Artificial Intelligence and Additive Manufacturing Are Connected: AM Radio #36

Stephanie Hendrixson and Peter Zelinski discuss how AI and AM go together. There are already plenty of uses of AI in 3D printing for design, process planning and process monitoring, and the link will grow stronger as the “frictionlessness” of AI blends with that of AM.

With the arrival of resources such as ChatGPT and Dall-E, artificial intelligence (AI) is a widespread topic of discussion. But AI has been aiding additive manufacturing for years, to the extent that the applications are coming to seem pervasive. Stephanie Hendrixson and I talk about the link between AI and AM, both as we see it today and as we expect to see it in the future. What AI and AM have in common is frictionlessness — in terms of offering instruction, as ChatGPT shows, and in the ease of starting production without need for hard tooling that 3D printing makes possible. What will we see as these two advancing technologies increasingly come together?

Transcript

Stephanie Hendrixson 00:04

How is additive manufacturing advancing with artificial intelligence? What impact will AI have on the future of design? Did ChatGPT write this podcast? Find out on AM Radio.

Jodee McElfresh 00:27

This episode of AM Radio is brought to you by Formnext Forum Austin, the first of a series of Formnext events coming to the United States. Find more information at formnextforum.com.

Peter Zelinski 00:41

Thanks for listening to AM Radio. I'm Pete Zelinski with Additive Manufacturing Media, and I'm here with Stephanie Hendrixson. Hey, Stephanie.

Stephanie Hendrixson 00:47

Hi, Pete.

Peter Zelinski 00:48

So you want to talk about artificial intelligence?

Stephanie Hendrixson 00:53

Absolutely. This is something that I think has been on everyone's mind with ChatGPT being so accessible. You and I have both played around with it. Everyone is thinking about artificial intelligence right now. It feels like however, you and I on Additive Manufacturing Media have been thinking about AI and AM going together for quite a while.

Peter Zelinski 01:13

Yeah, we've been looking at this quite a while, additive manufacturing, artificial intelligence, they are interconnected, they go together. It's a difficult topic to cover to report on because it is invisible. The mechanism of it is invisible. It's hard to see it happening. But additive manufacturing, digital manufacturing process and artificial intelligence, greater mastery over digital information, one flows into the other. We've been looking at this kind of for years, our first theme issue of the magazine on machine learning was I think something like five years ago now.

Stephanie Hendrixson 01:52

Wow, it's been a while. So you mentioned machine learning right there. And as I understand that, machine learning is a subset of AI. Do want to just quickly talk about the difference.

Peter Zelinski 02:00

So yeah, let me try as best I can, machine learning. I see machine learning as programming that is just infinitely good at accepting rejection and accepting failure. Just learning from making correlations from lots of fails. Lots of rejections. And what's striking about that, like as, as, as humans, I bet that's one of the biggest thing that gets in our way, we get rejected only so many times. And it's like, we throw up our hands and “Okay, I can't learn anything here.” And machine learning is finding what there is to be understood by trying every possibility very quickly, and and looking for what gels what works. Artificial Intelligence encompasses machine learning. And we are I'm watching us talk a little less and less about machine learning and more and more about artificial intelligence, because what artificial intelligence brings is more of the human facing part of it, not only finding the correlations, but also further correlating that to the kinds of things human beings asked for, and the kinds of ways that they asked for it in order to serve up these findings. And yeah, you mentioned ChatGPT. So, this is now a very public widespread example of what that looks like. Human-facing machine learning delivering its correlations as best it can.

Stephanie Hendrixson 03:29

Yeah. And to be clear ChatGPT did not write this podcast, we don't script it, actually. So, there was not really a good way to do that anyway. But, I think that's a pretty fair assessment of what machine learning is, what AI is, how to think about it in context, we're not going to spend a lot of time, you know, getting into the details of is this machine learning, or is it AI and where the line is, but just kind of laying that out at the beginning, I think is a good, a good place to start. So I think what I'm seeing is a shift in that first issue that you mentioned, like five years ago, when we first started talking about AI and potential applications for additive. And the way that we talk about it more recently. And what I mean is, in the early days of additive manufacturing, there are all of these different variables. I mean, there still are all of these different variables. But I feel like the efforts around artificial intelligence and like using that data, it was much more granular. It was like if you're going to apply these tools, you need to know every single thing about the build at this moment, you need to know the laser power, the spot size, the hatch pattern, like all of these different things and take that all into account, and artificial intelligence that like in the last couple of years has taken additive manufacturing kind of beyond thinking that way.

