The Exoplanet Climate Infrared Telescope (EXCITE) is a NASA mission that will use a large balloon to carry a telescope to the edge of space above Antarctica, where it will measure the atmospheric compositions of planets orbiting other stars. The telescope assembly needs brackets delivering high stiffness with low mass, and the engineering team at NASA's Goddard Space Flight Center is using a combination of artificial intelligence and additive manufacturing to obtain this hardware. The so-called “evolved structures” realized through generative design are so geometrically complex that metal 3D printing via laser powder bed fusion offers a practical way to produce them — and in the case of a large titanium bracket, offers the only cost-effective method. The Cool Parts Show visits the Goddard Space Flight Center for this episode on AM and AI enabling the exploration of alien worlds. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- EXCITE mission overview and status, and an early paper describing the mission

- Other AM parts resulting from generative design

- AM Radio podcast episode on the connection between AM and AI

Transcript

00:00:00:05 - 00:00:00:18

Pete Zelinski

I'm Pete.

00:00:01:02 - 00:00:13:22

Stephanie Hendrixson

I'm Stephanie. And this is The Cool Parts Show our show all about interesting, unusual, innovative, 3D printed parts. On today's episode, we're going to be talking about space exploration, planets outside of our solar system and artificial intelligence.

00:00:14:12 - 00:00:25:13

Pete Zelinski

We're also going to be talking about lightweighting assembly consolidation and more efficient design. Brackets for NASA's EXCITE mission, on this episode of The Cool Parts Show.

00:00:31:12 - 00:00:45:00

Stephanie Hendrixson

This episode of The Cool Parts Show is brought to you by Carpenter Additive. The company's PowderLife solution is a combination of hardware and software technologies designed to help AM users manage their metal powders. Stay tuned after the episode for more on how the system works.

00:00:45:15 - 00:00:47:02

Pete Zelinski

Welcome to The Cool Parts Show.

00:00:47:12 - 00:01:04:20

Stephanie Hendrixson

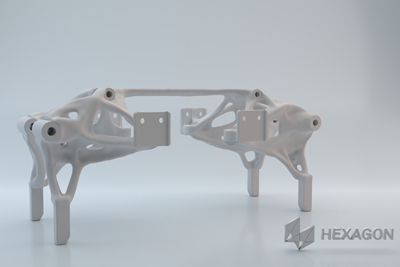

Thanks for joining us. And if you like what you see, help us out by hitting that subscribe button, you'll get notified about all of our new episodes. Today on the show we're going to be talking about these brackets for NASA's EXCITE mission. This is going to send a large balloon up into Earth's atmosphere to study exoplanets. The smaller bracket that we have here is called the tip or tilt bracket.

00:01:05:01 - 00:01:07:11

Stephanie Hendrixson

And the larger one is referred to as the transfer box.

00:01:08:00 - 00:01:36:20

Pete Zelinski

So these brackets. One is aluminum, one is titanium. They're made through laser powder bed fusion. They are components for NASA's EXCITE mission planned for 2025. EXCITE, Exoplanet Climate Infrared Telescope. So basically a giant balloon size of a football field is going to carry a telescope all the way through Earth's atmosphere to the very edge of the atmosphere, the edge of space.

00:01:37:01 - 00:02:07:16

Pete Zelinski

That telescope is going to orbit the South Pole long enough to stare at distant stars and see some of their planets and measure the contents of the atmosphere of some of those planets. Up until the point when the telescope system parachutes back down to earth. So these brackets have to do a lot. They've got to be stiff enough to hold vital components of the telescope system in just the right place as the entire system ascends all the way through the atmosphere.

00:02:07:16 - 00:02:32:11

Pete Zelinski

And they have to be light enough that the system in total can have small enough mass that a balloon can lift it all the way up there. And then they have to be strong enough to survive, the violent jerk of this parachute deploying as it falls back to Earth. NASA engineers, to devise brackets that could satisfy all of these different engineering requirements,

00:02:32:13 - 00:02:34:18

Pete Zelinski

they turned to artificial intelligence.

