Arch Additive in Scarborough, Maine, has made the jump from demonstrating it can make implants effectively through electron beam melting to now going into full production with implants made this way. Succeeding at one does not automatically translate to succeeding at the other, says company president and founder Brian McLaughlin. Scaling up to production so far has not involved adding more machines; it has involved changing personnel, process and procedures — and this kind of development continues.

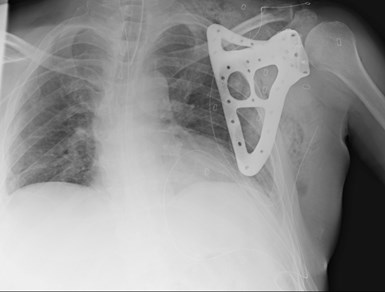

Products made by Arch Additive that have entered production include implants for knee, hip and spine surgeries, with shoulder implants coming soon. Spine implants are seen at the top of the page. The set of parts here is a demo illustrating how hip implants are stacked during the build.

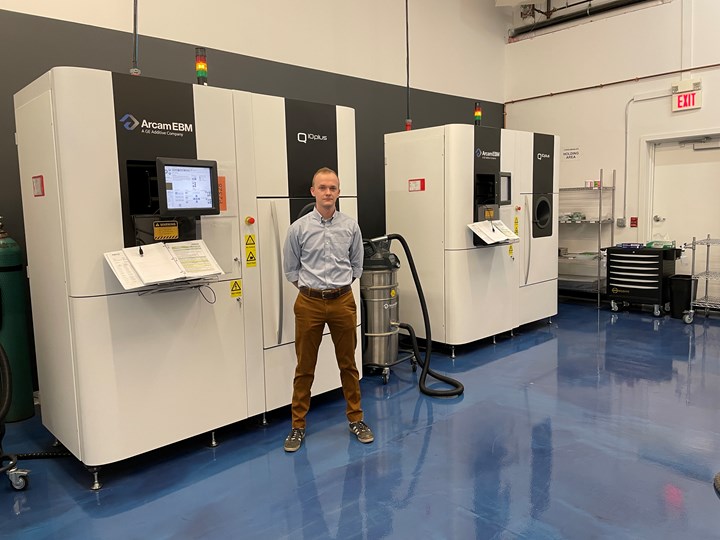

I first visited the Portland-area manufacturer in 2020. (It was Amplify Additive then, prior to the company’s acquisition by Arch Medical Solutions.) At that time, McLaughlin pointed out to me how the facility is equipped and ready for seven more machines like its three GE Arcam EBM systems. Since then, the company had added a machine not to expand production capacity but to diversify — it now has laser powder bed fusion through a machine from EOS. On my return visit in 2023, I talked to McLaughlin and VP of operations Jeff Laniewski. Adding machines is not the most effective way to expand capacity, they say, or not the most effective way for Arch Additive right now. Instead, the company has found greater productive capacity by tightening the window of time needed for machine changeover and service, and by reducing the possibility of production being lost through error. These kinds of improvements have proven to be both necessary and powerful, and they have been the focus of the company’s efforts to date in transitioning to production.

Plus, McLaughlin notes, the AM capability is so productive — particularly given EBM’s freedom to nest parts in three dimensions of the build — that as yet the company is employing only 20 percent of the productive capacity its current machines might potentially provide.

Arch Additive founder Brian McLaughlin (left) talks with VP of operations Jeff Laniewski. McLaughlin is holding a hemipelvic implant. Patient-specific implants such as this — that is, unique one-off parts rather than batches — represent an important share of the company’s production. Photo credit: Arch Additive

Production In Two Phases

Arch Additive serves small and mid-size companies developing new medical implant designs that leverage AM. The very largest and best-known medical device makers generally are not Arch Additive’s prospects, in large part because many of these companies have their own resources for additive design and production. But medical device startups and smaller producers need a source that can manufacture quantities of additive parts in two distinct and separate phases.

First, something like initial production is needed just to create enough parts for FDA evaluation of the new implant design. Then comes the wait for regulatory approval. This “could take months or could take more than a year,” McLaughlin says , and this interlude is “out of our control.”