Peter Zelinski 04:39

So that's interesting, that shift that you perceive. So let's talk about the before and after of that shift. Our earliest engagement with artificial intelligence, with machine learning and seeing how it was being applied to additive manufacturing. Laser powder bed fusion, and all of these different process parameters and the outcome of the build that results from different combinations of parameters. And machine learning was being applied, to try to sort all of that out to try to avoid the need for trial and error, avoid some of it at least by equipping systems through machine learning to know what the outcomes were going to be of certain sets of process parameters. To some extent that's still going on. And I think of your reporting recently, Stephanie on Nnaisense.

Stephanie Hendrixson 05:30

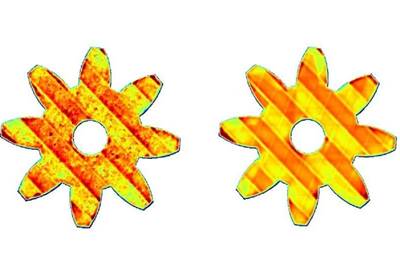

Yeah, so this is a great example of exactly what I'm thinking of here. Nnaisense, they're a Swiss company. It's spelled N-N-A-I-S-E-N-S-E. And what they have developed is an AI for predicting how laser powder bed fusion builds will will play out. So they worked with EOS on this, and created this system where each layer of the build is matched to a digital twin of like the simulated build. And kind of the striking thing about this example is the model that they've built, it's not looking at all of those individual parameters. It's mostly looking at the optical tomography heat map for each layer. So the heat map and the geometry and a couple of just other small data points provide enough information for the computer to learn kind of what's going on in the build. So it matches that heat map to what it has predicted the heat map should be. And it can sort of raise a red flag and say, hey, something is going wrong, something that we didn't anticipate or serve as like a way of qualifying that part after the fact. And the interesting thing about how this model was trained, they use not machine learning, which implies that someone is structuring the data like there is a human kind of labeling like 'this is a defect, this is a defect, look for these things'. Instead, what they used is a method called self-supervised learning, where they had all of this information, all of these past builds from EOS that they were able to train the system on. And as a result, like it's a much more scalable way of getting to an AI model. But it is kind of more of that like black magic, black box kind of method where you don't exactly know what's going on in the computer, but over time, and with enough information, you can get to a pretty reliable model.

Peter Zelinski 07:11

Argonne National Laboratories is doing research kind of similar to this using machine learning with thermal signatures of laser powder bed fusion builds, like you described, but Argonne is pointing these really powerful X-rays at the build in real time and watching microscopic pores and their formation and the machine learning is correlating one to the other. What does a thermal signature look like that leads to this particular type of defect? And trying to establish those correlations so well, that just the heat signature is enough, seeing that particular heat signature indicates this particular defect or set of defects is about to occur. That's a very specific input-output application of machine learning. And as you described, we've seen the use of artificial intelligence kind of spread out and flourish across all these different uses in additive manufacturing, and not necessarily this one that we're talking about. Like you can get good laser powder bed fusion builds, and we know how to and I think we're figuring out, you don't actually have to master every single detail of the input to get the output macroscopically that you're aiming for. So kind of pivot us to the now like, get us started. What's an example of kind of where we're seeing additive and AI interconnect today.

Stephanie Hendrixson 08:47

So I don't want to imply that this research and these other things that we've been talking about are not being applied today. But, I think we are seeing AI like infiltrate additive in some different ways, like different than what we anticipated five years ago when we first started talking about this. So, one that I see happening is this whole issue around part assessment like deciding 'Should I 3D print this part? Can I 3D print this part?' And maybe like 'How should I think about that?' So, just a couple of examples that I've encountered, like Castor, this company offers a tool for basically like looking at your part catalog, like analyzing 2D drawings, analyzing CAD, whatever it is that you have, and helping you decide is it going to be technically possible and economically viable to convert this conventional part to an additively manufactured one. I don't understand exactly how the system works, but I understand that it uses some combination of computer vision and machine learning, and is maybe also like learning from the different parts that have been uploaded over time to make these assessments. There's taking that kind of a step further. There is another company in Israel that I've talked to called PrintSyst, and they have a sort of similar system but it's more like a part-by-part basis, where you can upload your design file and it'll spit out a label that says printable, warning or not printable. And it's basically just like a really quick go/no-go assessment for your parts. The really interesting thing to me here is that warning categorization. So these are parts that could be 3D printable, but they have a couple of problems, there are a couple of tweaks that you might need to do in order to make it possible to print them and the software will kind of walk you through that. And the AI aspect of this is that the software does allow for human overrides. So if you look at a part that has that warning on it, and there are some, you know, issues that have been highlighted in the CAD drawing, and you start to make tweaks, the software is going to learn from that. And so next time, a part that has similar issues comes up, it's going to be better able to help that future user, make this assessment and make those decisions.