00:02:35:03 - 00:02:54:05

Stephanie Hendrixson

Yeah. So both of these brackets were created with generative design, applying artificial intelligence to quickly iterate and get through lots of different variations and arrive at the best possible design. They were specifically created using Autodesk Fusion 360 and they were optimized for all of those characteristics that you mentioned earlier. So lightweight, stiffness, we'll talk more about the requirements later.

00:02:54:14 - 00:03:19:08

Stephanie Hendrixson

So NASA is really interested in the possibilities of generative design, not only for that optimization but also for the speed that it allows. So if you think about it, a mission like EXCITE or lots of other NASA missions, there's going to be situations where you're making just one of a particular bracket or part. And so being able to arrive at the best possible design very quickly is extremely advantageous for the teams at NASA that are tasked with making the stuff that scientists need.

00:03:19:19 - 00:03:31:04

Stephanie Hendrixson

For this episode, we actually got to go to Greenbelt, Maryland. We got to meet one of these people at the Goddard Space Flight Center. This is Ryan McClelland. He is a research engineer with NASA's Instruments Systems and Technology Division.

00:03:31:22 - 00:03:50:06

Ryan McClelland

So I have a really great job. I think it really fits me perfectly. It's called research engineering. So my job is to sort of connect what the scientists need with what engineers can do. So coming up with things that's going to enable those future instruments to take measurements that have never taken before of the earth and space. Right.

00:03:50:06 - 00:04:10:07

Ryan McClelland

The EXCITE Balloon mission is really unique, it’s going to launch from Antarctica and the balloons are massive. They're like the size of a football stadium and it's going to take it up to over 99% of Earth's atmosphere. And from there, it actually is going to look at the atmospheres of exoplanets, which is sort of amazing thing to do just from, you know, not even all the way into space.

00:04:10:17 - 00:04:26:20

Ryan McClelland

And one of the really cool things about being in Antarctica is that it can just stare for a long time at the stars. So if you had a low earth orbiting satellite, you know, the Earth would be hiding a lot of the stars. As you go around. But since you're at the pole, you can just, you know, stare for a long period of time.

00:04:26:20 - 00:04:39:02

Ryan McClelland

And what you're looking at is hot Jupiter size exoplanets transiting other stars and you can do what's called spectroscopy, where you're actually learning about the atmosphere of those exoplanets, which is pretty wild.

00:04:40:02 - 00:05:09:15

Pete Zelinski

You said generative design. Ryan and his team use this different term, evolved structures, to describe the way that the generative design actually works. The A.I. is cycling through one solution after another. It's iterating rapidly, lots of trial and error, iterating through tens of thousands of different possibilities to find the geometric form that best satisfies all the requirements it was given.

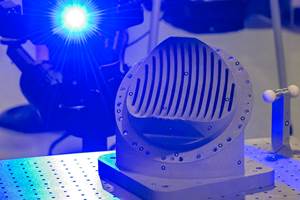

00:05:10:05 - 00:05:47:01

Pete Zelinski

So this bracket, it's purpose is to hold a mirror at a precise angle. And this bracket, it holds the cryosat, basically this cryogenic chamber that maintains the precise low temperature needed for the spectroscopy detector. Both of these brackets are ready to go and they will do the job well. But it's worth saying this is a work in progress and NASA is still experimenting with different sets of boundary conditions, different sets of requirements, aiming at getting even more sophisticated additive manufactured brackets.

00:05:48:01 - 00:06:06:10

Ryan McClelland

Right. So evolved structures are these kind of weird alien bone looking things you see here, and they are essentially structures that are made using what we've called the evolved structures process. So that evolved structures process, you can think of it, if you know about AI, you can think of it as prompt engineering for structures AI.

00:06:06:19 - 00:06:27:07

Ryan McClelland

So you have to tell the computer what you want it to do. So NASA is a lot different than like a car company or a bicycle company that might sort of make the same kind of components over and over again. At any time NASA has thousands of unique structures in development, and most of our costs are not driven by manufacturing, but non-recurring engineering.

