The advantages of metal 3D printing for moldmaking are clear — it can save moldmaking lead time while also producing molds that (through features like conformal cooling) perform better than those made by machining. These potential benefits led Westminster Tool to begin exploring various metal AM technologies in 2017 to use in its moldmaking work for the medical and aerospace industries. But, as manufacturing engineer Eddie Graff explained in a presentation at Amerimold 2021, the shop kept running into four shortcomings:

- Tolerances. Many of the systems the shop considered couldn’t hold tight enough tolerances. This would drive up postprocessing costs, making 3D printing more expensive than machining.

- Stability, or the ability to hold flatness. Molds need to be able to hold their shape during postprocessing, but Westminster found that internal stresses in 3D printed molds were causing movement, making them unable to hold flatness tolerances.

- Porosity. Porous materials can cause undercuts in the mold, preventing plastic parts from ejecting.

- Cost. The cost to buy metal 3D printing capacity in the form of laser powder bed fusion can be on the order of $1 million, out of the reach of an independent mold shop such as Westminster Tool.

In 2019, the shop entered a partnership with Mantle, a 3D printing startup whose system is specifically designed for moldmakers. Mantle’s TrueShape technology is a hybrid process that combines a milling machine base with a print head that extrudes a metal paste. The paste holds its shape well enough that it can print fine details. For use in its machine, Mantle has developed two materials, a P20 equivalent called P2X, and an H13 equivalent.

As part of the partnership, Westminster worked on two R&D projects using Mantle’s technology. The first involved material testing to determine the post-print machinability and stability of cavities produced using Mantle’s materials, and compare their performance to traditional steels. The second project studied the feasibility of using a 3D printed core in a mold, including use of conformal cooling channels, tolerances on complex geometries and whether the cavities would hold up through a few hundred molding cycles.

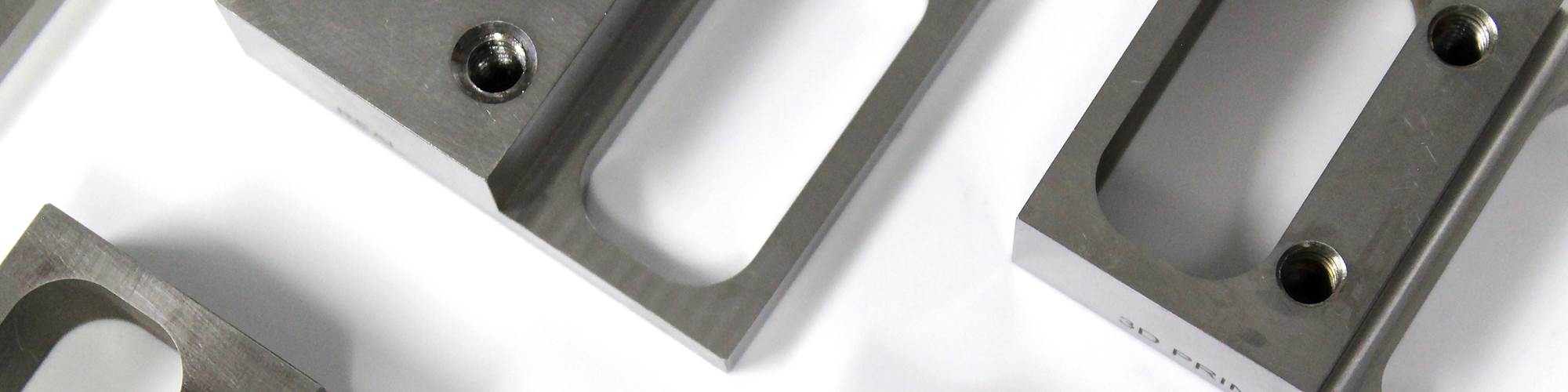

Westminster Tool tested the machinability of Mantle’s 3D printed P2X material by designing a test block with thread-milled and hand-tapped holes, thin-wall pockets made with wire EDM, hard-milled ball runners and primary and secondary vents, and a soft-milled flange. When shop ran the P2X block through these processes using P20 parameters, it found that the P2X performed comparably to P20. Photo Credit: Westminster Tool

For material stability, Westminster wanted to know if it could make the material flat, square and parallel. It tested this by performing grinding operations on the material and then checking for cupping and warpage. The tests were successful — the material held tolerances of 0.0001 inch after traditional grinding and less than 0.0001 inch after wet grinding. The shop also machined thin-walled geometries that were likely to warp due to internal stresses. These results showed that the blocks of material held a flatness of 0.0007 inch or better on all sides. According to Graff, this was the first time the shop had seen a 3D printed material whose stability was comparable to true steel, allowing it to predict part movement and achieve the tolerances required in moldmaking.