Peter Zelinski 10:48

So, humans making decisions. So, what that reminds me of is, I came across a proposal from the US Army, and they're looking to sponsor research for the very purpose you're describing. They're concerned with lots of replacement parts and the need for servicing all of those replacements and what what should be machined? What should be 3D printed? Right now, it is necessary to rely on human expertise, basically manual intervention to figure this out part by part. And is there a machine learning approach to sort that out way more quickly? I guess what else that makes me think of is this emerging discovery of all of the places in applying additive manufacturing where human judgment is applied, that provide some opportunity for artificial intelligence. And it turns out, it occurs at different parts of the process way before the build is actually happening. And you started super early, you talked about part selection. So the next step after that, after you've selected a part, you've got the model, it's preparing it for 3D printing, and and I'm seeing artificial intelligence find applications for that. Also, one really intriguing one, and I don't know a lot about this yet. But there's this company in the UK software company, AI Build. And they have this product called AI Sync. And it is GPT-based software for slicing. And what it appears to be able to do is conversational slicing. So I could look at a model and say to the software, 3D print this in one-millimeter layer increments and give me square pattern infill and increase the infill density as it gets closer to these thin parts of the model. And I might be expressing this a little inaccurately, but it's basically that. It is AI-enabled conversational guidance of slicing as an alternative to kind of software interface, clicking options, kind of setting up the build. That's really intriguing to me, because it strikes me that yeah, that is an exercise that's knowledge driven, but not all that much more complex than all this host of other things we're seeing ChatGPT do.

Stephanie Hendrixson 13:12

So that's interesting on two different levels. So you've described this way of basically like applying ChatGPT, almost, something like that, to slicing, like making a really conversational way of talking to the computer and explaining what it is that you want, which is, which is really compelling. The other side of that is I would imagine that AI Build is maybe learning from each of those conversations and trying to get better at slicing from the things that users are asking for.

Peter Zelinski 13:39

Yeah, I assume so. And like, let's be real here, like you and I don't know exactly how all of these AI systems work. They're invisible. But the system learning, the system getting better, that's the assumption and the expectation and the promise of AI. It applies to process, too, right? Additive manufacturing processes, and the quirky ways that they behave and getting better at monitoring them, too.

Stephanie Hendrixson 14:04

Yeah, and there are some things that AI is making possible in additive manufacturing right now. So, like I'm thinking of this story that our colleague Julia Hider wrote about Inkbit, which is a company that offers this material jetting style 3D printer, but it's for industrial parts. And if you think about material jetting, like if you have any kind of first impressions of it, it's probably that the materials aren't great, and they're kind of brittle, and like they're not really suitable for production. And actually, what Inkbit has been able to do is use artificial intelligence, use a vision system to be able to print with more viscous materials to be able to control the materials better, and they're able to get some really great results out of that. So that's an example of AI kind of getting into the process and not only, you know, improving it over time making it better, but actually like make something possible that wasn't possible before.

