Additive manufacturing is creating new opportunities for fiber-reinforced polymer composite materials. This has implications for the promise of AM and implications for the composites industry. In this episode of AM Radio, I am joined by Jeff Sloan of our sister brand CompositesWorld. We talk about composites replacing metal, large-format 3D printing for tooling, and other aspects of the overlap between composites and AM. Also, what does the acceptance and adoption of composites into part production, a disruptive technology in its own right before 3D printing came along, signal about the way ahead for an even newer disruptive technology, additive manufacturing?

Listen to the episode in the player above or find it in your favorite podcast app, or scroll down for the transcript.

Transcript

Peter Zelinski

Additive manufacturing for composites. Composites for additive manufacturing. Jeff Sloan, editor in chief of CompositesWorld, is my cohost on this episode of AM Radio.

Julia Hider

The AM Radio podcast is brought to you by the Additive Manufacturing Conference at IMTS. The leading industry event focused on 3D printing for production. Learn more at additiveconference.com.

Peter Zelinski

Hey everyone, I'm Pete Zelinski with Additive Manufacturing Media. Usually I'm joined by one other member of the Additive Manufacturing Media Team. Today, my cohost is Jeff Sloan. Hi, Jeff.

Jeff Sloan

How are you?

Peter Zelinski

I'm real good. So about Jeff. Jeff is a colleague of mine on a different brand. We both work for Gardner Business Media, Jeff leads our CompositesWorld editorial team. And we're going to talk about the intersection of composites and additive manufacturing, which is a big intersection. Would you agree, Jeff?

Jeff Sloan

It's big and getting bigger. Yes.

Peter Zelinski

So composites. So Jeff, this is the realm you cover. And you speak to an audience that is invested in expert in composites. Composites is like, I call it a once-emerging technology that has now emerged. And I say that because there are established applications that rely on composite materials, I'm thinking of aircraft. I'm thinking of wind turbines, arguably, maybe even like wind turbines, as we understand them today are made possible by composite material. So just get us started. Jeff, about your realm and your perspective, like forget additive manufacturing for a moment and talk about when we say composites what, what do you mean by that?

Jeff Sloan

So composite materials are as the name implies, our manufacturing material is comprised of two or more sub-materials, if you want to call them that. And when you put them together, the properties are greater than the sum of their parts. So typically, at least for CompositesWorld, when we say composites, we're talking about a fiber reinforced polymer matrix. So for instance, you might combine carbon fiber with an epoxy resin matrix to produce a finished part or a structure that is extremely lightweight, very high strength. Pound for pound, it’s the strongest and lightest weight material in the world and has a ton of applications. You mentioned wind blades, wind blades are the largest consumer of composite materials in the world, you could not erect a wind turbine today, unless you had composites. They're used in aircraft, the Boeing 787 and the Airbus A 350, most famously, are comprised of more than 50% composite materials by weight. So they've made a ton of inroads in a ton of applications, sporting goods, marine structures, automotive parts. Yeah. And as you mentioned, they were once emerging, I would argue that I think they're perpetually emerging. Because legacy materials have such a long history, I think it's easy to always think of composites is quote, new, even though they've been around and been involved in applied in manufactured parts and structures, the modern era of composites manufacturing dates back to the 1950s. So it's a fairly well established material and process, but relative to legacy materials, it just doesn't have that history, but a ton of capability. Lots of potential and lots of applications. So it's a pretty dynamic market and evolving very, very quickly. It's a very active and dynamic industry market. And we're seeing a lot of change. And that's bleeding over a little bit and to the additive manufacturing side, which I know we'll talk about in a minute. But that's basically where we're coming from. And what composites are, at least when we talk about composites in CompositesWorld.

Peter Zelinski

We covered an application in which a 3D printed composite bracket provided a cost-effective replacement for a machined metal bracket on The Cool Parts Show. Watch the episode.

