Additive manufacturing (AM) is the technology disrupting manufacturing today, but a generation or so ago, the technology playing that role was composites. Like additive, the use of fiber-reinforced polymer composite materials brings opportunities for lightweighting, transitioning from metal to polymer and consolidating assembly. Also like additive, composites manufacturing entails building parts in layers — though in the case of composites this generally involves building onto a custom tool.

Today, composites have won their place in various applications. They provide the established material and method for manufacturing a variety of valuable components, most notably major aircraft parts. Yet the application of composites is still advancing, and today that advance is being accelerated by 3D printing. The use of AM offers a way to make parts out of composites without the need for a tool, and at the same time, AM brings new options to composites-industry tooling. Thus, while composites in one sense remain disruptive, in other sense, composites are being disrupted.

For a perspective on this, I spoke with Jeff Sloan, editor-in-chief of CompositesWorld. Sloan is an observer of composites technology the way the writers for this site are observers of AM. And because of the interplay between these two technologies, often we are looking at the same things from different perspectives. What follows is a conversation exploring his perspective.

Additive Manufacturing: Jeff, a basic question to start: What do you mean by “composites”? Technically, the term describes many different materials. But when you cover “composites,” you mean something specific.

Jeff Sloan, CompositesWorld: Yes. By “composite,” we generally mean a thermoset or thermoplastic polymer matrix material that is reinforced with continuous or discontinuous fibers, and those fibers typically are carbon fiber; glass fiber; or natural fibers such as jute, flax, aramid or basalt fiber.

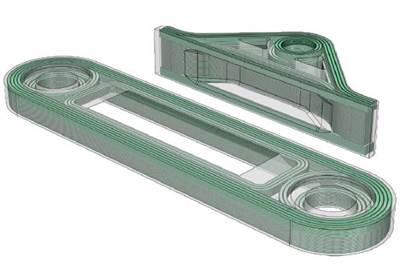

Here is a case of composites manufacturing and additive manufacturing in tandem. This system from Electroimpact first 3D prints the tool via fused filament fabrication (FFF), then builds the composite part onto that tool using automated fiber placement (AFP). Photo credit: Electroimpact.

The most valuable end market for our audience is aerospace. Polymer composite materials are used in a variety of parts and structures ranging from fuselage skins, stringers and frames; wing structures including wing skins, spars and stringers; and tail structures; and also in more discrete parts like window surrounds, interior parts including luggage storage bins and inside bulkheads. The walls within the aircraft typically are also made with composites. So that’s the biggest end market, the highest value end market for us. Meanwhile, the largest end market by volume of materials is the wind blade industry. If you think about a wind turbine sitting out on a prairie and turning — those wind blades are made entirely out of composites. And those composites make those wind blades possible. You couldn’t make them with another material.

AM: How does additive manufacturing bring something new to composites?

Jeff Sloan reports on the composites industry as the editor-in-chief of CompositesWorld, a sister brand to Additive Manufacturing. Sloan has served in this role since 2006.

Sloan: When we talk about additive in the context of composites, I’m talking about 3D printing with a material that has fiber reinforcement, and the gold standard for us is continuous fiber reinforcement. What additive manufacturing does, for our audience and their applications, is to provide a technology that allows more efficient and faster fabrication of parts that until a few years ago may not have been economically feasible using current composites manufacturing technologies. When you think about discrete parts or low-volume manufacturing, those parts might have been impossible to make with existing composites manufacturing. Modern AM makes them possible. Then, with the use of continuous fiber in additive, you’re bringing in an element of strength and stiffness that is sort of a next level in terms of part capability and applications.

AM: Give examples. What are some of the kinds of parts that are now candidates for manufacturing with polymer composites, or maybe become easier to manufacture with composites, thanks to AM?

Sloan: I think about the variety of brackets and fasteners that are used a lot in the aerospace industry — particularly in some of the aerostructures I mentioned. For instance, when you’re assembling an aircraft, you have a fuselage skin, and then within the skin you’ve got a series of frames and stringers. If you think about it as a human body, the frames and stringers would be analogous to the rib cage and the fuselage would be the skin over the rib cage.

I think we are going to see more and more positive collisions between additive manufacturing and composites manufacturing processes

Under current manufacturing regimes, you need a mechanical fastener to attach frames and structures to the fuselage skin. That’s currently being done with a variety of complex brackets and fasteners and other hardware made using traditional composites manufacturing — compression molding — and I can see a future where that might be more efficiently done with additive manufacturing, depending upon volumes and material requirements.

