What Is Implicit Modeling?

Implicit modeling is a way of representing a geometric shape using equations. Data about the geometry is stored in a signed distance field, essentially a grid; each point of data in this grid indicates how far that point is from a boundary. Rather than a literal representation of the surfaces of a shape, implicit modeling is more of a “recipe” for the geometry.

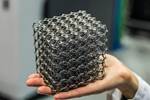

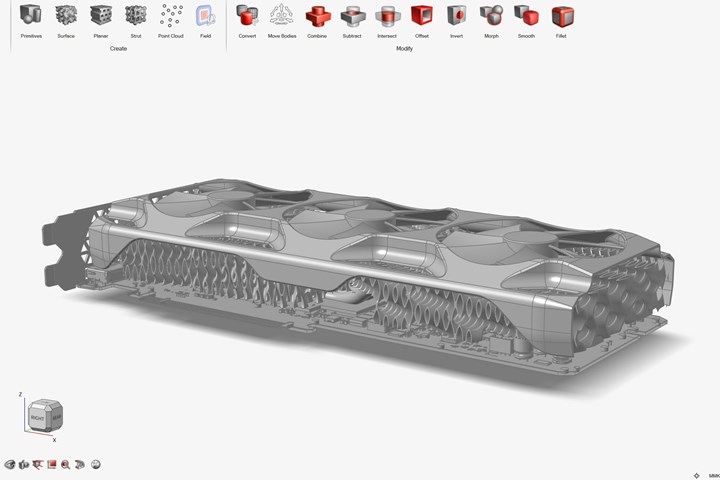

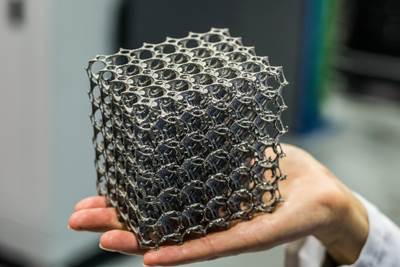

Parts like this (shown in Altair Inspire 2023) that include lattices and many surfaces can be more easily designed and modified through implicit modeling tools. Source: Altair

How Does Implicit Modeling Differ from Explicit Modeling?

In explicit modeling methods used by most CAD systems, shapes are modeled by explicitly describing their boundaries — in other words, the vertices, edges and faces that define the surface of the shape. Geometries are typically represented either with boundary representation (B-rep) solid models or a triangle mesh.

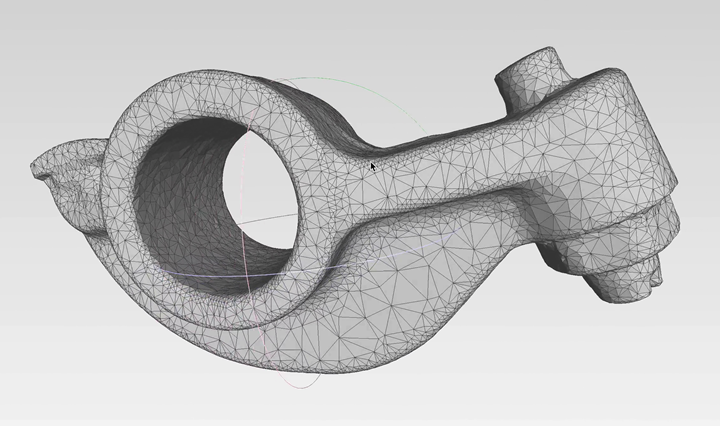

Explicit modeling uses strategies such as boundary representation (B-rep) model or triangle meshes, as shown here, to directly represent a part’s surfaces. Source: Metafold

For many parts, explicit surface modeling poses no particular challenge. However, for the complex parts that additive manufacturing can produce, software based on explicit modeling can get bogged down in processing. If there are many surfaces to represent, this translates into large file sizes and difficulty in making changes as well as in saving and sharing files.

What Are the Benefits of Implicit Modeling?

The implicit modeling capabilities within nTop were used to lightweight this Aerojet Rocketdyne injector body. By shelling out the structure and filling it with a thin lattice structure, designers were able to reduce the quad injector’s mass by half — and do it quickly. Source: Velo3D

Compared to explicit modeling methods, implicit modeling can lead to faster processing of design changes and smaller file sizes. Because implicit modeling is based on equations rather than discrete data, the strategy makes it easy to scale up designs or make modifications without slowing down the software.

Implicit modeling may allow designers to overcome previous constraints imposed by CAD software, enabling faster processing of complex structures such as gyroid lattices, as well as the use of new kinds of shapes. This modeling technique can more easily enable opportunities such as metamaterials and material property gradients based on geometry.

What Are the Drawbacks of Implicit Modeling?

When used to recreate objects from the physical world, implicit modeling may be less accurate than explicit modeling. The model’s outcome depends on the inputs and skill of the designer.

Implicit modeling is perhaps better suited to developing new designs, where support for design complexity and flexibility in iteration is more important.

How Does Implicit Modeling Help Additive Manufacturing?

While explicit modeling is well-suited to subtractive operations based on surfaces such as CNC machining, implicit modeling can be a more efficient choice for representing the complex infill structures and other features that additive manufacturing makes possible. Implicit modeling is especially effective for designing parts that include many surfaces, such as heat exchangers, filters and bioreactors.

