Markforged’s Performance Advisor Accelerates, Simplifies Part Simulation

Markforged’s Performance Advisor technology is use-case independent while being able to fully automate and optimize the performance of a part.

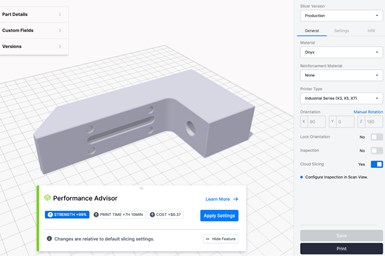

Performance Advisor offers a physics-based analysis method that addresses the challenge of doing structural analysis without a use case. Source: Markforged

Markforged has added a Performance Advisor feature to its Eiger software, giving users a faster, simpler way to automatically simulate parts to make them stronger. The feature enables users to create stronger, more robust parts while maintaining a balance with material and print time efficiency — automatically and without any user input. The company says the feature builds on Markforged’s Simulation tool to take the guesswork out of 3D printing.

Simulation usually requires a known use case — how the part will be loaded and how it interacts with other objects when it is in service — which is often unknown. To address this challenge, Markforged’s technology is use-case independent while being able to fully automate and optimize the performance of a part.

Unlike traditional tools that might need specialized expertise and time-consuming analysis, this technology is powered by machine learning and operates with the click of a button. It’s a method of analyzing part performance to recommend print settings that result in a strong part that is manufactured efficiently — a part that balances strength improvements with minimal increases in cost and print time

The company says that manufacturers who don’t know CAD can use it, and it reduces the stress of having to be a structural analyst or go through trial-and-error. Customers can use the Simulation tool to explore how changes in print settings impact part performance, and optimize for cost and print time.

The process is fully automated. No user input is needed to generate the results. After users save a part in Eiger, Performance Advisor will automatically analyze the part and recommend print settings that, relative to the default settings, improve the strength while keeping material cost and print time low. Users can then decide if the performance improvement is worth the added cost and print time. Users can apply the recommended settings with one-click or ignore them and proceed with the Eiger workflow.

This physics-based analysis method addresses the challenge of doing structural analysis without a use case. In lieu of defining a use case, the shapes in which a part naturally vibrates (the eigenmodes) of the part geometry are used to explore the impact of print settings on part performance.

Computing the lowest energy eigenmode is the first step. The second step is to run a machine learning driven optimization procedure that scores print settings using three variables — strength, material cost and print time. Print settings that score high in strength and low in cost and print time are considered optimal. These configurations are what Performance Advisor aims to recommend.

The company says the capabilities of Performance Advisor will grow over time. For the initial release, important limitations are:

- Onyx is the only supported material.

- Wall Layers and Roof and Floor Layers are the only print settings adjusted.

- The Fill Pattern is Triangular and the default Fill Density is held constant.

- Performance Advisor may not be able to analyze parts with extremely complex STL meshes.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreTo Scale Additive Manufacturing, Separate Design and Production

Spokbee’s online marketplace is designed to ease the launch and sale of customizable, 3D printed products. Its flexibility comes from cloud-based CAD and a distributed network of service bureaus for production.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More