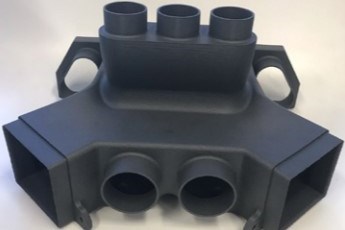

AM makes composites increasingly practical for parts that are smaller, more intricate and made in low volumes. This example from the composites material producer Hexcel is a 3D printed unmanned aerial vehicle (UAV) component made using the company's "HexAM" composites additive manufacturing process. Photo credit: Hexcel.

AM: When you talk about low-volume, somewhat complex parts, I imagine components that would likely be machined metal parts today. Do you see composites increasingly replacing metal, and 3D printing being a significant enabler to that?

Sloan: Composites replacing metal parts has been the modus operandi of the composites industry for about 50 years. So that is the established mindset a lot of our audience is already in, and there’s a natural extension of that into composites additive manufacturing. The industry is always looking for opportunities to apply the benefits that composites offer in a way that can displace the legacy material.

AM: Conventional composites manufacturing processes rely on tooling. Additive manufacturing for composite parts offers an option that is free of tooling, but 3D printing could be used to make the tool as well, and that tool may or may not itself be a composite material. What are the changing possibilities for tooling that come because of AM?

Sloan: The tooling world is complex for composites manufacturing. There are a couple of possible solutions that could help make tooling manufacturing more efficient, less expensive and more robust.

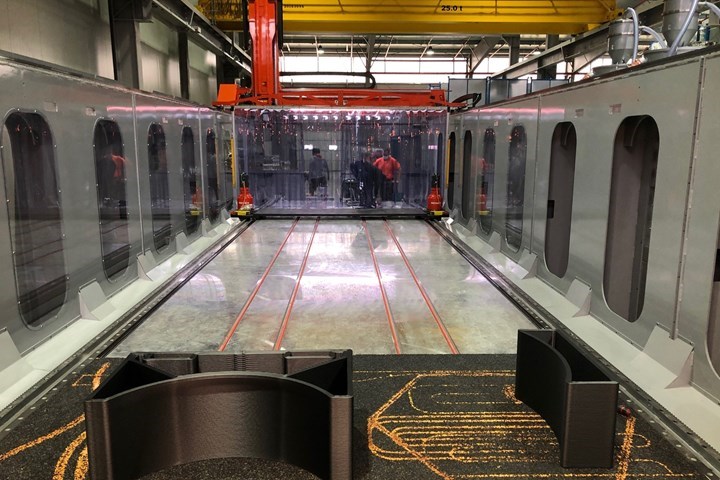

Another supplier of materials to the composites industry, Airtech, recently invested in this large-format additive manufacturing machine from Thermwood. Through 3D printing, composite material can be used to build tooling for composites, so Airtech has expanded its offerings into this service.

The first is the manufacture of large-format tools using (typically) a thermoplastic material reinforced with discontinuous carbon fiber in a system like those provided by Cincinnati Incorporated or Thermwood. You use those to build up a tool layer by layer. What you end up with is a tooling structure that then needs to be finished in some way. It needs to be sealed to make it vacuum-compliant, because a lot of composites manufacturing processes depend upon pulling a vacuum on the tool.

There are some challenges here as you build those layers up. The biggest is two-layer adhesion, or Z-direction strength. It’s critical to achieve strength equal in the Z direction to the X and Y directions, which means you have to have some mechanical interaction or mechanical interlocking between layers as you build up this tool. The other challenge with tooling made additively is the coefficient of thermal expansion (CTE). If you’re using a composite tool to make a composite part, you need that composite tool to have similar CTE to the material that is being molded. If you don’t, you run the risk of the tool distorting in some way during the manufacturing process that could be detrimental to the part — it may affect the part’s dimensions, break the part or cause the part to become stuck on the tool. Managing that CTE is critical, but there are ways to do that, and we’ve been covering this.

Of course, the other solution is to make a metal tool via additive manufacturing. In aerospace, I think this is going to become a highly attractive option. One of the most widely used tooling materials in aerospace manufacturing is Invar, and Invar is expensive, heavy and difficult to work with. But there’s some work being done that uses Invar as a feedstock material within an additive manufacturing process. Invar’s CTE is very similar to that of carbon fiber, so it should be a forgiving material for AM.

AM: You spoke of AM expanding the range of parts that become viable for composites. How does AM enter the established composites industry? What impact or inroads do you see it having there — is tooling the way this happens?

Sloan: Composites technology already looks a lot like AM, and that’s important in thinking about this question. One of the most direct analogs is automated fiber placement or AFP. AFP was invented in in the late 70s or early 80s, and is basically the application of a tape or a “tow” that can be anywhere from a quarter-inch to a half-inch wide. It’s typically carbon fiber and often pre-impregnated (“prepregged”) with a thermoset material like epoxy. A robot lays the tape onto a tool, then applies it to the tool and cuts it. And then it’s laid down again — we cut in courses. You can see a lot of parallels to AM. So there is a natural fit already.

