In Casting and Molding, AM Simplifies Conventional Manufacturing

In new ways, additive processes are streamlining and enabling metal casting and plastic injection molding.

Share

There is a criticism of additive manufacturing that says AM is not easy to master, not easy to succeed with in industrial production. A fair response to that critique is this: Have you noticed how much education and experience a foundry engineer draws upon? Are you aware how much time a toolmaker requires to master the trade? Processes such as casting and molding are not easy themselves.

But here is something new: AM is getting easier, in the sense that some recent advances by AM technology providers involve systems aimed at more simply and seamlessly producing the 3D printed component as expected. And along the way, these advances are making established manufacturing processes easier as well. Various recently posted articles illustrate the point.

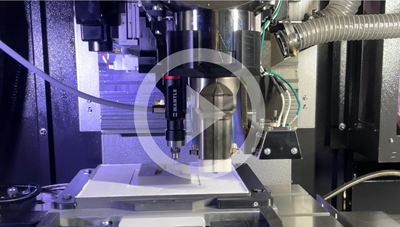

Consider Mantle. The goal of this company’s process is not a 3D printed part but a molded plastic one, because the system produces metal mold tooling. But more, the system produces mold tooling easily, using a process that avoids points of difficulty. In this process, 3D printing does what it does well, building the form, while machining also does what it does well, realizing fine tolerances, all within a sequence of operations in which the steel of the mold does not harden until all the geometry is done. Integrated software, sintering, material and 3D printing allow this sequence to produce a precise steel tool. The result: mold tooling in two to three days, using low-cost machinery including a modified standard furnace and machining center.

Of course, AM for moldmaking is not new, but the advance here is more fundamental. Previous applications of metal additive for mold tooling have emphasized conformal cooling, leveraging and justifying 3D printing through its ability to create cooling channels following the curves of the molded form. The Mantle process allows for this same advantage without needing it. This process says: Print the cooling lines as you want them, conformal or straight, and moldmaking is cheap and fast either way.

The Foundry Lab process delivers castings quickly by using 3D printed ceramic molds as an interim step. More in the linked article and video.

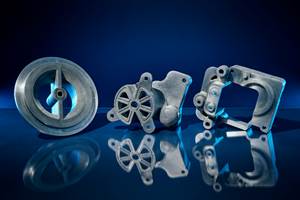

Something similar can be said of the system offered by Foundry Lab. This company’s AM process again is not aimed at realizing a 3D printed part, but in this case is aimed at realizing a casting. The system components include a 3D printer for producing a ceramic tool and a microwave furnace for melting metal into that tool, plus software assuring the 3D printed form produces the as-designed casting. Given the long lead times some buyers of castings have seen from metal foundries, the ability of the Foundry Lab process to go from design to finished casting within one day is transformative. Company leaders initially thought existing foundries would see them as a competitor, but foundries instead have been curious and receptive. Who better than these businesses to recognize the opportunity in castings delivered in faster time?

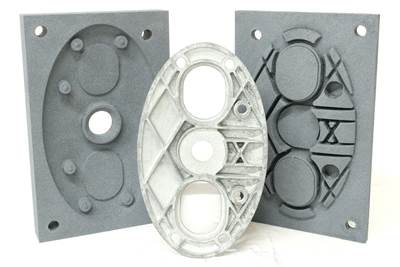

Indeed, a different application of AM for casting is already changing foundries’ roles. 3D printed sand tooling speeds and simplifies the exploration of cast part designs. Humtown Additive, a provider of this sand tooling, finds its customers now are increasingly OEMs rather than foundries. The OEM end users of the cast parts can now explore designs faster and cheaper using the quickly made 3D printed tooling, going to the foundries only when the cast part design is final and ready for full production.

This last example illustrates something key. That is, the most lasting impact of a process becoming cheaper, faster or simpler is that the options for when to apply the process can expand and change. If there is easier moldmaking, for example, then I do not have to wait until I am certain of a plastic part’s design before committing to making the mold. And if there is an easier way to obtain a casting, then I do not have to order castings long before I need them because of the expected wait. I still might do these things, because the new AM processes do not cover all molds or all foundry needs. But as the array of viable options expands, plenty of innovation and cost saving will be found within the new pathways.

All this brings me back to the critique at the start, the comparison between additive and existing processes. Inherent to comparisons such as this is the assumption that additive manufacturing and conventional manufacturing are in competition. Are they? In part, yes! AM has taken over for casting, molding and machining in various production applications. But then, is additive enabling conventional processes? Also yes! The articles linked above make as much clear. In the end, the alleged competition between new and established processes is hard to evaluate, because the advance of 3D printing is making both additive manufacturing and conventional manufacturing better.

Related Content

Is 3D Printing Competing with Casting? AM Radio #27B

On this episode of AM Radio, we discuss two examples of companies that are shortening supply chains by using 3D printing instead of casting.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreCasting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreRead Next

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read More