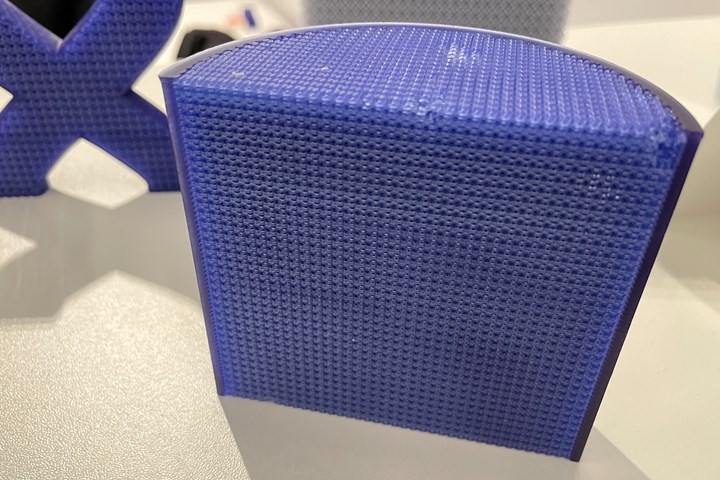

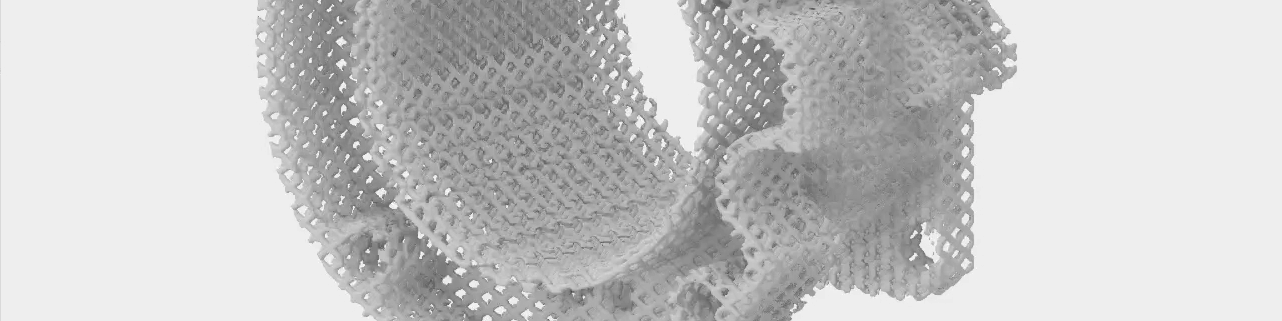

Surface-heavy geometries like this bioreactor can be difficult to model explicitly, especially as the physical size of the part (and therefore the size of its file) scales. Using implicit modeling tools like the Metafold software that designed this part can make file creation, modification, saving and sharing much more efficient.

Implicit modeling avoids the file size challenges of explicit modeling by avoiding the need to literally represent every surface on a part. Its method of using equations to describe geometry, rather than B-rep or mesh models, makes it faster and easier to execute design files, and results in smaller, more portable file sizes. In some cases switching from explicit to implicit modeling can result in time savings on the scale of days to alter or save a design file.

Can Implicit Models Be 3D Printed?

nTop and EOS have partnered to create an Implicit File format that can reduce file size as well as generation and load time. Siemens Energy designed this heat exchanger to demonstrate the capability; the design was exported to the file type in just seconds, required less than 1 MB storage, and was directly printed on an EOS M290. Source: EOS

In many cases designs that have been developed with implicit modeling tools are exported as STL files to create explicit representations for 3D printing. It is also possible to export sliced models including stacks of images for digital light processing (DLP) and other light-based 3D printing processes, as well as hatch patterns.

While exporting implicit models to explicit formats is common, some tools also make it possible to print the implicit model without such conversion. Some platforms can even stream implicitly modeled geometry directly to the 3D printer, providing the representation data piece by piece, just as it is needed for printing. With this method, the implicit model is not converted into explicit data, but directly translated into the physical part.

Can Implicit Modeling Be Combined with Other Strategies?

Yes! “Hybrid modeling” that combines implicit strategies with explicit modeling can be useful for parts that include both simple and complex surfaces. In this example from Oqton, B-rep is used to model the intake of a heat exchanger, while implicit modeling was applied to the interior lattices.

What Software Uses Implicit Modeling?

Design programs and software including implicit modeling capability include Altair Inspire, Autodesk Fusion 360, Metafold (platform and API), nTop, Oqton 3DXpert, Rhino through various Grasshopper plugins, and Siemens NX.

What Other Ways Can Implicit Modeling Be Used?

Outside of manufacturing, implicit modeling is also being used to produce visual effects; to represent natural features in geology and mining; to model organs and blood vessels in medicine; and in quantum mechanics research, among other applications.

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreAM 101: What is Ultrasonic Additive Manufacturing?

Going from additive to subtractive can be simple with Ultrasonic Additive Manufacturing (UAM). What is it and how does it work? Learn the basics in this 101 post.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreRead Next

What Are the Unexplored Frontiers of AM Lattice Fabrication?

A recent literature review discovered that most research into AM lattices is limited to PBF in metal and extrusion in polymer — and that experiments could be underestimating in-service lattice mechanical behavior.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read More

.jpg;width=70;height=70;mode=crop)