Peter Zelinski 14:53

Right Inkbit, material jetting viscous material, very high production rates is what they're trying to achieve and how is this viscous material behaving in very short increments of time during production? No human overseer could monitor this, but the AI is monitoring it and making decisions like oh, the material didn't fill this layer in quite the way expected, so respond by forcing more material into this little corner or this detail of the part in order to stay true to the model that's being printed at very high speed. There's just a lot of this, I'm realizing there's just a lot of it all through the additive process are these applications of AI. There's other ones we've covered, Markforged. Their blacksmith software uses AI to kind of do iterative development of processes getting the parts better and better. There's, there's production management software from Oqton that's using AI, we've covered that to kind of true in on on better and nearer to expected outcomes in the production process. We'll share links to all of these. There's one new, interesting possibility for AI I came across when I was searching around for all that we might talk about in this conversation. There's this paper we'll also link to. The lead author is Bernhard Heiden, and it covers different kinds of interlinking between AM and AI, and his paper, their paper there are several authors, is about framing the interaction between them. But, there's one possible application that the paper cited and described and it has to do with distributed manufacturing. What happens when we get to the point where we fully realize distributed manufacturing, and there's this possibility of, in real time, on very short notice deciding which facility anywhere in a region anywhere in the world will produce a particular part, a particular run of parts? Well, a system like that is going to face different kinds of shipping conditions from different locations, different shipping costs, different duties for crossing different international borders, it's actually a complicated problem. What is the most efficient way to produce this particular batch of parts at this moment? And it could be that the answer is some combination of production in different sites. And AI could get better and better and better at this, at solving the problem of the cheapest, fastest, best way to produce a big batch of parts if you've got a number of roughly interchangeable additive manufacturing facilities all engaged in it.

Stephanie Hendrixson 17:48

So that's cool. So, like it's an AI dispatcher that's sending work out in the world.

Peter Zelinski 17:53

Oh, that's awesome, AI dispatcher. Absolutely. Yes, AI could get better and better and better at the distributed manufacturing dispatcher.

Stephanie Hendrixson 18:01

All right. So as you say, there's a lot. We've talked about everything from part selection all the way through distributed manufacturing, sending your parts all around the world. But I think like the elephant in the room, maybe like the thing that we haven't really talked about is design and AI's role there.

Peter Zelinski 18:17

Yeah, let's talk about that. AI's interaction with design in additive manufacturing after the break.

Jodee McElfresh 18:22

This episode of AM Radio is brought to you by Formnext Forum Austin, a new Formnext event coming to the US this summer. The conference and expo is organized by Mesago Messe Frankfurt, AMT, the Association for Manufacturing Technology, and Gardner Business Media, the publisher of Additive Manufacturing Media. Formnext Forum Austin is designed for leaders and owners of manufacturing enterprises, including companies already advancing with additive and those getting ready to adopt it. It's also for engineers engaging with additive technology and researchers who are advancing what is possible for AM to do. The conference program offers three tracks, Production, powered by The Cool Parts Show, Design for Additive Manufacturing, powered by Cimp3D, and Technology, powered by Additive Manufacturing Media. The event also includes an expo featuring AM technology, tours of local additive manufacturers and plenty of networking opportunities. And don't miss the finalists of The Cool Parts Showcase, a contest highlighting innovative 3D printed parts. We're currently taking submissions through formnextforum.com. Enter by May 30. Join Additive Manufacturing Media for Formnext Forum August 28 through the 30 in Austin, Texas. Find more information about exhibiting, attending or sponsoring this event at formnextforum.com.

Peter Zelinski 19:48

Welcome back, I'm Pete Zelinski. I'm talking with Stephanie Hendrixson about artificial intelligence and its connection to additive manufacturing. In the first half of the show, we talked through, or at least mentioned, various different places in the additive manufacturing sequence and process where artificial intelligence is finding applicability. Stephanie, at the end of that conversation, you mentioned design, and you even described it as the elephant in the room. I really want to talk about that. Because this thing that has been affecting and shaping additive manufacturing all along, is the design perspective needed to use it effectively and is starting to feel like artificial intelligence has something to say to that. Would you start talking about that?

Stephanie Hendrixson 20:43

Yeah. So this is something I've been thinking about for a while, actually, I just recently had a conversation with somebody and they asked the question, you know, aren't we all going to have 3D printers in our kitchen someday? And like, my answer to that continues to be no, because I think that designing a part is important and challenging skill set. And then design for additive manufacturing on top of that is another important and challenging skill set. But I think, you know, maybe with artificial intelligence, like maybe this is a way that we do get to a more democratized and a more accessible version of design. So if that happens, Nicolas, I will eat my words, like I said I would. But I've been thinking about this for a couple of years now. I had this conversation last year and wrote this article about a company called Spokbee. And Spokbee is one of these platforms where you can create a design, you can list it for sale, people buy it, and then they will handle all of the the manufacturing and the shipping and all of this stuff. But in my conversation with the founder of that company, Matt Cameron, he said something about design being a hurdle to 3D printing and like all of the promise that 3D printing can bring, because the average person doesn't have the design skill to make something that is going to be 3D printable. Like, that is, again, it's a skill set. It's something that you have to learn and practice and get good at. And so Spokbee's answer to this is to offer parametric design options. So as designers are uploading their, their products, they can set different parameters. Like, if you're listing a table for sale, you can allow the users to adjust the height of the table, maybe change it from three legs to four legs, or if you're selling something like a coat hook, and there's three hooks on the device already, you could let the users add three or four or you know, however many hooks that they want. And these are things that are programmed in, and that's sort of their like in between, it's not really giving consumers total control over the design. And this is not AI at all, it's just a way of addressing this, this issue that there are so many things that 3D printing can do that just aren't accessible without those design skills. But, now we are getting to a point potentially with AI where that might not be the case anymore.

