 3D printing supports design changes during production of functional prototype parts. Extol produced 52,000 of these automotive interior cartridges through Multi Jet Fusion. The parts went through three iterations during this production run, allowing the customer to dial in the design before kicking off a production mold tool.

Meanwhile, bridge production also offers opportunities to enhance the design. The automotive interior cartridges pictured above represent a large 3D printing production job for Extol; there are four SKUs in the job (right and left versions of two components) and the full production run amounted to 52,000 parts, or 95 MJF builds. But unlike a typical serial production job where parts are made identically every time, additive as the production technology allowed the automotive customer to continue to iterate (in this case, three different times) even as it started to put cars into testing and into the market.

Sometimes the changes are even faster. A production run of bezels for automotive sensors, for instance, saw the same number of design iterations within a much smaller quantity.

“Within 500 parts that we printed, they made three changes,” says Kyle Harvey, business unit manager for additive manufacturing. This is not just additive manufacturing taking over production; it is a different kind of production all together.

Extol’s production 3D printing capacity consists of three HP Multi Jet Fusion machines, three unpacking stations, and a vapor polishing unit from Additive Manufacturing Technologies. The company typically runs two short builds during the day while the building is staffed and three builds overnight, six days a week.

Joining New Markets

Automotive applications make up about 60% of the work currently being performed on the Multi Jet Fusion 3D printers. But this 3D printing capacity is also allowing Extol to find new business opportunities in additional industries, beyond those it has traditionally served.

“We’re adding value for the customers we already have, and diversifying business at the same time,” Harvey says.

The orthotics and prosthetics market is among those diversification opportunities. Newer customers include Fited, which provides scoliosis braces, and Spentys, a supplier of braces, splints and similar devices. These parts are production products as well, but they are needed in batch sizes of just one — each item is unique to the patient.

This Spentys brace was designed from a scan of the patient’s wrist, printed from TPU and finished using vapor smoothing. The result is a flexible, comfortable device that also looks and feels like more conventional materials.

They are also larger parts, which can pose difficulties in build planning. Fewer parts per build means less efficiency and reduced printer utilization, which hinders Extol’s ability to scale. “Making one large part is easy, because you can pack other small parts in around it,” Harvey says. “But making 100 is challenging; it fills the build and takes up too much space.”

This scoliosis brace from Fited could fit inside the MJF build volume in one piece, but printing such a large part whole has trade-offs. Instead, Extol prints each brace in 10-15 pieces, which brings down the price and potentially shortens the build time. Ultrasonic welding joins the pieces. (Look familiar? This part was a finalist in The Cool Parts Showcase contest for 2021.)

Fitting a single part as large as a scoliosis brace into the MJF build volume is possible, but not efficient. The solution to this challenge is something the company already knows well: joining. Rather than print each brace whole, Extol divides the print into 10 to 15 discrete parts. These smaller pieces can be more easily nested into the envelope with other jobs for better printer utilization; their smaller size may also lower the build height and therefore reduce print time. Once depowdered, the parts are ultrasonically welded together to achieve the same result.

“We’re not scared of assembly,” Harvey says, and this allows the company to realize the benefits of printing parts in pieces. “Splitting large parts saves cost, improves throughput and makes printing faster.”

In addition to parts for customers, 3D printing is also used to produce key components in Extol’s standard and customized assembly systems — like this end of arm tool (EOAT) for a robot. Photo Credit: Extol

Functional Parts, Fast

Currently more than 90% of the 3D printing performed at Extol is for outside clients, but the company has benefited from this technology internally as well. It has also become a valuable tool in developing and manufacturing the company’s own automated systems including its NanoStake and Infrastake products. The NanoStake product alone has 10 different 3D printed components, made with technology from HP, Formlabs and Origin. Handles, button covers, HMI casings, custom fixtures, robot end of arm tooling (EOAT) and more have been produced through 3D printing for the automated joining equipment the company provides.

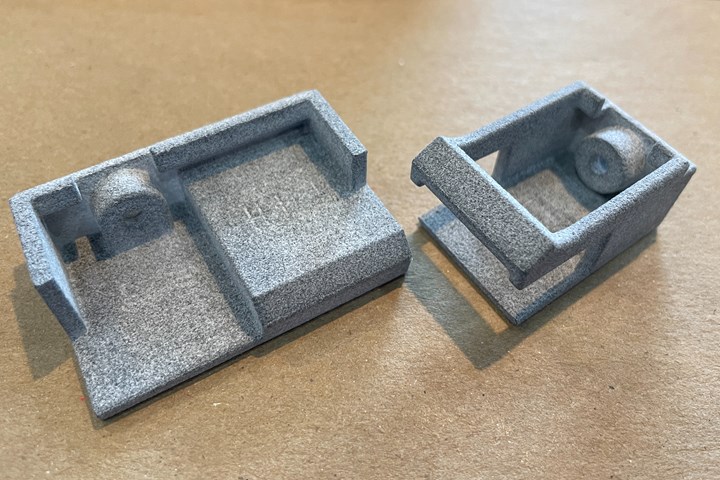

3D printing was used to iterate and produce a critical component inside Extol’s NanoStaking machines: a tiny electronics holder needed inside each one of these NanoStake modules.

Photo Credit: Extol

Perhaps the most striking example of how 3D printing has accelerated and improved Extol’s own equipment development is a component not even visible in the final product: a tiny electronics holder used in the company’s NanoStake products. These systems perform precise heat staking, a process that quickly heats and cools a punch to form a plastic boss into a stake that holds parts together. The electronics holder was originally designed for injection molding, but the company decided to pursue production through 3D printing instead. This choice opened the door to new design possibilities as well as rapid iteration through the company’s in-house Formlabs printers. The initial AM design to launch took only two weeks, and design improvements for manufacturability continued even after launch.

3D printing for design iteration, illustrated. Andrew Roderick points out the various versions of the electronics holder that were tested, including many 3D printed designs.

The part is now produced using Origin technology by an outside provider, but its journey illustrates what might be the great promise of additive manufacturing for new products. AM may never deliver quantities competitive with injection molding, but its benefits are more relevant early on, in the development phase of the lifecycle. The ability to obtain functional parts right away through 3D printing gives OEMs the power to accelerate their timelines, to iterate designs, and to arrive at the best possible product as quickly as possible, whether it be a piece of industrial equipment or the next generation of electrified vehicles.

Related Content

8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreRead Next

3D Printing as a New Product Launchpad

With 3D printing, Minnesota manufacturer Resolution Medical offers a fast, affordable route for individuals and small to medium-sized businesses to get new medical devices and other products off the ground and into the marketplace.

Read MoreUsing (And Scaling) FDM 3D Printing for Production

Maxwell June’s razor press, which is designed to combine the ease of use of a disposable razor with the environmental and cost benefits of a wet shaving system, is made via FDM 3D printing. How did the company make this choice, and how does it plan to scale up?

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.jpg;width=70;height=70;mode=crop)