For Additive Manufacturing, Software Is as Important as the 3D Printer

AM is the process that both requires and realizes the possibilities of manufacturing software. Recently posted articles cover software tools for additive — each article with a companion video.

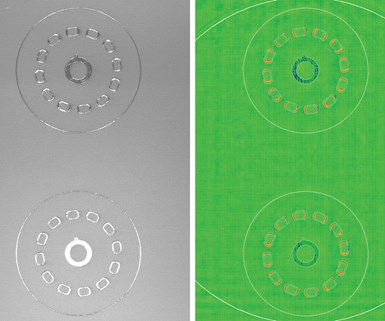

From Velo3D, a photograph of a layer of an AM build and software’s rendering of that same layer based on its interpretation of height mapping data. Read about the uses of this data in one of our recently published articles on how software is advancing AM.

To appreciate the extent to which additive manufacturing (AM) relies on software technology, consider this: I cannot program a 3D printer through manual data input. Or at least I can’t program it this way to do anything useful.

Other manufacturing equipment is not like this. I could have a CNC machine tool perform a face milling cut by entering the few lines of code for this move directly into the control. I could use the machine this way. By contrast, a 3D printer is perhaps the first type of part-making machinery that both assumes and requires the use of 3D modeling software for its input.

Yet despite software’s importance, exploration of additive manufacturing generally focuses on 3D printers and the parts they produce — because there is so much to explore here. For such a young category, additive manufacturing is broad in the extent of all it covers, spanning deposition, fusion and curing processes; polymers, metals, composites and ceramics; and quite possibly every industrial sector making parts. In the physical realm of parts and their applications, there is practically too much to talk about.

But then there is the digital realm.

Shift perspective (the shift is not all that difficult) and it becomes plain that AM is actually a realization of part-making possibilities that digital tools are bringing us. Articles we have recently posted look at additive manufacturing from that perspective, reporting on software tools for additive and focusing on how software is advancing AM.

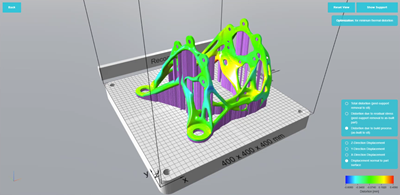

That advance starts with design. Producing complex, optimized geometric forms through additive requires computational technology to arrive at those forms. 3D printing is then the means of completion that can make those forms real. And because 3D printing potentially accomplishes so much in a single print cycle — building the part from the bed up, complete in all its complexity — simulation software is valuable for predicting how the part will form or how the program will behave at the machine. Indeed, the analysis does not end there, because every 3D printing build provides information that might be used to make the design better. AI might even play a role. And then there are the possibilities distinctive to AM. While additive calls for experimentation to find the best parameters for a new build, it is also a process uniquely suited to performing lots of parameter experimentation all at once.

Notably, these software solutions do not necessarily come from “software” companies. Of the six articles linked above, three relate to software technologies developed by companies associated with hardware — that is, makers of additive machines. But in AM more than in any other manufacturing process, hardware and software comprise a full system, so companies providing solutions are naturally innovating in both areas.

These selections on software are not comprehensive; this coverage is just a sampling. In fact, the collection likely is not even finished. The articles linked above all result from a perspective shift of our own, related to how to cover our subject matter. Development of all of these articles began when writers Brent Donaldson, Stephanie Hendrixson and I were each confined at home as a result of the pandemic lockdown. What could we still do to pursue relevant and interesting information to write about? The answer we found involved software demos. Through digital screen sharing, we filmed software providers talking us through their innovations and aspects of their solutions. As a result, every article linked above has a companion video, a useful complement to the article. (Here is the complete playlist.) These selections are just a sampling, as I say, but we might have hit upon a new possibility ourselves — a model for how we will continue to cover software technology in the future.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreLightweight Components: A Paradox When Machining

Today’s computer software can just as easily generate lightweight shapes for subtractive processes as it can for additive ones, but it increases cost and waste to make them.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreTo Scale Additive Manufacturing, Separate Design and Production

Spokbee’s online marketplace is designed to ease the launch and sale of customizable, 3D printed products. Its flexibility comes from cloud-based CAD and a distributed network of service bureaus for production.

Read MoreRead Next

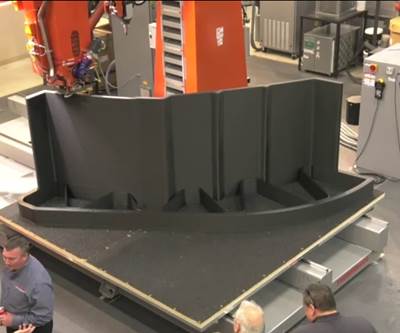

CGTech Extends Simulation to Thermwood LSAM (Includes Video)

Large-scale additive manufacturing platform is the largest 3D printer yet simulated. Watch video for example of how simulation using program G-code catches an error that would otherwise lead to a failed build.

Read MoreA Three-Piece Toolset to Minimize Metal Additive Build Failures (Includes Video)

Three separate software tools from Siemens attempt to control some of the most challenging variables within metal AM: build orientation, distortion and deposition paths. Part of software video series.

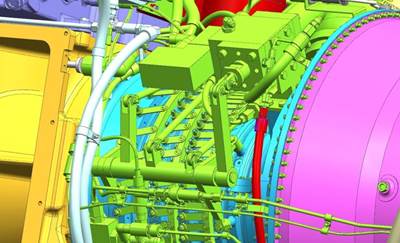

Read MoreTopology Optimization Delivers Nonintuitive Design Features for Legacy Part (Includes Video)

Refurbishing a legacy turbine engine for energy efficiency provided the opportunity to demonstrate topology optimization in concert with metal 3D printing. The design for this torque arm comes from computer simulation insight refined with a human touch.

Read More