Peter Zelinski 22:50

So, the first half of the show was concrete, we were citing specific examples. And I feel like we're gonna get more speculative now with this part of the conversation because we can start to see how this problem could be addressed. So I'm thinking of the AI utility Dall-E, which uses conversational inputs to create 2D drawings, to create 2D art, and you're describing Spokbee, how it's already possible to interactively choose among different parameters to modify an existing design. It's not too hard to visualize a bridge from something like Dall-E to something like Spokbee. To the sense of maybe you could say something like, I want a table that is three feet long and eight inches wide, and it is such and such height, and it's got legs at these different distances from the edges. And the AI potentially could know tables need certain things like flat surfaces and parallelism to the floor and, and legs that are all the same length. And it is difficult to imagine how conversationally we could describe something like a bracket that needs the fastening points to land at very specific places and needs to to hold a such and such a load under such and such a condition that much is hard to see. But some of the more bespoke things that we might want, it's becoming nearer and nearer to see how AI might allow us to have those things, get the design without any DFAM skills, let alone design skills whatsoever.

Stephanie Hendrixson 24:49

Yeah, and I think where there are hints of how this might play out already. So, OpenAI, the force behind ChatGPT has this other tool that they're working on called Point-E, and it's for generating 3D models. So, you could start with a 2D image, or you could just start with conversational text like describing that table with words. And it would try to create a point cloud based on what information you've given it. I've seen a couple of examples of this. I don't think it's publicly available yet. But you can find some some images and things, we'll link to an article about this. And sometimes it works out kind of weird. And sometimes it works out pretty well. And they are working on an additional AI tool that could take those point clouds and convert them into meshes, which puts us pretty close to the neighborhood of being able to use these as actual models and 3D print them. I think they're thinking of it more for like VR, virtual reality and video game type design environments, but if you are already thinking in three dimensions, like it's not that much of a leap to think about how you might end up with a 3D printed object at the end of this. There are a couple of other companies like Nvidia and Google that are working on different tools that can do these types of things as well. I think they're still pretty clunky at this point, but there is a foundation for how that could happen in the future.

Peter Zelinski 26:06

So imagining what that might mean. So I think that still doesn't get you the 3D printer in your closet or in your kitchen. Right. But because, for example, your material is still going to be the constraint. And even if you are conversationally describing a 3D form, what properties and possibilities the material brings to it is something that just a normal person is not going to have that, that expertise. But here's what I could see, the direction I think we're already seeing for manufacturing service providers offering additive manufacturing is they tend to commit to materials, particular machines are just left dedicated to materials, which has the practical effect of particular companies really only, only specialize in a particular set of materials, and they're not immediately equipped to provide others. So this conversational description of this object that I want, I could say, Make me a table like this, this, this. Make me a bracket like this, this this. That could be produced by such and such company over here. And the AI would also know what material set that company is capable of, and could give a design that, that utilizes the properties of the materials that are available for that manufacturer where you want to have it made.

Stephanie Hendrixson 27:37

Yeah, so like sort of a specialized AI that, that knows certain parameters, certain choices like that in advance, to help make better decisions about how to design and how to make this part. I want to give an example that actually comes from the CNC machining world. So there is this company that I've been talking to in Washington State, they're called 3DX Industries, they're a metal parts producer, they have various machining technologies, they also have metal binder jetting. And so like they're thinking about how to transition parts from one to the other, and all that sort of thing. But they're really interested in AI as a way of helping with design, helping you get to the part faster. And they've played around with it not so much for 3D printing, but actually for creating G code. So it turns out, like if you go to ChatGPT and ask it to make you the G code program to drill a hole, it will spit it back out to you. And it'll say, you know, this assumes that the hole is 10 millimeters in diameter, it's 10 millimeters deep. And then you can sort of, you know, have a conversation with ChatGPT to say, Well, no, I actually need the hole to be larger or smaller, or can you make it two or three holes and arrange them in such and such way? I'm not sure what the limit is on that. But I do know that 3DX Industries has actually run some programs that they've generated through ChatGPT, it's really simple stuff, it's drilling holes, I actually saw a video of one where they asked it to cut the number three, the letter D and the letter X with a FANUC ROBODRILL and like the machine actually did it. And so they see a lot of promise in this for just getting to like that more conversational programming, and maybe some other promises down the road.

