Hybrid Manufacturing Turns Design Inside Out

Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition for additive manufacturing and friction stir welding, enabling manufacturers to design products from the inside-out.

Share

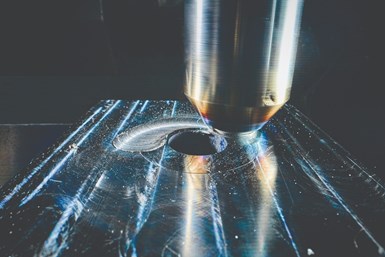

A rotating FSW tool plunges into the workpiece, dwells momentarily to enable rotation, friction and pressure to create a plasticized material pool, then traverses the workpiece to create the weld. Photo Credit: Mazak

Traditional manufacturing starts with a solid block of metal. Manufacturers think about how to mill, turn, grind and polish the part, move the part to the next manufacturing step, create subassemblies and bring parts together. Each activity occurs in distinct processing areas. Hybrid manufacturing disrupts that workflow.

Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition (LMD) for additive manufacturing (AM) and friction stir welding (FSW). “Instead of designing products from outside-in, we can design from the inside-out, such as by sealing seam and then milling features. That’s really a paradigm shift in the way engineers think,” says Dale Fleck, general manager, Mazak MegaStir (IMTS booth: 338300).

Instead of using a stand-alone FSW system, which may have lower utilization rates, Mazak offers an alternative with its VTC-300c hybrid system, which offers everything users expect from a three-axis CNC, except that its powerful, 40-taper spindle also accepts FSW tools. Instead of multiple workstations, some parts can be “done in one.” This removes the time and labor associated with moving parts between machining and welding stations. It also removes potential sources of error, such as losing zero due to refixturing.

Super Multitasking

“Adoption of hybrid systems will accelerate when large manufacturers design parts that require internal structures,” says Jim Kosmala, vice president of engineering and technology, Okuma (IMTS booth: 338500). “That will inevitably occur because mechanical engineers understand the strength, weight and performance benefits of additive designs.”

The company’s MU-8000V Laser EX “super multitasking” CNC machine combines five-axis subtractive capabilities with LMD technology for AM, hardening and coating of workpiece blanks. By implementing LMD instead of laser metal fusion (LMF), this machine offers midprocess part inspection and material exchange, coolant use in work envelope, higher deposition rates and three-dimensional fabricating. A 4 kW Trumpf laser can supply power to up to four Laser EX machines.(Trumpf IMTS booth: 236217 and 433037)

More Revenue Streams

HMT has expanded the concept of “done-on-one machine” with product offerings that include metal and polymer AM, melt pool monitoring, inspection and more. Photo Credit: HMT

“Adding hybrid capabilities in-house opens up new revenue streams for mainstream manufacturers and job shops alike by giving them the power to control all steps of the production process,” says Lisa Block, director of global sales and marketing for Hybrid Manufacturing Technologies (HMT, IMTS booth: 432432). “Applications include repair, remanufacturer and feature enhancement. Our patented Ambit deposition heads extend part life cycle by adding layers of high-performance materials such as Inconel and stainless steel.”

HMT has proven its hybrid technology with industry leaders such as Mazak, Romi, Mitsui Seiki, Sugino and Tongtai. Originally, the company debuted the Ambit Flex platform for LMD designed to fit into a standard (CAT 40, HSK, etc.) toolholder for easy integration. In the subsequent years, HMT has released a vast array of product offerings, including but not limited to melt pool monitoring, various modes of inspection and polymer extrusion — all of which can be custom designed to fit any CNC, robot or gantry — further expanding the “done-on-one machine” concept.

To find how hybrid technology can bring more innovation to your manufacturing environment, register for IMTS 2022 and book your hotel now. IMTS 2022 runs Sept. 12-17, at Chicago’s McCormick Place.

Related Content

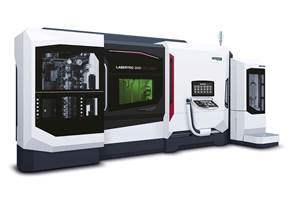

DMG MORI’s Hybrid 3D Printer Offers 5-Axis Simultaneous Machining

DMG MORI’s Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with 5-axis, turn-mill machining in one setup.

Read MoreJuggerBot 3D Awarded $4 Million by Air Force to Develop Large Format Hybrid Additive System

The project focuses on advancing the ability to print a thermoset composite material that can transform the way an aircraft structure is designed, fabricated and sustained for limited-life aircraft.

Read MoreWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More