Mantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.

Mantle has begun shipping the production version of its 3D-printing-enabled system for rapidly producing steel injection mold tooling. Systems in use so far have been for beta testing, which is now complete. On a recent visit to the company’s San Francisco headquarters and production facility, I spoke with company co-founder Ted Sorom and other team members about the acceptance of the company’s system so far, and the role it is likely to play for plastics processors and moldmakers.

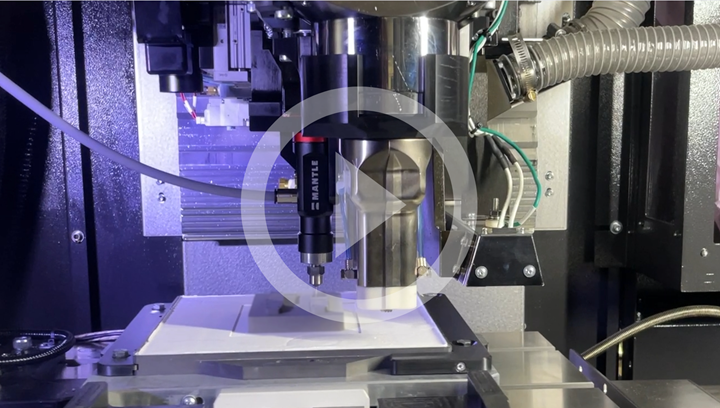

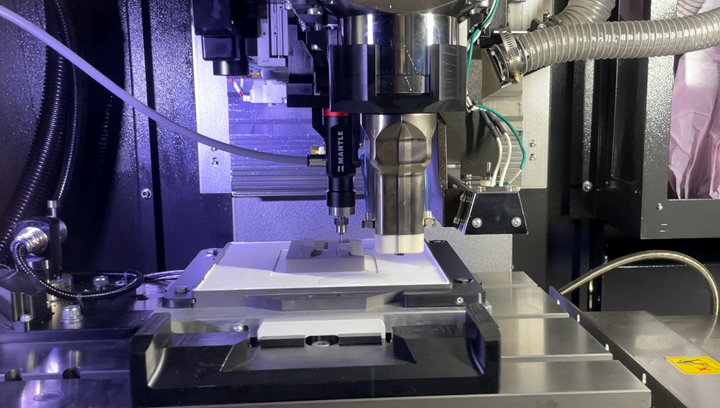

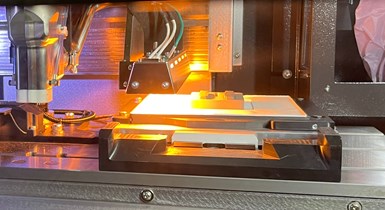

The Mantle process rapidly 3D prints and shapes mold tooling, made from steel, using a machine that is a modified CNC machining center. Machines such as this one are now shipping from the company's San Francisco production facility.

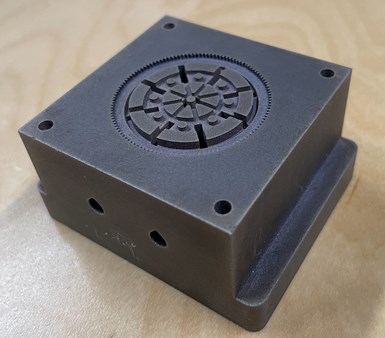

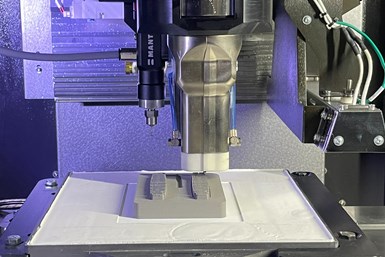

An example of a mold tool made from the Mantle process. The process produces mold tooling suitable for production-scale injection molding of plastic parts. Precise details are possible through CNC “shaping” cuts that complement the 3D printing.

One significant finding related to the system’s acceptance so far is this: Sorom says he thought mold price would be the driving factor. The company’s “TrueShape” process competes against conventional moldmaking on both cost and time — but time savings is proving to be more significant for driving adoption and potentially transforming how tooling is developed.

Mantle’s TrueShape is essentially a new and different method for making plastic injection molds. The process works this way: Metal paste developed by Mantle is 3D printed and CNC machined in a single operation, and then through controlled sintering becomes a fully dense steel mold core or cavity, in material equivalent to H13 or P20. Rough milling and EDM are avoided in this process, as is drilling of the cooling lines, which in TrueShape can easily be 3D printed conformal to the tool geometry. Tool performance is equivalent to a mold made traditionally (one molder, Tessy Plastics, has taken a TrueShape mold past 1.65 million cycles), but the pacing is much faster: Printing and sintering of a core and cavity take just two to three days, compared to the several weeks of lead time more commonly associated with injection molds. The system consists of machine, software, furnace and material — all supplied by the company — and this video offers more detail about the operation of the Mantle moldmaking process.

Ted Sorom (at right) is Mantle’s co-founder. He is seen here with VP of manufacturing Mark Sloan. Sorom has found that cost saving has not been the main driver of interest in the company’s technology. OEMs have the cost of mold tooling factored in, he says, but they have struggled with growing lead times for this tooling. Allowing tooling to be obtained quickly facilitates part and process validation. Photo: Mantle.