What I think we’re going to see is … AM providing design flexibility and manufacturing flexibility that doesn’t exist today.

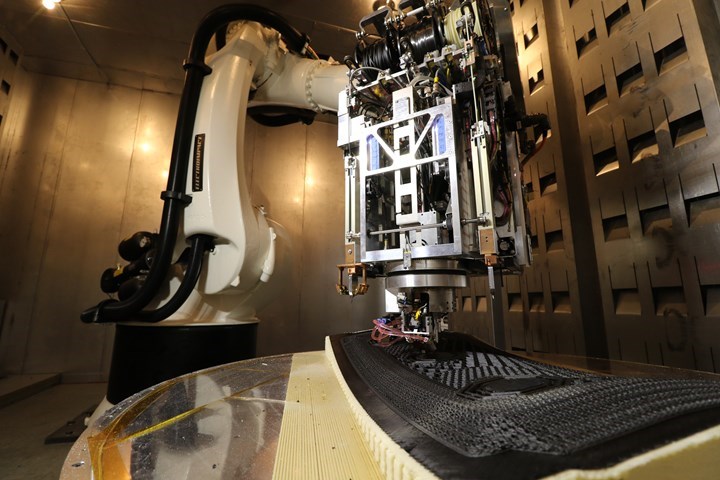

One of the most active AFP developers in the composites industry is Electroimpact, a supplier to Boeing that developed a lot of technology to apply composites to the 787 aircraft. Electroimpact recently introduced its own additive manufacturing system that literally combines AM with AFP. And it does it with a two-part system that applies additive manufacturing to build what you might call a mandrel. It then uses AFP or an AFP-like system to wind carbon fiber tapes around that mandrel, the tool, to build a composite part. The mandrel can be 3D printed to whatever shape you want, and then after winding the carbon fiber around that, the mandrel could be washed out or removed in some way.

It’s a system I think signals where some of this technology is heading, and I think we are going to see more and more positive collisions between additive manufacturing and composites manufacturing processes.

AM: Are there cases in which a part is being made through composites today, through a conventional composites manufacturing approach, where 3D printing offers a better way to make that part?

Sloan: I don’t think there’s an established composites manufacturing process that is at risk of being wholly displaced. But I do think what we will see is that composites AM will be increasingly integrated into the composites manufacturing toolkit, and AM will integrate more with existing composites manufacturing processes to add functionality.

For example, there are some new AM materials out there with integrated fibers for conductivity. Hexcel just came out with a 3D-printable material that does this; you can integrate fibers for health monitoring of the part. So, you might have a larger composite structure that’s made with traditional composites manufacturing processes, but it integrates smaller discrete parts of a specialized material or functionality like this that is most effectively made via additive manufacturing.

The C-FREX exoskeleton from Uchida was developed to provide mobility to people with spinal cord injuries. Composites provide for a lightweight design. Most parts are made through conventional composites processes, but 3D printing is used for components that are tailored to the individual. Photo credit: Uchida Carbon Composite Technology.

We did a story recently on the development of a carbon-fiber exoskeleton that is designed to help people with limited mobility or some paralysis to walk, and this is a large carbon-fiber structure mostly made with traditional processes. But there are certain parts of this exoskeleton that must be customized for the size, fit and body type of the person wearing the exoskeleton. That customization is provided by additive manufacturing. Combining the larger structure with these discrete parts allowed customization of the larger structure for the user.

What I think we’re going to see is more and more effort being made to apply composites additive manufacturing in a way that complements the existing system or extends or applies existing established composites manufacturing processes in a way they just couldn’t go before. That is, AM providing design flexibility and manufacturing flexibility that doesn’t exist today. This is one of the fastest evolving, most dynamic parts of our industry — we’re paying close attention to this and eager to see how it evolves.

Related Content

Can Additive Manufacturing Compete With Conventional Manufacturing on Cost?

When it can, says Evolve, the design advantages of AM find their way in. The company is beginning to ship its high-speed AM system for polymer part production.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreHow AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read MoreRead Next

Fiber-Reinforced 3D Printing Expands Control, Applications for Composites

9T Labs’ deposition process places continuous carbon fiber only where necessary to save material, reduce waste, and more precisely control the structure of preform composites.

Read MoreThermwood’s Vertical Layer Printing Turns AM on Its Side

Vertical Layer Printing (VLP) 3D prints layers perpendicular to the floor, extending Z height to the length of the print bed — as long as 40 feet.

Read More3D-Printed Tooling Offers Durability for Precast Concrete

As an alternative to wooden tooling, 3D-printed forms for precast concrete are proving to be more durable and better able to support a large-scale renovation project.

Read More