Next, Westminster designed a test to assess the material’s machinability. This was important because the shop wanted to ensure that the 3D printed parts would fit into its existing machining processes. It designed a test block that included features and geometries common in moldmaking: thread-milled and hand-tapped holes, thin-wall pockets made with wire EDM, hard-milled ball runners and primary and secondary vents, and a soft-milled flange. Then the shop ran a P2X block through these processes using typical P20 parameters. Results showed that the P2X block’s performance was comparable to P20 without requiring special parameters or attention. Graff notes that many of the machine operators said they would not have been able to tell that the block wasn’t traditional P20 steel.

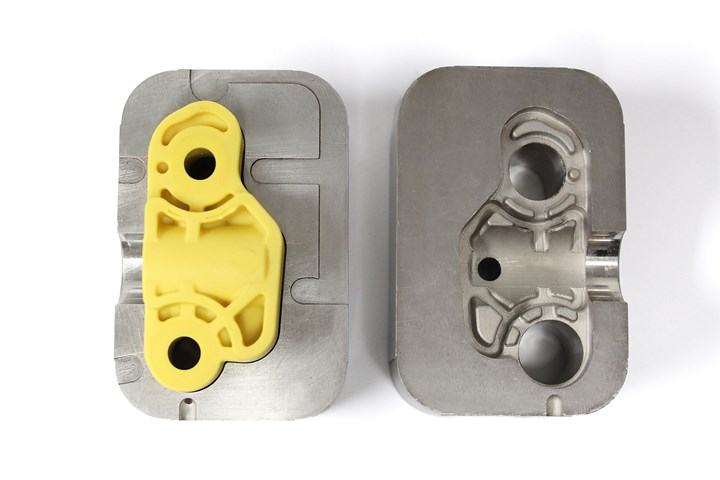

Westminster also tested a 3D printed cavity. The 3D printer’s tolerances reduced postprocessing time by 20 hours, while the addition of conformal cooling channels reduced molding cycle times by 10%.

Photo Credit: Westminster Tool

The second project was a core replacement test to study how a 3D printed cavity performed in a mold. For this test, Mantle printed a 3 × 3 × 2 inch P2X cavity. The cavity’s design was chosen to be complex, but similar to the work Westminster expects to make on Mantle’s machines. After printing, the shop did a full CMM inspection on the cavity, which showed that tolerances were within ±0.002 inch. Graff adds that since the initial trial two years ago, Mantle has continued to improve its tolerances. He estimates that the machine can hold tolerances of ±0.001 inch on a 3 × 3 × 2 inch block, while a 6 × 6 × 4 inch block could hold tolerances between 0.001 and 0.004 inch. These tight tolerances will reduce the need for postprocessing on 3D printed cavities. On this replacement cavity, Westminster estimates that it saved 20 hours of manufacturing time. 3D printing also enabled the addition of conformal cooling channels without added cost or lead time, which reduced molding cycle times by 10%. And after running the 3D printed cavity for a few hundred cycles, Westminster determined that it was able to withstand the temperatures and pressures of the molding process.

Westminster expects to receive Mantle’s first beta printer in early 2022. With this 3D printing technology, the shop will be able to integrate conformal cooling channels into molds without increasing cost or lead time. Reduced manufacturing costs will also enable Westminster to print mold tooling for prototyping, pilot testing and bridge applications.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreRead Next

Materials are Key to 3D Printed Injection Mold Tooling

IC3D’s combination of experience with filament production, building 3D printers and service bureau work is helping it expand the possibilities of 3D printed injection mold tooling.

Read MoreOver 1 Million End Parts Produced With Mold Made on Mantle Metal 3D Printers

Over 1 million end-use plastic parts produced using mold tooling made via the TrueShape system for making precise steel tooling rapidly using 3D printing.

Read MoreHow Flowable Metal Paste Could Deliver on 3D Printing's Promise for Mold Tooling

A new 3D printing process that shapes extruded metal paste before sintering can produce fine detail and surface finish suitable for injection mold cores and cavities with limited or no additional postprocessing.

Read More