So the president Roger Janssen was talking about how, like a lot of companies like they're strapped for employees, and if a skilled machinist leaves like that kind of puts them in a difficult position. They had that situation recently where he had to step in and do some of the programming, which, he's an experienced machinist. Like, he knows how to think about these things and how to do this, but the challenge he ran up against is that the CAM software has advanced so far since the last time he was really in the weeds doing this type of programming. And so he said, like, I can look at this design, I can look at this part and know exactly how to get there. But translating what I know into the computer to explain how to do it through the software is kind of a hurdle. And so if you could get to a more conversational way of programming where he could say in words, what operations need to happen and in what order and with what type of cutting tools that would maybe be a faster way to get to that part. But it also could be a way of capturing that knowledge that more experienced operators, more experienced designers, more experienced machinists have and helping make that easier for other users down the road.

Peter Zelinski 30:17

Yeah, that's really interesting. So that's machining, it connects right to what we're talking about, though. Knowing what I know about machine shops and machined part programming, I bet almost any programmer would look at that and say, there's something inefficient about the program that that AI developed. In the same way you and I, Stephanie are looking at writing the ChatGPT is doing and seeing things missing from that or, or inaccuracies in it. But if a, if a G code program is a little bit inefficient, it's okay, if it provides a more effective way to get you to the end result you're hoping for. I guess where I want to take that is this. We're talking about design, and we're talking about faster ways to get to the thing we think that we want or, or, or ways to get to the thing we think we want that have less knowledge requirement to them or less skill requirement as a point of entry. There's also this design possibility in additive that relates to getting to a thing we don't even know that we want because it wasn't possible before. I'm thinking of company, we've covered Material Resources, Inc. They are in the Dayton area. And this company's pursuit is all about metal microstructure, and manipulating it, controlling it on a microscopic level, to get specifically the the material capability and performance outcomes that you want. We haven't had a way before to get finely tuned micro structures. And we still don't know exactly all of the different process parameters to tune all of the different knobs to dial in to get exactly the microstructure we want. But Material Resources is using AI to get to this to find these correlations. And the promise that they're getting to is, say, I need fatigue strength on a part, in, on a particular surface, in a particular region of the part. Let me just build in the fatigue resistance right there, but then make all of the rest of the component really easy to 3D print fast, because I don't need such a precisely controlled microstructure in those areas. Like we could do things like that, boy, and then if you again, we're being very speculative here. But if you connect that to the kind of conversational formatting of the design that we're describing, what if I could say that, yeah, make me this bracket out of titanium and this hole here at the, at the, at the end of the longest flange? I need a whole lot of creep resistance right there. So hey, just go give me that.

Stephanie Hendrixson 33:18

Yeah, so like outsourcing the granular design, but also like outsourcing the granular decision making. So, how do you make that feature stand up to whatever load you've given it? And then how do you also make the rest of the part like simple and fast and easy to 3D print? That is something that like a human could spend days on, and a computer could figure out like that. So, sort of the next evolution of this line of thinking, or maybe just another avenue for AI and 3D printing, I think, is to improve designs over time based on the outcome. So, I'm thinking of an example, this is an article that is on our site now, about ActivArmor. This is a company in Colorado, it's a startup, it's just a couple of employees, but they produce casts and splints, 3D printed ABS, typically with just like an FDM-style desktop printer. And these casts and splints are being used in all kinds of ways right now, often by pro athletes, often by kids. The advantage is they are really durable, they're waterproof, they're, you know, something you could wear in the shower, like that sort of thing. But the next evolution for this company, they see potential in AI to take a patient's diagnosis, take the design of the device that they received, and then match that back to how their injury healed. And if you can sort of create like a closed loop around that you could start to learn, you know how certain features in these devices helped with healing outcomes or influenced healing outcomes to help doctors make better decisions about how to design the devices. And they see a lot of promise in this for bringing the solution to like more rural areas, to third world countries, that sort of thing. They see a lot of potential in that not just for improving patient care, but allowing doctors anywhere in the world, basically, to provide the best possible care, because it's almost like they have the knowledge of all of the orthopedic surgeons and other clinicians that came before them built into this system. They have all of these sort of, like, past cases to draw on, even if they're not aware that they're drawing on that knowledge.