00:06:27:16 - 00:06:33:02

Ryan McClelland

So when we have unique structures to be able to develop them faster is a big win for us.

00:06:33:16 - 00:06:54:21

Stephanie Hendrixson

So the evolved structures process is kind of doing two things at once. On the one hand, it's dramatically speeding up the time it takes to develop a particular part, but it's also allowing for the optimization for those different variables. So whether that is to support a particular load, to survive a particular impact, whatever it might be, it's helping NASA engineers achieve the best structure as quickly as possible.

00:06:55:07 - 00:07:30:23

Pete Zelinski

And NASA represents an extreme version of this need. But it's a need that maybe any engineer would recognize. Before a new product can be introduced, before a new part can be developed, that product or that part has to be designed. The design is part of the effort. Part of the investment. Generative design is allowing not just faster design, but also design outcomes, designed forms that a human designer wouldn't be able to conceive of or even know to produce.

00:07:31:11 - 00:07:52:12

Ryan McClelland

This amounts to the back of a telescope. This would be the back to the telescope. And then this mass here represents the overhanging mass of the mirror assembly that attaches to it. So taking on that problem, a human designs something like this. So it's basically, you know, sketching in flat planes and then extruding. It's all very human looking because it's very planar.

00:07:52:22 - 00:08:21:10

Ryan McClelland

But that limitation of being planar really limits the performance. So these brackets take the same problem and they make it much lighter, stiffer and stronger all at the same time because they can think about novel structures like this that really respond well to what's happening. So in this case, you can imagine that this overhanging mass wants to twist and the human designer didn't really quite design for that load case.

00:08:21:11 - 00:08:42:09

Ryan McClelland

You can see this is probably going to be great for twisting, whereas this has this sort of crisscross pattern that prevents this part from twisting. And it's something that a human not only wouldn't necessarily think of, but couldn't even design in CAD if they had thought of it, because it's just too complex of a surface. Modeling the base geometry of just these simple shapes probably only took about 30 minutes.

00:08:42:22 - 00:09:00:09

Ryan McClelland

And then an important part is like understanding what the requirements are, but the requirements for the balloon loads are pretty well known and the requirements for it being lightweight and having a high frequency were well known. So you encode those into the generative design tool and then that takes maybe a half hour and then it takes about an hour to run.

00:09:00:15 - 00:09:18:16

Ryan McClelland

And in an hour it actually can make, you know, many different variations for you to choose from. And then the human designer can go back, make sure there weren’t requirements missed and make sure it looks right. You sort of have to still apply, you know, human intuition to it just to make sure you didn't miss something or the software didn't go off the rails.

00:09:19:05 - 00:09:26:12

Ryan McClelland

And then the evolve structures process will build the rest of this in a way that satisfies your requirements and is readily manufacturable.

00:09:27:06 - 00:09:48:08

Stephanie Hendrixson

So along with meeting the design requirements, that manufacturability piece is really important. A human designer who's thinking about machining is going to design something like this, something that's suitable to be made on a CNC machine tool. But as we've seen in other episodes of The Cool Parts Show, generative design pairs really well with additive manufacturing. It allows you to get some of those more optimized geometries.

00:09:48:13 - 00:09:58:03

Stephanie Hendrixson

So things like the kind of hollow structures that we see on this bracket, reducing weight from the geometry without adding a lot of extra waste or time to the manufacturing process.

00:09:58:20 - 00:10:30:18

Pete Zelinski

Generative design pairs well with additive manufacturing. I like the way that you said that. Generative design ends up creating these very intricate, very counterintuitive organic forms, and 3D printing is all set to go to produce complex, intricate, counterintuitive organic forms. But it's worth saying, NASA wasn't interested in making 3D printed brackets. NASA was interested in getting the best brackets they possibly could.

