What Does AM Want? Here Are 4 Aims (Maybe 5) That Additive Manufacturing Is Driving Toward

Certain freedoms and contributing factors allow additive manufacturing to realize its full promise for production.

Creatures have habitats. People have homes, the places where they belong. Take a person or an animal out of these settings where they want to be, and they still might live, but they won’t thrive. And this basic truth offers an analogy for one of the most important points we’ve come to understand about additive manufacturing in the first decade of its advance as a part-production technology.

Namely, additive too has a proper habitat of sorts. It has a home. It can’t be dropped into an existing production facility or supply chain that was made for another process. If it is, it will succeed at making parts in this setting, but it won’t realize its promise. Additive manufacturing “wants” certain conditions to be present in the context it operates in. It drives toward certain changes to the manufacturing enterprise that embraces this mode of production. And over time, the successes with AM for production have shown what AM seeks in order to have this success. What does additive want? At least this much is now clear:

1. AM Wants to Consolidate

Using additive manufacturing effectively rarely involves just one part that was previously made through a different operation. The optimal use instead more often involves what previously was a subassembly — an entire collection of parts, perhaps from various suppliers, all combined into what is now one single intricate piece. AM wants to consolidate components.

And then it wants to consolidate people. Or more accurately, it wants to consolidate disciplines by bringing people from different departments together. In AM for a metal part, for example, design has to anticipate the needs of machining and quality, and machining and quality will encounter challenges that can be addressed with additive’s freedom of design. All these factors continue to evolve as the geometry and process of the part both advance, meaning the stakeholders cannot be stops in a linear sequence but instead have to interact with one another all through the additive part’s development.

2. AM Wants to Adapt

With additive, small shortcomings in the performance of the product or its production steps are opportunities for further design change in search of improvement. The design of an additive part is fluid enough that AM achieves next-level transformation in part through the accumulation of many design refinements. The chance for a responsive, iterative design is part of the freedom additive both offers and requires in order to do its best. For products where the final form need not be qualified and locked in, even going to market need not be the end of the change. Additive offers the chance to adapt further by making refinement based on how the product is received and applied by its users.

3. AM Wants to Change the Material

Today’s metal part does not have to be metal tomorrow. A 3D printed component made of polymer composite might perform the function instead. Ceramic and metal matrix composites potentially become more accessible through 3D printing as well. Our assumptions today about the materials different parts ought to be are based on the possibilities of established manufacturing processes. Demanding additive manufacturing deliver a part in the same material as the part it is replacing limits AM’s promise. What additive offers instead is the chance to realize the performance and properties required using some different material that delivers other advantages as well.

4. AM Wants to Lead

While additive won’t be the process making high-quantity parts at the fastest rate, it will be the first process off the blocks and the one with the shortest lead time. Additive wants to lead by serving a new need or market demand at once with the production that 3D printing can deliver, while more traditional processes are still being tooled up or are waiting to be called upon.

Increasingly, additive also wants to lead in engineers’ thinking. Younger engineers expect 3D printing, because it is the part-making capability they have the most interaction with during their education. The direct connection from desktop 3D printers to additive manufacturing shifts additive from being less a novel choice for production engineers to more of the starting point for their consideration.

An additive part with complex internal geometry seen at Collins Aerospace. Protecting the design secrets inside a component like this is part of the reason Collins has expanded its own internal AM production capacity.

This list of wants is still developing. The ideal habitat for AM is still being charted and explored. One possible addition to this list is on my mind with a recent article. That is, could it also be said that AM wants to insource? I think so; additive manufacturing wants designers and producers in close and continual interaction, and Collins Aerospace’s investment in AM in part to protect engineering advantages hints at how the IP of additive parts and processes argues for production in-house. But then, OEMs generally want to outsource, and even Collins makes clear it still wants AM suppliers. Precisely where AM should best operate in the supply chain (and the answer might be different for different products and sectors) will be another aspect of additive finding its home.

Related Content

Video: 3D Printing Paired with Plastics Joining

Conventional 3D printing wisdom is to combine as many components as possible into one 3D printed piece. Plastics joining technology expert Extol illustrates the benefits that come from printing in many pieces instead.

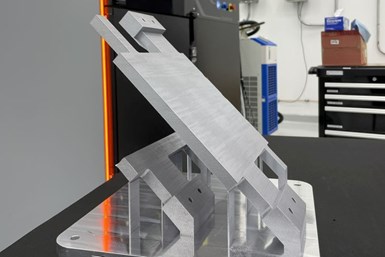

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreFlexing Thermoset Polymers Into Production 3D Printing

Chromatic 3D Materials develops tough and flexible thermosetting urethanes for additive manufacturing. The resin formulation is only part of the path to scale.

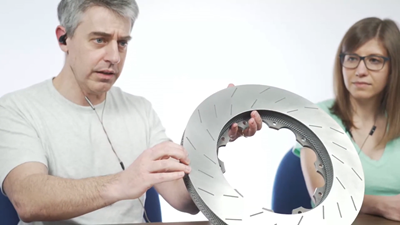

Read MoreVariable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

Read MoreRead Next

Material Innovation Is a Powerful Freedom of AM: Here Are Examples

Possibilities that were speculative a few years ago are coming true today. Applications of metal matrix composite provide an example. Recent articles explore the ongoing advance of 3D printed materials.

Read MoreHow Bridge Production Is Bringing New Possibilities: AM Radio #14A

Additive manufacturing makes bridge production a more natural factor in the production strategy overall. This has important implications for product development and even what products are possible.

Read MoreThis 3D Printed Turbine Replaced 61 Parts With 1: Here Is What That Means

Additive manufacturing makes possible a radical microturbine that increases power-to-weight ratio, reduces cost and extends time between overhaul.

Read More