Peter Zelinski 35:22

All right, there's a lot here, artificial intelligence, additive manufacturing, why are we talking about them together? I think it's because additive is this frictionless manufacturing process, or the closest one that we have, it's possible to start with nothing, just a machine that's ready to go and 3D print the part that you have in mind. And there aren't other manufacturing processes that look like that. CNC machining is probably the closest, but even there, you're not starting from nothing you need to know from the beginning, what is the stock size that you're starting with and what tools are in the magazine, you need to know all that. You don't need to know things like that going in with additive, frictionless, postprocessing, still needed, won't get to do it in your kitchen still need a manufacturing provider, but the starting point doesn't have that friction. And with artificial intelligence. Now we're seeing how that is, is manifesting as this frictionless information system. And so it's pretty easy to see how they can grow together and how one can help the other, to the extent that I feel like the the further advance of artificial intelligence in manufacturing is inherently further advance for additive manufacturing. I guess here's, here's the other quick thing I want to say. It's hard for science fiction to predict the future, how technology will be used. It's hard because science fiction always takes technologies we start to recognize today and just projects them a straight line into the future. And so there were writers that predicted something like the internet, and there were writers that predicted something like easy handheld, portable communications. But what actually happened is the internet and portable communication devices grew together and mushed into one thing, and that's what changed our world. The thing I think I can't quite imagine is what is manufacturing going to look like when artificial intelligence and additive manufacturing go all the way toward mushing into one thing.

Stephanie Hendrixson 37:35

So we've spent this whole podcast episode talking about the ways that AI and AM are interconnecting already and like the ways that they're, they're touching each other. But there is going to be probably more of that convergence, like more influence and probably more rapid advance for both of those things in the future.

Peter Zelinski 37:52

I hope so. It's exciting. It hurts my head a little bit, but I hope so.

Stephanie Hendrixson 37:57

All right, so I think we should leave it here for this episode, we will drop links to everything that we talked about in the show notes. Also, if you have not yet subscribed we have a new newsletter called The BuildUp where we're doing original writing about additive manufacturing, 3D printing all of this stuff. You can subscribe to that on additivemanufacturing.media. And if you're looking for other podcasts about manufacturing, Pete actually appears in a podcast from our sister brand called Made in the USA. You can find that at mmsonline.com.

Peter Zelinski 38:27

And if you like this show, please subscribe or follow. Leave us a comment, leave us a five-star rating, it really help.s Thank you for listening.

Stephanie Hendrixson 38:35

AM Radio is recorded with help from Austin Grogan. The show is edited by Jodee McElfresh and me, Stephanie Hendrixson. Our artwork is by Kate Bilberry Schrand. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in the Queen City, Cincinnati, Ohio. I'm Stephanie Hendrixson. Thanks for listening.

Related Content

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreMPI Launches AI Project to Create Material Reuse Management Tool for Metal 3D Printing

MPI is working with Additive Manufacturing Solutions and AMFG to create a versatile, commercial predictive material reuse management tool that will enable additive manufacturing to expand by introducing greater cost efficiencies.

Read MoreEOS, Hyperganic Partnership to Elevate Space Components

Integration of Hyperganic Core, an AI-powered engineering software platform, with EOS’ digital additive manufacturing solutions aims to advance the space propulsion field.

Read MoreAI-Assisted 3D Slicing Software Simplifies Dental 3D Printing Process

The software simplifies the 3D printing process so users don’t need special design training.

Read MoreRead Next

In Manufacturing, AI Is Clumsy Until It Is Invisible

Artificial intelligence is finding wide use in advancing additive manufacturing. We have seen a hint at how far this might go.

Read MoreWhy Self-Supervised Deep Learning May Be Additive Manufacturing's AI Solution

In collaboration with equipment supplier EOS, artificial intelligence experts at NNAISENSE have created a self-taught “deep digital twin” to advance additive manufacturing, starting with direct metal laser sintering of titanium.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More