00:10:31:20 - 00:10:57:21

Pete Zelinski

Here is a version of this bracket produced through CNC Machining. CNC Machining, five axis machining specifically, is another option for getting very complex, intricate forms. So what the NASA team did in the case of this version of the bracket is they specified within generative design, one of the requirements is the resulting form had to be machineable. Meaning

00:10:57:21 - 00:11:22:13

Pete Zelinski

every part of the form had to be reachable by the cutting tool in a five axis machining center. That took away some geometric freedom. So for example, like sort of the cavernous recesses inside this part, it's not really possible on this machined version. So this one's a little heavier, but these are parts made of aluminum that is an easy material to machine.

00:11:22:22 - 00:11:51:23

Pete Zelinski

It's a relatively compact part, producing this form through machining was less expensive, significantly so than this version of the bracket. And that's not insignificant. With this bracket it was a different story. This is made of titanium. And so to machine this form the starting point would be a block of titanium with this span and these dimensions.

00:11:52:10 - 00:12:12:02

Pete Zelinski

So that would be a lot of material waste to machine this form out of that material and a lot of effort and energy spent on machining a hard metal. So that made machining cost prohibitive. In this case, this version of the bracket pretty much had to be made through 3D printing.

00:12:12:19 - 00:12:30:20

Stephanie Hendrixson

So Ryan's team started out applying this evolved structures philosophy to this tilt bracket because it's a pretty small part and it can fit into the build envelope of most available 3D printers. But when they got the chance to work on this transfer box, obviously it's quite a bit larger. It also has its own set of requirements to meet.

00:12:31:09 - 00:12:50:22

Ryan McClelland

Right. So the transfer box basically holds the cryostat that has the cold detector in it. So the detector is down around 50 kelvin, very cold and it's held off the back, cantilevered off the back of the telescope. So when you have a large mass like that, it's 50 kilograms cantilevered off the back of something and you need to be stiff, over 100 hertz.

00:12:50:22 - 00:13:14:03

Ryan McClelland

It's very hard to come up with a structure like that, just using manual design and thinking in this planar fashion. And it's also hard to think in the planar fashion because the back of the telescope is round, about the size of this and round. So the transfer box, when you see it, reaches out to optimal places on the telescope so that it can support that mass as rigidly as possible.

00:13:14:08 - 00:13:35:21

Ryan McClelland

So I sort of said in the tool in the first pass, you can mount anywhere on the back of this telescope and you have to hold this large mass cantilevered off. And then I followed the guidance of it that it wanted to put members in certain places and then went back and specified, you know, redundant bolt patterns at those places and then reran it to get it to optimize to those locations.

00:13:36:05 - 00:14:01:18

Ryan McClelland

So a lot of times our designs end up being stiffness driven. And this is the case with this structure. The strength is like a factor of like ten stronger than it needs to be, but it's the stiffness that we really need out of it. And that is something that this particular technology, you know, the underlying technology of this is level set topology optimization sort of at the very base layer what's going on. And that uses something called compliance minimization.

00:14:01:18 - 00:14:06:07

Ryan McClelland

So basically at the mass that you're choosing, it gives you the stiffest possible structure.

00:14:06:20 - 00:14:30:07

Pete Zelinski

The 3D printed brackets were both made by 3D Systems. This big titanium bracket actually was 3D printed in Belgium. That is where 3D Systems had open capacity on a machine big enough to accommodate this part. The parts were shipped to NASA Goddard, where they were subjected to a lot of tests to make sure they could do the job, basically to confirm that the AI got it right.

00:14:30:18 - 00:14:49:21

Ryan McClelland

So these parts were tested first in vibration. We very typically do vibration tests on things that go into space to represent the launch loads. And in this case it's actually going to be going up on a balloon, which is much gentler. And the main load is what's called chute shock, because we're actually going to get this back and potentially fly it more than once.

00:14:50:09 - 00:15:11:15

Ryan McClelland

So that chute shock load, we simulated that by shaking it, sort of like slamming it back and forth on the vibration table. And then we also did what's called a science sweep where we shake it on the vibration table and you see where the acceleration response peaks. So you know what its natural frequencies are. So we did vibration tests on these parts and then we also did a pull test to failure.