Yeah, so let's go there. Let's now bring this into additive manufacturing. Perpetually emerging, you said, and 3D printing is now a means by which the applications of composites are expanding. Composites are a big deal in additive manufacturing, even by a lot of users who maybe wouldn't self-consciously be aware that composites necessarily is is what they're using. One of the big, big possibilities that 3D printing is enabling is the replacement of metal components with polymer and often reinforced polymer and I think we're just getting started with this. And polymers historically have been high volume because you need some kind of mold or some kind of tool to apply them, except now comes 3D printing and you don't. And it's a way to use polymer without tooling, which means it's a way to do polymer in low volumes, which means reinforced polymer materials have this entree to and so little, maybe even boring bracket like parts are now contenders for composites, thanks to 3D printing. And I say all that kind of to describe this is how composites looks in the context of additive. And from the perspective of 3D printing, and this this whole realm, like, is there a way to turn that lens all the way around? From the perspective of composites and people who think a lot about polymer composites? What is the view of 3D printing?

Jeff Sloan

So from the CompositesWorld, and I mean that, that from the brand perspective, but the world of composites perspective,

Peter Zelinski

We have the same problem with our brand. It's, it's so on point, like when we're using the proper noun, and when we're using the term is a distinction we have to make.

Jeff Sloan

Yeah. So thinking about this in the in the world of composites, this is an industry that has always catered to highly engineered parts and structures, because we have this massive diversity in fiber types, fiber formats, resin types, tooling types, and manufacturing types, you've got so much variation, and so much diversity, that there is no one composites manufacturing process that dominates, there's several, and there are several materials, there's not one material that dominates. And so you have this mixing and matching going on. And it's great because it allows you to customize some material to a given application. But because of this, there's not much standardization in the industry, that almost everything is customized, highly engineered for the application. And that's that's been the strength of the composites industry. But it's also been a weakness, that lack of standardization. The other challenge is that you're making the material as you make the part and unlike say, subtractive manufacturing, or you know, machining of metallic parts and structures, if you start with aluminum, ABC and you machine it, you're going to finish with aluminum ABC properties aren't going to change. And that's not true with composites, you're making the part as you make the material. And so it introduces a ton of variables that are sometimes difficult to control. The other challenge is that composite structures are an isotropic, they're not fully isotropic, there's sometimes cause is isotropic. And because of that, it's a it's a significant departure from the norm if you're if you're used to using metallic materials. So some people in the industry, the composites industry will say composites has actually been additive manufacturing, since you know, since the industry was created. And so what we're doing every day with composite materials is what additive manufacturing is just starting to do right now. At least when it comes to fiber reinforced polymers.

Peter Zelinski

Can I pause there a second? Yeah. So So first, let's paint a picture for the audience of composites the way they have been applied. And I think what we're talking about here is is layup methods, possibly applied by hand or possibly applied by a machine. Is that right?

Jeff Sloan

Yes. So in the most basic sense, you have a supply of materials. So let's say you're working with carbon fiber, and you might have some carbon fiber fabric, and that fabric needs to be shaped into a structure let's say an aircraft structure. That fabric needs to be integrated with a resin or infused with a resin. And there are lots of ways to do that. But typically, you'll cut the fabric to a given shape. You'll place the fabric in a mold, and then you'll add the resin you can add the resin under pressure, you can apply the resin via a process that's called pre impregnation. There are lots of ways to do it. And again, as I said earlier, there's so much variation that there are lots of ways to make a part but basically you are combining dry fiber with a resin you're infusing that resin into the into the fiber, you're curing it under temperature and or pressure, typically both. And that temperature and pressure consolidates that resin into the fiber and then hardens the resin and hardens apart. And when you are finished, you open a mold and you've got this finished composite part that that needs to be finished and typically finished in some way. Either by machining or trimming.

Peter Zelinski

There's a there's a tool though there's a mole, there's a mold. And yeah, and I want to I want to focus on that a sec, because when you say there's a view out there that composites has been doing additive all along, I get it and I respect that. But I guess to me, the real transformation of additive manufacturing isn't the adding it's the tooling lessness and it's the the chance to get a shape purely through data and purely through digital means. And I guess I say that out loud because the ability now to deliver not just composite forms, but also even get to continue with fiber forms without a tool is something that 3D printing brings. And I wonder, like, from the perspective of people already succeeding with composites, Are there big changes that that brings.