But then, coming after that approval is full production of implants as a commercial product for surgeons and patients. During my first visit, Arch Additive was doing almost exclusively the former part-making — production for the sake of testing. Today, its production activity is split between implants in development and headed for FDA evaluation, and implants that have cleared this step and are now being sold. These include implants for knee, hip and spine surgeries, with production of shoulder implants coming soon.

Yet even this production might not be the final phase, says McLaughlin. Any one of these products currently in production at the Scarborough facility has a large potential upside, he notes. One of these small companies marketing the implant might be acquired, suddenly giving that implant access to a much larger market necessitating a much larger production rate. In short, the 80 percent of potential capacity currently unused is not as large of a buffer as it might seem, and Arch Additive might be closer to needing to add new machines than today’s activity level indicates.

Before this happens, a production system should be in place allowing for the most efficient use of every production machine. It has taken time for the company to get to this, Laniewski and McLaughlin say, and they are candid in describing how stumbles have turned into learning experiences along the way. Now, that system is mostly established. Getting from additive manufacturing to production additive manufacturing has been a shift, and for Arch Additive, various measures have been instrumental to that shift. At the Scarborough site, the formula for production AM now includes all the following:

1. Systemize contracts and require redundant approvals

One costly stumble Arch Additive made involved a production order requiring serial numbers to be incorporated into every 3D printed part. The company neglected to do this. A costly production run was scrapped. Again, a learning experience — and one that company leaders never want to have to relearn.

The solution in place today is this: “We now turn every contract into a checklist,” Laniewski says. No surprise, contracts for medical implants can be complex, plus every one of Arch Additive’s small customers has special requirements that make them distinct. The requirements have almost always been met. But to cure the “almost” part of that statement, the team’s process now includes the formal translation of every contract, with all its provisions, into a documented checklist of production steps and benchmarks. Just as importantly, no single person is alone accountable for ensuring every step on any of these checklists is performed. For every job, at least two of the company’s five employees must independently validate that the contract steps were satisfied.

Laniewski, a career operations professional, has implemented procedures like this in roles with other companies. A motto he applies: “Don’t do things until you get it right; do them until you can’t get it wrong.”

Arch Additive engineer Kaitlyn Webber inspects screws made for customer OrthoFundamentals. This company worked with Arch to realize a screw design made through EBM that is far more effective for natural bone integration than a conventional machined screw.

2. Tighten supplier discipline and aim for vertical integration

“We have great relationships with our suppliers,” McLaughlin says, but part of getting to this has been turning away from suppliers not able to maintain tight windows of responsiveness allowing the company to succeed at on-time deliveries.

And even with a strong network of suppliers, coordinating with external companies still is where lead time is generally lost. Getting to even tighter lead times therefore means developing capabilities in-house.

Machining seems likely to be an example of this, he says. Machining today draws on a particularly tight supplier relationship, because machining is a specialty of the Arch Medical Solutions group. Parts are sent to a sister site for this work. Still, “There are logistics involved,” Laniewski says, and just this much can be enough to challenge or compromise delivery promises. That is why the Scarborough site recently added simple machining capability; more complex five-axis machining capability is a natural next step that is likely to come.

Even so, certain steps in additive manufacturing are difficult to vertically integrate. Hot isostatic pressing (HIP) is perhaps the most notable of these. The company’s preferred supplier for HIP is on the opposite coast in Portland, Oregon (yes, parts are routinely shipped from Portland to Portland), so the best option is a level of collaboration with this supplier sufficiently close to allow for clear communication of timing and expectations.

3. Seek new hires ready to embrace production

AM is a production process based on a capability originally used for prototyping, and something like a prototyping mindset still informs many people experienced in AM, McLaughlin observes. For this reason, he says he has found success by recruiting new hires who have not been employed in an additive manufacturing operation before.

Two engineers, Emma Sperry and Kaitlyn Webber, are recent graduates of the University of Maine.

The company’s AM technician, Ben Henckel, is a current engineering student and a former Navy machinist. He applies discipline learned in the Navy to changeover and service on the EBM machines, and in this way is able to keep these machines producing while working for the company just 25 hours per week.

AM technician Ben Henckel is a former Navy machinist now overseeing changeover and service of Arch’s EBM machines. Arch also has a third EBM machine in addition to the two seen here.

4. Make engineers into customer champions

Sperry and Webber, along with McLaughlin, all serve as project managers. Each of them is charged with a set of customer relationships, and in each case, the customer’s team members know that this person is their contact and the one with whom they have a direct working relationship.