00:15:11:21 - 00:15:45:21

Ryan McClelland

So it's always great to actually break things and really understand when it is that they fail. So you can see that the AlSi10Mg part actually snapped here at the foot where the stress concentration is, and it's exactly the same place that from finite element analysis you would expect it to break. And then the the A6061-RAM2 part you can see cracked here and then the CNC part you can see that the hole, it's pretty subtle but the whole stretched and actually end up breaking the bolt.

00:15:46:13 - 00:15:58:01

Ryan McClelland

So the transfer box really sees the same kind of load cases as this. So the testing was identical, but with much more mass and much larger requirement for the machine shaking it.

00:15:58:12 - 00:16:22:14

Stephanie Hendrixson

So as we talked about earlier in the episode, the time that it takes for NASA to put together a mission like the EXCITE Mission, it's not so much time spent in making the individual components, it's designing, developing and engineering all of the individual systems and parts. And that process still isn't done. So in the course of working on these two brackets, Ryan's team actually realized that the ideal configuration would be to combine both of them together into one larger part.

00:16:22:22 - 00:16:59:17

Ryan McClelland

So the final component will be much more complicated than either of these two components, because as we started developing this technology, we wanted to start simple with just, you know, two or three interfaces and then move up to this more complex part that's going to have something like five interfaces on it. So that, you know, complex part with all these interfaces hanging off it, you know, it just took a while to get the technology understood to the point where we could develop something like that. And we've been working closely with Autodesk to make sure that their tool is giving us the performance that we need from those more complex assemblies.

00:17:00:17 - 00:17:26:01

Pete Zelinski

Ryan was saying that iteration went into this version of the bracket. The designer tried different versions of this design to get to this final form, and each one of those iterations, each one of those versions of the design took about two days. Generative design is kind of designing the same way, going through iteration, but doing it orders of magnitude faster.

00:17:26:14 - 00:17:40:23

Pete Zelinski

So it is iterating at the rate of about 3000 iterations per hour. That is so much faster that it fundamentally changes things. It changes what the human designer does.

00:17:41:05 - 00:18:00:23

Ryan McClelland

It's almost a paradigm shift in the way that an engineer goes about their business. It really focuses you on thinking about getting the requirements right first, as opposed to just sort of coming up with something, maybe not thinking too hard about what it does other than connect things together. You really do need to enter all the requirements in first to get a good design.

00:18:01:09 - 00:18:34:17

Ryan McClelland

And one of the really powerful things about that is it gets you to design quickly so that you can pass it up the chain to other folks that are going to use the part. And you can see if you got those requirements right. So instead of the engineer being focused on making sketches and extruding and sort of coming up with these flat designs, it focuses the engineer instead on knowing what the requirements are and getting that right, and then also collaborating with this AI tool to get the parts that you want, which is really kind of a skill in and of itself.

00:18:34:17 - 00:18:44:21

Ryan McClelland

Like if you've ever used any of the AI systems like the Image Gen or the large language model stuff, you really sort of have to come to an understanding of how you work with it to get what you want out of it.

00:18:45:06 - 00:18:46:14

Stephanie Hendrixson

All right. I think we got this.

00:18:46:15 - 00:18:46:22

Pete Zelinski

All right.

00:18:47:10 - 00:19:08:07

Stephanie Hendrixson

So these are brackets designed for NASA's EXCITE mission. This mission is going to send a balloon the size of a football field up into Earth's atmosphere to study exoplanets. These brackets were created to hold instruments that are needed for that mission, and they're designed to be reusable. So the balloon is going to drop back to Earth and these brackets and everything will have to survive that impact.

00:19:08:16 - 00:19:11:01

Stephanie Hendrixson

They are examples of evolved structures.

00:19:11:10 - 00:19:49:15

Pete Zelinski

Evolved structures to realize geometric forms that a human designer using conventional design tools wouldn't create, wouldn't even know to produce, so the human engineer's role is different. Now, the engineers define simply the requirements of the component, lightweight, stiffness, the space available, where the assembly and connection points are. Then the generative design iterates, iterates, iterates within those conditions to realize an optimum form that meets all the requirements. Optimized forms like this aluminum bracket, this titanium bracket.