Jeff Sloan

The bottom line is yes. And one of the one of the big challenges in the composites industry is that if you're going to manufacture a composite part or structure, you have to come to the table with a lot of experience a lot of knowledge and history with the material and understanding how to design with it and how to produce good parts that are accepted by the customer, that knowledge and that experience doesn't come easily. And in one of the big expenses in that whole process is the tooling. And especially in aerospace tooling has to be typically metallic has to be low CTE and durable, because it has to go through autoclave cycles.

Peter Zelinski

Low CTE, low coefficient of thermal expansion.

Jeff Sloan

Right. And so you know, managing that thermal process, having tooling that is capable, it's a big part of it, then along comes fiber reinforced additive manufacturing. And it not only takes the tooling out of the picture, but also takes out that barrier, that barrier to entry that is traditionally existed, that you've got to come to the table with a lot of knowledge of composite materials. And so we have right now in the additive manufacturing industry systems that will produce fiber reinforced parts, it will produce good, acceptable composite parts right out of the box. And you don't have to have that knowledge and experience and understand what's happening in the box. But you do have to be able to, you know, produce a design that is manufacturable, which is, of course very possible with a lot of the systems out there today. But it really lowers the barrier to entry for anybody who's interested in getting into composites manufacturing. And without that tooling expense.

Peter Zelinski

You mentioned good, acceptable parts. And I want to draw a circle around that because composites as they're being applied today. They're on planes, they're on wind turbines there, this has been industrialized, and it's being used in production. Let's talk about industrialization, is there an industrialization path that composites has found, that also makes sense for this different way of applying composites additively?

Jeff Sloan

Yeah, so every end market that any manufacturing industry serves has to operate within the certification environment of that industry, in some environments are more strict than others. Aerospace is, for obvious reasons, the most strict because you're putting humans in tubes and flying them at 40,000 feet. And so that environment demands strict adherence to certain qualification and certification standards. And so composites have to work into that, and be a part of that and be integrated into that qualification environment. And they've done that. It's not always easy, and it's expensive and time consuming. That same system is now being we're starting to see that reflected on the additive manufacturing side. So for instance, one of the largest and most important qualification organizations within the composites industry, it's called NCAMP. It's located within the National Institute of aviation research at Wichita State University. And this NCAMP organization has developed a database of composite materials that are qualified and by qualified meaning they've been tested and assessed and characterized. And so we have some understanding what their properties are. So in Canada is now starting to be asked to qualify additive manufacturing systems, they started looking at particular systems made by particular manufacturers combined with particular materials. And they will assess those and qualify them and characterize them and then publish those material properties into a publicly available database that manufacturers can then draw on to produce parts using that machine.

Peter Zelinski

Here’s why I asked you about that. I think about composites the way that people today apply them. And it just seems really complicated. And really fraught and messy. Like, these aren't the right adjectives, but there's different layers. And it might even be a manual process. And with 3D printing, there's a lot going on. It has the same issue that you described earlier, the material is being made at the same time as the part and in fact that's happening on a microscopic level. And that poses challenges but it does seem like 3D printing allows composites to be applied in a way that's just more digitally rigidly controlled. Correct me if I'm wrong, but it seems like if composites as they exist right now, have gotten industrialized to the point that they've won certifications and qualified locations within someplace like aerospace, then it seems like composites 3D printing onto pretty readily be able to do it too.

