Design for Additive Manufacturing (DFAM)

Additive design may mean modifying an existing conventional design for 3D printing purposes, or starting from scratch with a true design for additive manufacturing (DFAM) mindset. Additively manufactured designs often aim for assembly consolidation and lightweighting. They are conducive to biomimicry and complex geometries that optimize negative space and are achieved through generative design or topology optimization. The initial design step considers printing processes, materials, support structures and downstream steps like depowdering and postprocessing.

ESSENTIAL READING

VIEW ALLImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

ListenIn Additive Manufacturing, Is There a Case for Separating Design From Production? AM Radio #25A

Design and 3D printing must inform each other, but keeping them under separate ownership can benefit the designer, the producer and the consumer. More in this podcast episode.

ListenThe 12-Month Transformation of a 3D Printed Product's Design

Rapid product development and continuous improvement are among the advantages of utilizing 3D printing for production. Retraction Footwear offers a literal illustration of the design evolution possible in just one year.

Read MoreGenetic Engineering for Metal: The Promise of Microstructure Control via Additive Manufacturing

“To design the alloy, design the microstructure,” says this Ohio materials science startup. Artificial intelligence is helping to realize a design tool for determining the properties of 3D printed metals.

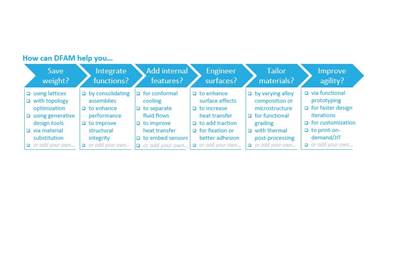

Read MoreFinding Value with Design for Additive Manufacturing

Six questions can help you find value as you apply DFAM.

Read MoreLatest Design News And Updates

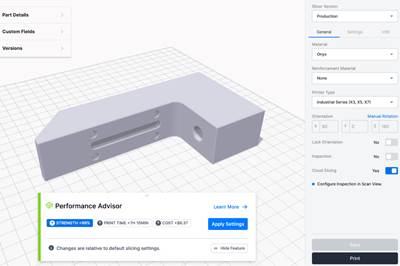

Markforged’s Performance Advisor Accelerates, Simplifies Part Simulation

Markforged’s Performance Advisor technology is use-case independent while being able to fully automate and optimize the performance of a part.

Read MoreWilson Plans to Sell Customizable Airless, 3D Printed Basketball

This limited-edition Wilson Airless Gen1 basketball offering enhanced customization and color options will be available for purchase on Feb. 16.

Read MoreDivergent Technologies Acquires Sigma Additive Solutions’ Software, Intellectual Property

The purchase of Sigma Additive's in-process monitoring software and IP will enhance the efficiency and quality control within the Divergent Adaptive Production System (DAPS) platform.

Read MorePartners Improve Wheelchair Seats, Cushions Using 3D Printed Programmable Foam

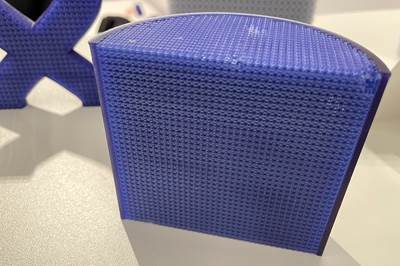

The 3D printed programmable foam is said to enhance orthopedic seats and cushions, offering improved comfort and reliability for users.

Read MoreUpdated nTop Platform Advances AM Design, Simulations

The updated design and simulation solution builds upon nTop's core technologies and introduces new capabilities across four key themes — design, integration, scaling and adoption.

Read MoreHexagon Invests in Divergent’s Autonomous, Sustainable Manufacturing

The Divergent Adaptive Production System (DAPS) is a fully integrated software and hardware solution, creating a complete modular digital factory that combines AI-optimized generative design software, additive manufacturing and automated assembly to build lightweight automotive parts and frames.

Read MoreFeatured Posts

This 3D Printed Part Makes IndyCar Racing Safer: The Cool Parts Show #67

The top frame is a newer addition to Indycar vehicles, but one that has dramatically improved the safety of the sport. We look at the original component and its next generation in this episode of The Cool Parts Show.

WatchIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreIn Armenia, Personalized 3D Printed Shields Improve Fit for Prosthetics

The ongoing conflict in Armenia has left many of its citizens sustaining injuries, especially the loss of limbs. With difficulty in accessing quality health care, many people have poorly fitted prosthetics. The solution lies in 3D modeling and printing customizable prosthetic case covers enabling better healing outcomes and comfort for patients.

Read MoreFeatured Media

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

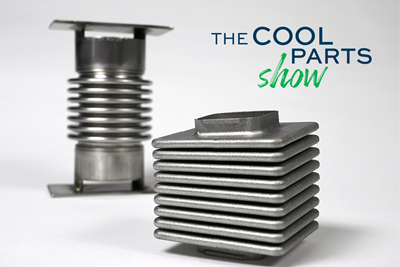

WatchFlexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

WatchA Look at Lattice: The Cool Parts Show All Access

Lattice structures are great, but they have to end somewhere. When designing head padding made from lattices, how do you design the surfaces where the pads adhere to the helmet? Marek Moffet, chief technical officer for General Lattice, talks about that here.

WatchFAQ: Design

What do you use to create a design for 3D printing or additive manufacturing?

Ultimately, 3D printing designs are created using CAD software and then prepared for 3D printing with a slicer that divides the model into layers. This software allows a designer to create 2D and 3D designs.

What is topology optimization?

Topology optimization mathematically configures a design and material distribution to most efficiently meet predetermined parameters such as size and strength.

“So what topological optimization is saying is I've got these loads and I'm going to remove material in order to minimize the amount of material that I have. And it's actually a fairly simple process of putting a load on, looking where the stresses are, where there's no stresses, reduce the stiffness and the density, and keep doing that until you get holes and your part is going to work.”

–Eric Miller, of Phoenix Analysis & Design Technologies, discussing the difference between topology optimization and generative design with Additive Manufacturing Media’s Stephanie Hendrixson.

What should designers remember when creating negative space in a 3D printed part?

When designers include channels in their parts, they often forget that these features don’t have to be bound to the shape of a simple round hole. With 3D printing, holes and channels can be any shape that provides proper support for the build.

Why are interior radii important when designing for 3D printing?

Parts that look sharp shouldn’t necessarily have sharp edges. In fact, with 3D printed parts, it’s better to look smooth. Whenever possible, use interior radii for edges and corners. That smooth contour not only has a great look, but it has the benefit of relieving the stresses that build up during the printing process.

What is lightweighting in additive manufacturing?

Lightweighting is producing a part that weighs less than a similar part made through another manufacturing process. Additive manufacturing’s ability to provide complex geometries with internal passages often results in a lighter part compared to a conventionally manufactured part. More negative space means less weight.

This microturbine is an example of a lightweighting success.

What are complex geometries in additive manufacturing?

Complex geometries are shapes and designs that are intricate or could be difficult to create with conventional manufacturing options. For example, a part that requires interior coolant delivery will need channels that not only deliver fluid, but also allow for the fluid to exit the part. With conventional manufacturing, this could demand the production of multiple parts that must then be assembled or machined. However, additive manufacturing can produce a single part with built-in channels that can be in almost any shape, not just round holes.

An example of a complex geometry made possible only by additive manufacturing is this heat exchanger that uses gyroids for better cooling.