McLaughlin says establishing this system has been valuable in part because the key to meeting customer requirements is understanding those requirements. Creating a contact, advocate and champion for every customer is an aid to understanding that customer’s intent, and therefore translating considerations like contract language into precisely the outcome the customer hopes to see.

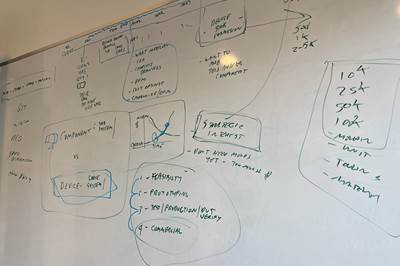

5. Routinize planning; rely on this over digital tools

A tool like ERP software is hard to imagine applying to Arch Additive’s process, Laniewski notes. He says just one example of the challenge is that patient-specific implants — unique custom implants tailored to digital scans of individual patients — now account for a not-inconsiderable share of the company’s production. The company sees seven to ten of these opportunities per month, and the demand is growing. Each of these implants is a production part, albeit in a quantity of one, and it is likely to be produced by nesting it within a build of unrelated parts. The other parts might be a batch of non-custom implants, or, “If we have four patient-specific implants of the right size, we might make a build out of all these,” he says. Blending of separate jobs into shared cycles like this is difficult to manage efficiently with an off-the-shelf manufacturing software solution.

Another challenge is allocating material cost in AM. The EBM build chamber must be filled with powder to complete production, but most of that powder is not used in parts, and the unused powder can be recycled to a limited extent. Therefore, “If titanium powder costs X per kilogram and I can recycle it six to seven times, then what is that material’s contribution to the cost of the product?” Laniewski notes.

There are reasonable answers to questions such as this, but the way Arch Additive has found them is through ongoing internal dialogue. Conversations around delivery requirements for current jobs lead to scheduling plans and the designs of nested builds. Conversations around customer material requirements lead to assignments of particular grades of titanium. Rather than finding a software solution for planning, Arch Additive has aimed instead to routinize and systemize the form and frequency of its team conversations.

Next: Automate Where Possible

The additive builds are unattended, but preparing for a build is not. McLaughlin sees the best hope for future streamlining and efficiency gain to be found here.

For example, the company is involved in a project with the Roux Institute at Northeastern University in Portland aimed at developing software to automate lattice creation for parts using lattice regions in their geometry — an engineering step that computer intelligence likely can perform more quickly and capably than the way lattice design is performed manually today.

“We also expect to automate steps that are not even part of our preparation currently,” he says. For example, surgical screws today are produced via EBM at hundreds of parts per build. Occasionally, a build includes some screws that are found to be unacceptable. Why? McLaughlin knows where to look for the answer. Seeking to maximize productivity by pushing build density and geometric file size can lead to overheating in some regions and the corresponding effect called “swelling,” yet there are various specific reasons this might happen and therefore various possible adjustments that might be made. Software leveraging AI could find the response and control for precision on a per-part basis. Scrap is lost production, too (as every producer knows), so finding ways to control against this loss will be one more way Arch Additive can increase its output per machine ahead of the day when more machines are added.

Related Content

AM 101: What Is Hot Isostatic Pressing (HIP)? (Includes Video)

Hot isostatic pressing has long been used for metal castings, but is now being applied as a valuable method for closing porosity in metal 3D printed parts.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreAM 101: NanoParticle Jetting (NPJ)

The proprietary process from XJet builds ceramic and metal parts using nanoparticle suspensions. Learn how NPJ works in this introductory article, part of our AM 101 series.

Read MoreRead Next

Stryker Using Additive for Implants

Using its “AMagine” process, Stryker creates components with a titanium alloy that mimics bone.

Read More3D Printing as a New Product Launchpad

With 3D printing, Minnesota manufacturer Resolution Medical offers a fast, affordable route for individuals and small to medium-sized businesses to get new medical devices and other products off the ground and into the marketplace.

Read More3D Printed Scapula Customized for Patient: The Cool Parts Show #25

A patient treated for a tumor of the shoulder blade was able to preserve full use of the arm thanks to an implant tailored to the precise form of the original scapula and made through electron beam melting.

Read More