Jeff Sloan

As I said earlier, that end market that end application matters a lot because it determines what the cost threshold is it determines the what the qualification environment is that determines what the design expectations are. And it often dictates materials used to, for example, if you were to walk into a wind blade manufacturing facility, and you saw the massive molds and tools are using to manufacture wind blades, and you saw the materials they were using, and then if I took you into a facility that's manufacturing aerostructures, for say, Boeing or Airbus, you would see completely different tools, you'd see completely different manufacturing processes, and completely different materials. The facility, the manufacturing environment really depends on the end market. And so as you said earlier, this is it can be a very messy process. And with additive manufacturing, then you have an opportunity to take down those barriers and capture in one system, the ability to manufacture a fiber reinforced composite part at the with a push of a button and the messiness and the required intelligence and knowledge and experience is for the most part taken out, you have the ability to bypass a lot of the hurdles and barriers that make getting into composites manufacturing such a challenge and produce good parts. And that's that's on the discrete parts side. We haven't even talked about making molds with additive manufacturing yet, but that you know, to answer your question about the complexity, and that kind of messiness of composites manufacturing and the ability to encapsulate that in a single system and to take down barriers, I think is going to be a potentially a huge driver for growth in the industry.

Peter Zelinski

Let's break there. You just mentioned we haven't talked about making molds yet. Maybe we'll talk about that when we come back. Sounds good.

Julia Hider

The AM Radio podcast is brought to you by the Additive Manufacturing Conference at IMTS, the leading industry event focused on 3D printing for production. Colocated with North America's largest trade show dedicated to manufacturing equipment, the AMC takes place September 14 and 15th at Chicago's McCormick Place. The conference takes a practical, applications-based look at the machines, materials and methodologies being used to 3D print functional components, including both tooling and end-use production parts. The event is designed for owners, executives and engineers as well as OEMs involved in durable goods manufacturing, joining the additive manufacturing team in Chicago for a day and a half of conference sessions and networking opportunities, find more information and register at additiveconference.com.

Peter Zelinski

Hi, welcome back. We're talking about composites and additive manufacturing. I'm Pete Zelinski with Additive Manufacturing Media and my special cohost for this episode is Jeff Sloan of CompositesWorld. We were talking about 3D printing as a means of making composite parts comparing contrasting finding the similarities with composite parts as they have been made so far for decades now in the industries where composites has been accepted. But on the way out, Jeff sort of dropped the clue that of course, additive manufacturing as a means of making tooling is potentially transformative too. And that means the layup methods of making composite parts could change through additive manufacturing, even when the part itself isn't even being made. additively Jeff, maybe just jump in there talk about what 3D printing brings to tooling for composites.

