Wilson Plans to Sell Customizable Airless, 3D Printed Basketball

This limited-edition Wilson Airless Gen1 basketball offering enhanced customization and color options will be available for purchase on Feb. 16.

Share

Read Next

This limited-edition Wilson Airless Gen1 basketball offering enhanced customization and color options will be available for purchase on Feb. 16.

Wilson Sporting Goods Co. says it will begin selling the Wilson Airless Gen1TM — an innovative, first-of-its-kind 3D printed basketball that never needs to be inflated. Building off the success of the Airless Prototype debut last year, the limited-edition Wilson Airless Gen1 basketball will be available for purchase on Feb. 16.

“We were overwhelmed by the excitement from our Airless Prototype, and we knew it was time to bring this rare, first-of-its kind innovation to the world,” says Kevin Murphy, general manager, Team Sports at Wilson. “Wilson has gone where no brand has gone before with the release of the Airless Gen1 basketball, further inspiring the next generation of sports innovation.”

The Wilson Airless Gen1 has similar functionality to the prototype. However, over the last year, the Wilson Labs team has taken steps to increase performance and streamline the manufacturing process. The basketball nearly fits the performance specifications of a regulation basketball, including its weight, size and rebound (bounce). While the Wilson Airless Gen1 is crafted for play, it is a technology-infused product meant to create and inspire a new community of innovation and basketball enthusiasts.

The main updates to the Wilson Airless Gen1 include:

- Improved functionality — Upgraded lattice design for more consistent performance and bounce. The ball still includes the same see-through lattice with eight panel-like “lobes.”

- Streamlined manufacturing — Holes integrated within the channels help speed up the manufacturing process, making it faster to create each ball. The basketball remains airless and does not to be inflated.

- Enhanced customization — Each ball will have a built-in label for customization and will feature the exact, limited number in which it was produced.

- Color variety — In addition to the recognizable jet-black colorway of the prototype, the Airless Gen1 will also be available in brown and natural white.

The Wilson Labs team leveraged the same game-changing process to create the Wilson Gen1 Airless basketball with key partners. General Lattice provided computational design services for elevated performance optimization, DyeMansion provided color and finishing solutions, EOS provided technical oversight and a roadmap for mass production, while SNL Creative was the primary manufacturing hub for this first launch.

Limited units of the Wilson Airless Gen1 will be available exclusively on Wilson.com beginning Friday, Feb. 16 for $2,500. Fans can also experience the product at Wilson’s on-site activation at NBA Crossover in Indianapolis Feb. 16-18.

Wilson knows a thing or two about basketball. Wilson is the supplier of official game basketballs for the National Basketball Association (NBA), the Women's National Basketball Association (WNBA), National Collegiate Athletic Association (NCAA) for March Madness and the Final Four, Basketball Champions League (BCL), Basketball Africa League (BAL) and FIBA 3x3.

The companies first announced the airless prototype in March 2023. General Lattice’s enterprise solutions team worked with Wilson to bring its concept to life by streamlining the design and iteration process through the use of its computational design tools and workflows.

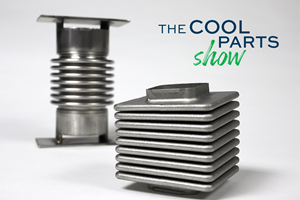

Watch to learn more about the promise of 3D printed lattices in this episode of The Cool Parts Show.

Related Content

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreFlexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.

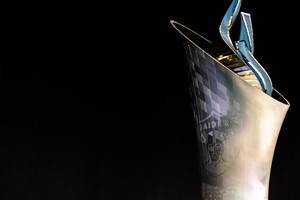

Read MoreThe World’s Tallest Freestanding 3D Printed Structure

Dimensional Innovations paired additive and subtractive manufacturing to create a monument for the NFL’s Las Vegas Raiders new stadium. The “never been done before” project resulted in the world’s tallest freestanding 3D printed structure.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More