00:19:49:23 - 00:19:52:06

Pete Zelinski

And NASA isn't done yet.

00:19:52:17 - 00:20:07:13

Stephanie Hendrixson

Not done in two senses because there is a larger bracket that combines these two that is still to come for this mission. And NASA's going to continue to work with evolved structures. They're going to continue to use this solution to support future missions and future cool brackets.

00:20:08:09 - 00:20:25:18

Pete Zelinski

If your structures are evolving, if 3D printing is bringing you to components that accomplish their requirements in more sophisticated ways, we want to hear about it. Email us CoolParts@AdditiveManufacturing.media. We might make an episode of the show about your part.

00:20:26:03 - 00:20:47:05

Stephanie Hendrixson

And if you'd like to learn more about 3D printing technology and production applications, subscribe to our newsletter, The Build Up. You can do that at AdditiveManufacturing.media or at the link in the show notes below. Thanks for watching. Thanks again to our sponsor Carpenter Additive. In addition to supplying metal powders, the company also offers services, software and hardware to help AM users manage their powder.

00:20:47:12 - 00:21:04:19

Stephanie Hendrixson

One example is the PowderLife System, a combination of cloud based tracking software with hardware designed to make powder handling easier. Two key components are the PowderLife Hopper and the Automated Docking Station. Luke Boyer, manager of PowderLife Applications and Andrew Holliday Applications engineer, explained how the system works.

00:21:05:12 - 00:21:34:12

Luke Boyer

So today, when a user of additive manufacturing is receiving powder, they oftentimes receive it in either five, ten, 15, maybe a 20 kilo bottle, but they're receiving pallets of them and you're receiving ten, 20, 50, 100s of these bottles. The user has to look and segregate and store them appropriately so the bottles don't get mixed up. And it requires a lot of lifting and moving and labor.

00:21:34:21 - 00:22:00:23

Andrew Holliday

The components of PowderLife are all based around making powder management systems on the additive manufacturing shop floor easier to use for the operator, cleaner, as well as more traceable. Three of those basic parts of PowderLife are our PowderLife Hoppers or our storage containers for powder. The second would be the Automated Docking System that allows material to be pushed in and out of machines with no human contact.

00:22:01:01 - 00:22:25:07

Andrew Holliday

The third would be our PowerLife Online software system that allows you to trace this powder as it goes through your shop floor. The hardware, the software together just helps really streamline that and improve the final user's experience and let them concentrate on going from design to the part itself. Takes the headache of powder management out of the equation for them.

Related Content

Zenith Tecnica Manufactures 3D Printed Hardware for NASA Psyche Mission

The node components designed by Maxar Space Systems were well suited to the advantages of EBM AM due to their complex geometries.

Read MoreEOS, Hyperganic Partnership to Elevate Space Components

Integration of Hyperganic Core, an AI-powered engineering software platform, with EOS’ digital additive manufacturing solutions aims to advance the space propulsion field.

Read MoreArtemis I Has Launched: 3D Printing Applications for This Space Mission and Beyond: AM Radio #25B

On this episode of AM Radio, we discuss how additive manufacturing is enabling a new era of space exploration.

Read MoreAdditive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read MoreRead Next

Generative Design Improves Micromobility FUV: The Cool Parts Show #19

Arcimoto’s lightweight “Fun Utility Vehicle” gets even lighter thanks to parts that could only come from additive manufacturing. On this episode of The Cool Parts Show, some of the craziest automotive parts you have seen.

Read MoreImproving AM’s Efficiency with Generative Design

By engineering parts as opposed to designing them, MSC Apex Generative Design improves the efficiency of not only the final parts, but of the design and manufacturing processes as well.

Read MoreArtificial Intelligence and Additive Manufacturing Are Connected: AM Radio #36

Stephanie Hendrixson and Peter Zelinski discuss how AI and AM go together. There are already plenty of uses of AI in 3D printing for design, process planning and process monitoring, and the link will grow stronger as the “frictionlessness” of AI blends with that of AM.

Read More