Jeff Sloan

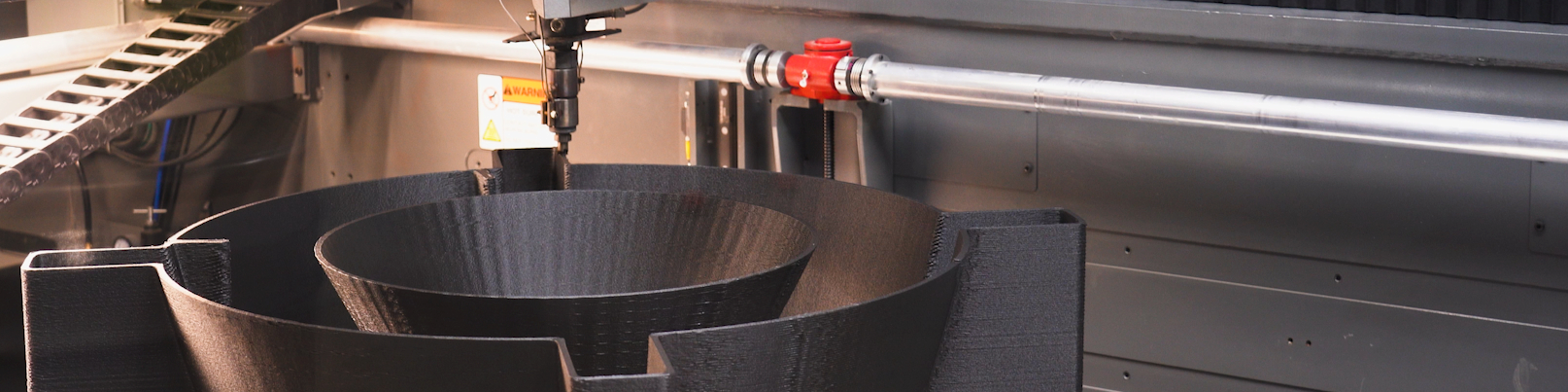

You know, I mentioned earlier that, especially in aerospace totally can be pretty expensive. Because of the CTE requirements, that coefficient of thermal expansion requirements. Basically, you need, you need tooling that doesn't react much to heat and pressure so that you can provide us dimensionally stable part. The problem is, those tools are expensive, and they take a long time to develop and to manufacture. So there's been a lot of focus throughout the industry for a long time on producing low cost tools. We use a material called tooling board to do that. It's machinable easily shapeable. But it's its ability to work well in a production by a full production environment is limited. So it's often reserved for prototyping and quick polls of parts. So there's this middle ground that has been unmet by any particular technology for a long time, which is the ability to produce production capable low cost tools quickly, large format, additive manufacturing has stepped in there and so there are companies like Cincinnati Inc, which makes a system called BAAM, Big Area Additive Manufacturing. Thermwood which makes the LSAM system. Ingersoll makes, it's a system called Masterprint and these are all very large-format systems often gantry-based and also typically integrated with some sort of machining option to and the ability Here is to lay down a thermoplastic material typically ABS reinforced with carbon fiber. To quickly build a mold, there's a lot of finishing that is involved here, you know, once you build them all build the structure you've got, you know, you've probably familiar with the kind of the striated, layer-by-layer look of these parts, that has to be finished and sanded and sealed. But there is an ability here to very quickly and efficiently and inexpensively make molds that do have some capability to produce production parts, that means they can go through an oven or an autoclave. Maybe not for as many cycles as a metallic tool, but that capability is there. And the ability to do that so quickly and relatively inexpensively is huge. And so that is one area where we're seeing just a ton of activity and the ability to make these tools and molds quickly using these large format systems.

Peter Zelinski

Yeah, we here at Additive Manufacturing Media love the striated look. We started this conversation, set it up by talking about the overlap between these two worlds additive manufacturing composites. And you you listed some of the machine builders succeeding in this area being able to 3D print big tools machines able to do that Cincinnati's BAAM, Thermwood, Ingersoll. So these are, these are all machine providers very relevant to the world that you're covering and serving. And we know them really well, too. And speaking in particular, of building tools out of polymer composite, there is this phenomenon that we see throughout 3D printing and these big composite builds, too, and that the users who start out making tools find themselves drawn into making production parts. There's a company in here in Ohio with us, we've covered from time to time Additive Engineering Solutions, and they actually founded a business using BAM to make really big tools, but they're now making really big production parts. And we've, we've gotten to cover some of that whole components for the for an automated sub and housings for flight simulators. And it is it is interesting how 3D printing as a means of applying and serving composites at that scale, you could be making tools, you could be making parts on the same platform.

Jeff Sloan

We actually went across, we run into this a lot within the composites industry, it's not uncommon for us to see a manufacturer enter the market with a given technology. Maybe it's a technology they've developed themselves or it's a material or it's developed by somebody us and are we one of the first market with it. And I know additive engineering solutions is one of the first to market with large additive manufacturing systems, these large format systems. And so it's not unusual for us to see as a company come in with an idea about how they're going to serve the market, you know, we've got this machine these this material. And we're going to serve this part of the market making these kinds of parts. But often the market doesn't react the way you think. And so suddenly, if you've got customers who see you have this capability, they may be asking you to do things you didn't anticipate you would be doing. And so having these large format systems, as you mentioned, like at AES, it's not too unusual to hear somebody say, you know, you've got these big machines. And there's a capability here that we'd like to take advantage of. And soon you're steered into producing parts and deploying this material in a way that maybe you didn't anticipate, but certainly is made possible by these systems like yeah, that's the story of additive right now.

