CGTech Extends Simulation to Thermwood LSAM (Includes Video)

Large-scale additive manufacturing platform is the largest 3D printer yet simulated. Watch video for example of how simulation using program G-code catches an error that would otherwise lead to a failed build.

This part, which fills the build height of the LSAM machine, took about 16 hours to 3D print. Build failure potentially wastes not just time on a large-format 3D printer, but also a lot of material. Simulation protects against this, as described in the article and video below.

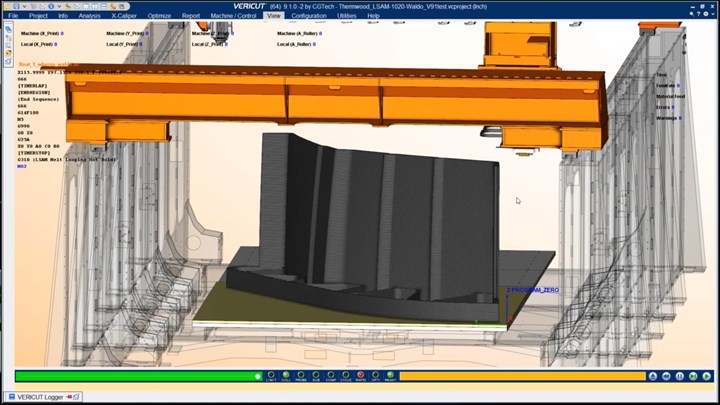

A part made through material deposition on a very large 3D printer potentially requires not just considerable material and machine travels, but also a large program file. To build a part that fills much of the 10 × 20 × 5 foot build volume of just the standard, midsize version of Thermwood’s Large-Scale Additive Manufacturing (LSAM) machine for carbon-fiber-reinforced polymer 3D printing could easily require hundreds of thousands of lines of G-code programming. That is why it’s significant that CGTech has recently introduced simulation capabilities developed in partnership with Thermwood for this line of machines. CGTech is the maker of Vericut software for simulating machining and additive manufacturing processes, and product manager Gene Granata says the LSAM is the largest 3D printer the company has simulated yet.

Size makes the simulation all the more valuable. Vericut is like an “insurance policy,” Granata says. This measure recognizes that, for one reason or another, the posted program might not be perfect. Evaluating the program by giving it a trial run using a digital twin can catch errors in minutes that might compromise the build if discovered during printing, costing wasted material and hours of lost machine time. It can even protect the machine in cases where simulation catches a move that in real life would lead to a crash.

The CGTech simulation executes the same G code the physical machine will. The simulation truly aims to be a digital twin, not just for the machine but also for the process. The software essentially models gravity, too, because additive requirements such as support for overhangs is also part of the simulation.

Importantly, the CGTech simulation executes the posted G-code programming as the machine would. This is why the involvement of the machine maker is required. On the LSAM system, there are G-code commands meaningful only to this machine. “We have over 55 patented features (and over a dozen more pending) that set the LSAM apart from any other large-scale additive system available today,” says Dennis Palmer, Thermwood’s VP of sales. One of those features is an altogether different orientation for printing, the vertical layer printing system. CGTech can simulate the machine’s 3D printing in its various modes, and can also continue into simulating the machining steps that follow on versions of this large 3D printer offering hybrid additive/subtractive capability.

Accurate digital definition of the machine is coupled to digital simulation of the deposition process and its needs. Granata says not just the machine motion is simulated, but also the part resulting from the deposition rate of the material.

I recently spoke to him about the LSAM simulation. He shared an example in which simulation detected a condition of excess overhang. Watch the video:

Related resources:

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreRead Next

Video: How Simulation Assists Directed Energy Deposition

Scrapping an AM part is potentially as costly as scrapping a machined part. Directed energy deposition is an additive process that can benefit from a resource that safeguards machining: simulation software.

Read MoreThermwood’s Vertical Layer Printing Turns AM on Its Side

Vertical Layer Printing (VLP) 3D prints layers perpendicular to the floor, extending Z height to the length of the print bed — as long as 40 feet.

Read MoreVideo: 3 Roles for Simulation in Additive Manufacturing

This conversation with PADT’s Eric Miller explores how simulation and 3D printing work together at three distinct stages in additive manufacturing, for DFAM and beyond.

Read More