At the company’s headquarters, I met with Sorom along with chief commercial officer Paul DiLaura and director of marketing Ethan Rejto. All described what they see as an important differentiator for the company: its single focus. Parts made through the Mantle process are real tool steel, and much of the IP is in the way the paste ingredients plus the steps in the sintering cycle operate to realize this material. And while there are various potential applications for a 3D-printing-plus-CNC process that realizes a geometrically precise steel part, moldmaking is the most promising, and it is the only application the company is pursuing. Yet even serving this one market leaves plenty of room for lessons to be learned — such as the often second-place importance of cost.

The starting point for the Mantle process is metal in a paste form. This state makes 3D printing and shaping easy. Precision is maintained through a sintering step calibrated to the different components of the material. The final result is a tool in H13 or P20 tool steel. Our companion video discusses the metal paste in more detail.

Production Tool, Prototype Time

Sorom says, “For large OEMs, the cost of tooling is already factored in. They expect it.” By contrast, the lead time for molds is a factor increasingly slipping out of their control, affecting how quickly they can adapt and innovate. Mantle’s process answers the mold lead time challenge by providing a production tool so quickly as to eliminate the need for a prototype tool (that is, a temporary tool machined from aluminum or 3D printed in polymer) by eliminating the distinction between production and prototype tooling.

A drying pass after each layer prepares the component being printed for CNC shaping steps.

DiLaura explains the consequence: “We offer time savings through faster validation,” he says, whether that is validating a fully new design or a design change. Where there is a validation requirement for plastic parts, even a small design change might introduce a major delay. DiLaura quotes a beta user, Nicolet Plastics, saying one of its leaders noted this difference with the Mantle system: “It lets us get a production tool in prototype time.” This enables validation of both design and process simultaneously. The fast moldmaking “de-risks production,” DiLaura says. “If the part design works, then you begin production with the same tool.”

Mantle does not refer to the cutting step as machining, because it is not performed in hard state of the metal. CNC "shaping" is performed to ensure precision after about once every 10 3D printing layers. The consistency of the material at this moment is something like rigid foam, so these fine material removal passes are fast.

The potential for cost savings then enters in if there is a chance for performance improvement over a standard tool, Mantle says. For example, beta user Westminster Tool brought the improved molding performance of conformal cooling to a customer’s part without the conformal channels adding to the cost of the mold.

Sintering is also an essential part of the process. A furnace with preprogrammed sintering routines tailored to the metal paste is part of the system the company provides.

Sorom notes the time to make a mold with this system is not only shorter, but more predictable. This led to another discovery: TrueShape is also an estimating tool. “We know exact time and material use,” he says. “Job quoting is much easier” — an advantage pointed out to Mantle by early users.

Yet this win speaks to something larger, related to the knowledge work in plastics and the limited talent pool available for this work. Among other things, Mantle sees its system as poised to provide a response to plastics manufacturers’ skills shortages.

Toolmakers Needed, But Now Can Do More

The Mantle system offers a different method of making molds, but not everything is different. Toolmakers are, of course, still required. Plastics engineers as well. Someone has to design the mold; someone has to finish, fit and build the mold after the core and cavity are made. TrueShape’s solution applies to steps in between. It can eliminate roughing, EDM, prototyping — not people. But as DiLaura points out, it can allow those people to do more.

A clear polymer model of the mold shows the conformal cooling channels printed into this tool. Conformal cooling is not the principal driver for why this moldmaking system is applied, Mantle notes. However, it is an option: Cooling channels are printed into the mold, and they can be made conformal rather than straight.

Nicolet Plastics is an example of a company able to benefit from this, he says. The injection molder relies on an in-house toolmaking department with experienced team members. Any retirements from this team would likely cause in-house toolmaking capacity to decline, due to the potential difficulty of finding a suitable replacement toolmaker. Streamlining the process — through easier quoting for engineering and fewer steps in moldmaking — amplifies the capability of knowledgeable people by freeing some of their attention and time.

That benefit, when multiplied by every mold shop and plastics processor, represents a large opportunity — and a worthy reason to stay focused on moldmaking, Sorom says, particularly as the process advances. As our video describing the TrueShape process points out, there is still ample room for improvement: The system does not yet even take full advantage of the potential feed rate of the machining center platform on which its 3D printing and material shaping machine is built. Potential such as this is being pursued, resulting in advances that can be pushed out to machines in the field via software update. “Because of our focus on one application,” Sorom says — that is, the focus on moldmaking — “every improvement we make will benefit every user.”

Related Content

3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreHow AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read More3D Printed End of Arm Tooling Aids Automation

Frustrations with traditional end of arm tooling led Richard Savage to start 3D printing custom versions for injection molding applications, eventually founding a company to fill this niche.

Read MoreRead Next

3 Types of 3D Printed Tooling for Injection Molding: AM Radio #16A

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreMold Shop Evaluates Mantle Process for 3D Printing Steel Injection Molds

According to tests performed by Westminster Tool, Mantle’s 3D printing materials behave similarly to traditional steels and hold up well during molding, making them easy to incorporate into existing moldmaking processes.

Read More