Peter Zelinski

Yeah, it's even the case with a AES that we're talking about like, one of the stories we did has to do with how they were asked to make molds for concrete preforms for this big building being raised in in New York. And concrete preforms are usually made with lumber, but they had to make so many of them that the AES got the opportunity to make them out of polymer composite. And it's just this, it's this application they never expected and, and I think in both of our worlds, Jeff, like, that's what's really fun. And that's the real promise of it is just what these processes and materials are going to be when they grow up is still to be determined.

Jeff Sloan

It kind of feels like there's a Wild West aspect to additive manufacturing. Sometimes it's a highly dynamic environment with a rich diversity of materials. And it kind of feels like we're just in the infancy of understanding how they can be applied and what the opportunities are. And I just wondering if you see that across the industry, or if it's just my perspective on how I see it evolving on the composite side?

Peter Zelinski

Absolutely. Yes. Wild West. I don't know if that's the analogy. Exactly. The promise of additive manufacturing is coming into focus. And it's huge and transformative and can utterly change big things like supply chains, but to realize that promise, you've got to utterly change big things like supply chains. And then like, that's where we're at right now. And there are so many different aspects of a manufacturing enterprise that have to rethink how they relate to one another. Design and manufacturing have to talk to one another a different way. And kind of have to cohabitate in a way they never did before for the full power of additive to come out. And we're figuring out how to do that. And to a certain extent, it's, it's waiting for entirely new products to be developed and launched that offer opportunities that offer kind of clean slates to try to not just put new processes in place, but new systemization and organization in place, and we're gonna see all that happen. That's the one big remaining area I think I want to I want us to talk about a little bit because exactly the phenomenon you're describing. Composites has gone through this, like there was a time decades past where polymer composites as we understand them today looked like a pretty crazy way to make a part. And there even was there even was a wide openness, a wild west aspect, if you will, about, like, what parts should they even make, and even some imagining about roles they'll play that they ultimately prove not to play? And do you see any potential parallels in the history of composites and the way composites gained production, industrial acceptance and found the roles they have so far. Do you see any parallel with that in the way that you anticipate additive manufacturing might play out?

Jeff Sloan

I think the biggest parallel I would see is, is in how materials and technologies are integrated within a manufacturing community. And so to me, it often comes down to two kind of big buckets that you have to look at. The first is the technology meaning process and materials and capability and can the materials do the job. And if they can do the job, where do they fit in which markets and what kind of parts. And so that's the technical side, the other bucket is the socialization or social side, meaning there is always resistance to change within any end market, there's always resistance to new material, there's always resistance to deviation from Legacy materials. And so for a new material or new process to come in and displace that legacy material, that new material has to earn its way into that application. So we say that a lot in the composites industry, they have to, quote, earn their way onto a program or onto a part or product. And so that process that evolution has been a long, long time coming. So you know, the modern era of composites manufacturing goes back to the 1960s, when you know, the Boeing 737 had a few composite parts on it. And it takes us all the way up to today where we've got aircraft that are more than 50% composites by weight. And I would argue that future aircraft that will be developed by Boeing or Airbus, or anybody else are going to use composites in similar ways, so that evolution has been such a long time in coming. And some of that has been the technical adoption and acceptance. And then a lot of it's been the social side and displacing existing materials and developing the faith within design and manufacturing communities to use this alternate material. I think we'll see a similar thing with additive manufacturing, but probably at a much faster pace, I think the evolution there is going to be much quicker because of the ability to kind of encapsulate the manufacturing in a closed system that is not so fraught with manual labor and variation and everything that all the messiness that, you know, you mentioned earlier with composites, because it's captured in this one system. And because you've got really robust design tools up front that helped the user, create parts that you know, meet the needs of the application, I think we'll see that much faster.

Peter Zelinski

I'm struck Jeff, by the way, you said that word social a couple of times, and just kind of kind of alluding to the people aspect of a new technology winning acceptance. I regret a little bit like using the word messy previously, because when you think about it, actually, all of these different technologies are messy in their own ways, like all these different production methods. They have their own demands and limitations and requirements. And it's just once the people involved get to a point of mastery and familiarity over that messiness over those requirements and it becomes part of the air they breathe the acceptance path, in part, you sort of talk about how additive like it all takes place in a box Yeah, in part like that's, that's what's super liberating about it. And in part, that's, that's the challenge too, because any kind of certification in control has to monitor and accomplish a whole lot all at once in terms of the material properties that are coming together along with the geometric form, and some kind of industrial predictable repeatability in both of those areas. And we're figuring out how to do that. And in part, it's going to require types of validation that are different than what we have accepted before. I think the various regulators in these different industries are aware of that and want to help facilitate that they have as much interest in the industries they serve succeeding as, as the manufacturers within them. But the path is clear in terms of the questions that have to be answered. And we will find answers to these questions, how to predict processes, how to control them, how to certify them. Like the way forward is clear. It's just What's not clear is the timing. But I guess, what is really striking and promising to me kind of bringing it all the way back to where we started this conversation through 3D printing composites are finding applications by users who aren't really self-consciously aware that they're using composites. And that to me is kind of a sign of of composites, at least reaching something like maturity, a technology has arrived. If we don't talk about that technology so much anymore as a discrete thing. Additive still has a ways to go before it gets there. But yeah, composites did it, like additive can do it too.

Jeff Sloan

Yeah, I think we talked sometimes in this industry, but democratization of composites, and acceptability, and taking down those barriers that I talked about earlier. And I agree, if you we get to a point where somebody is deploying a material without regard to the identity of the material, or the history or the backstory, or even a fundamental understanding of you know, how the material behaves, or what it does, just understanding that serves their need in the finished part in a way that no other material can that I that has to be considered a victory of some sort. You know, if you're in the manufacturing industry, it's easy to identify with a material or process. If you're, if you're wedded to it, you work with it every day, and you're you're have some allegiance and faith to it. But to somebody who's just trying to make something that does something in that works and meets the need and is selected by the customer. You don't really care. And you mentioned earlier that I mean, there is an aspect of that in additive manufacturing, where you have a lot of material choices, and you're most interested in the materials that achieve the goals that you're trying to reach. So I think we're headed that way. Like you said, we're not there yet, but I can see that we're definitely on that path.

Peter Zelinski

Jeff, thanks for having this conversation with me.

Jeff Sloan

Thanks, Pete. I appreciate it.

Peter Zelinski

So I've been talking to Jeff Sloan of CompositesWorld. Learn more, CompositesWorld.com. We're going to include a whole lot of links to articles related to stuff we've talked about within the show description. If you like the podcast, please subscribe. Give us a rating — give us five stars, and Jeff Sloan as well has a podcast, CW Talks. Search for that wherever you're listening to this podcast. Subscribe to both. Thanks for listening.

AM Radio is recorded with help from Austin Grogan. The show is edited by Alex Lytle and Stephanie Hendrixson. Our artwork is by Kate Bilberry. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in Cincinnati, Ohio. I'm Pete Zelinski. Thanks for listening.

Related Content

Next-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreVideo: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

Read More3D Printed Spares, Electrification and Cool Parts: Top 10 Stories of 2022: AM Radio #31

Our top articles and videos from 2022 reflect increasing use of additive manufacturing for replacement parts; growing applications for electric motors; and a maturing user base. Read through the top 10 list or listen to the AM Radio podcast episode all about these stories.

Read MoreLouisville Slugger Uses Formlabs Technology to Accelerate Innovation

Louisville Slugger relies on Formlabs’ Form 3 stereolithography 3D printer to create both prototypes and manufacturing aids for designs of the composite and aluminum bats swung by youth and collegiate players.

Read MoreRead Next

3D Printed Composite Bracket Versus Machined Steel: The Cool Parts Show #41

Can a 3D printed composite bracket work as well as one machined from steel? Can it also be faster to make and cheaper to produce? In this episode of The Cool Parts Show we explore a new way of manufacturing a bracket for a helicopter door hinge, and similar small parts today made from metal.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreAerospace Applications for 3D Printed Composites: AM Radio #15A

3D printed composites are taking the place of traditional metal parts in a specific niche of the aerospace industry.

Read More