Companies using industrial 3D printing often begin with making tooling before realizing the opportunities for production parts — and now the very same pattern is happening with the largest additive manufacturing machines! Additive Engineering Solutions (AES) was founded to apply Big Area Additive Manufacturing (BAAM) capability to making large tools for applications like composites layup or concrete, but aerospace and defense engineering company L3Harris turned to AES to manufacture a production part, and a big one at that: the near-complete outer structure of a flight simulator cockpit. 3D printed from carbon-fiber-reinforced polymer rather than assembled from thousands of smaller components, the new simulator housing design simplifies manufacturing and shortens lead time, as L3Harris team members describe in this episode. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Additive Engineering Solutions

- L3Harris

- Cincinnati Inc., maker of the Big Area Additive Manufacturing (BAAM) system

- BAAM for tooling applications

- BAAM for concrete tooling

- Another AES production application, Autonomous Underwater Vehicle

Transcript

Stephanie Hendrixson

This is our biggest 3D printed part yet.

Peter Zelinski

Find out what this is and how it was made on this episode of The Cool Parts Show.

Peter Zelinski

The Cool Parts Show is brought to you by Carpenter Additive. When it comes to managing metal powder. There is no one size fits all approach. Stick around after the episode to learn more.

Peter Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Peter Zelinski

Welcome to The Cool Parts Show, our show all about cool, amazing, disruptive, transformative, manufactured parts made through 3D printing.

Stephanie Hendrixson

If the show is familiar to you, today's setting might be as well. we are at additive engineering solutions AES in Akron, Ohio, and we've been here one other time. We filmed an episode previously inside of the big area additive manufacturing machine. That's right behind us. But today we're here to talk about something different. Pete, what is that?

Peter Zelinski

Yeah, yeah, AES, Akron, Ohio, company specializes in really big 3D printed parts. The company was founded with the expectation they would be using these BAAM machines, big area additive manufacturing, to make tooling. But we're going to talk about something happening for these big machines that is happening with 3D printing technology at all scales, which is the move into production. We're going to talk about this, which is a repetitive scale production, big 3D printed part.

Stephanie Hendrixson

Alright, so let's start with the literal elephant in the room. What is this part?

Peter Zelinski

So this is a flight simulator. AES is producing this for L3Harris, an engineering company that is into a whole lot of systems for defense and aerospace, including flight simulators in various fashions. This is a flight simulator for a military aircraft. They're made for commercial aircraft as well. This is not a complete flight simulator, obviously, but it's a whole lot of it, it's the structure. And this structure will get customized, so that it looks just like, feels just like the cockpit of the aircraft it was intended to replicate.

Stephanie Hendrixson

Okay, so not a literal plane, but a simulator that has to be an accurate representation of that plane. So let's talk a little bit more about that, what are the actual requirements for a flight simulator and what is this going to be used for?

Peter Zelinski

So kind of straightforward. If your pilot is still in training, you don't want to send them up in the plane. But even more than that, if the pilot is sharpening their skills, don't burn fuel for that, don't put wear and tear on the plane, the flight simulator is a way to simulate the flight experience. So this is pretend flying, but it is real production. Because this cockpit, this simulated cockpit has to very closely match the actual cockpit of the actual plane. And that means that it is manufactured to something very close to the same requirements and tolerances. And one of the requirements here even is it's got to feel to the pilot, just like the real cockpit feels when the pilot jumps in.

Stephanie Hendrixson

Okay, so the simulator has to be the same size and shape is a real cockpit, it also has to feel the same when the pilot climbs in. I'm gathering that 3D printing is probably not the way that they typically make these. What's the original manufacturing process?

Peter Zelinski

Right, the original process was assembly, lots of assembly, lots of components. So a structure like this formerly involved lots of machined metal parts, laser cut parts, fiberglass parts. L3Harris saw an opportunity to significantly consolidate assembly, and a large part of that consolidation was replacing what used to be an assembly of a whole lot of components with a big monolithic 3D printed form. To talk about that, here is Mark Roberts; he is program manager of international programs for L3Harris.

Mark Roberts

We were looking for ways to reduce our manufacturing costs and to improve the maintainability of the device and the lifecycle cost durability. But primarily it was upfront manufacturing costs, looking how to reduce how to reduce that. So we undertook an initiative to investigate using additive manufacturing. The metrics were somewhere around 3,000 parts down to somewhere around 300 parts.

Stephanie Hendrixson

Okay, so extreme assembly consolidation. They started with 3,000 some parts, they took it down to about 300 including the couple of 3D printed parts that we have here. But usually when we talk about assembly consolidation, there's some element of DFAM, design for additive manufacturing that has to happen. Was that the case here?

Peter Zelinski

Yeah. Yeah, design for additive manufacturing, we talk about that a lot. The way that you can't just take the component the way it used to be and print it. And so there was a lot of conversation between AES and L3Harris going back and forth about how exactly should this structure be re-engineered reinterpreted for 3d printing. So here are a couple voices here is Mark Roberts, again, along with Paul Mueller, who is the director of hardware engineering for L3Harris.

Mark Roberts

We have a lot of experience internally, designing the components, but we've never designed anything that can be built using additive manufacturing process. So we designed our SolidWorks 3D model, and we worked directly with the engineering team at AES, went back and forth, back and forth. We would send them the model, and they helped us enhance it, and adjust our model, so that it could be readily built using additive manufacturing large format printing process.

Paul Mueller

I'll say that our first experiment into an additive manufactured cockpit, we tried to replicate how we would do the design out of metal or out of fiberglass, and really found that that wasn't achieving the savings in the part count reduction we wanted. So we really started and revisioned or re-envisioned what this cockpit was gonna look like using this technology. Started with a clean sheet of paper, started with a clean model, if you will, and built that up using only the design parameters of, how does the pilot interface with it, what does the pilot see from within the cockpit? Those were the primary governing criteria.

Stephanie Hendrixson

Okay, so L3Harris is looking for a more affordable way to build these flight simulators. That leads them to large format 3D printing and AES. And then together they have to kind of redesign, actually reimagine, the design of this structure for 3D printing. But Pete, I'm looking at this thing behind us and I see a lot of surfaces that look 3D printed, but I also see a lot of surfaces that don't. I think maybe we need to talk about machining.

Peter Zelinski

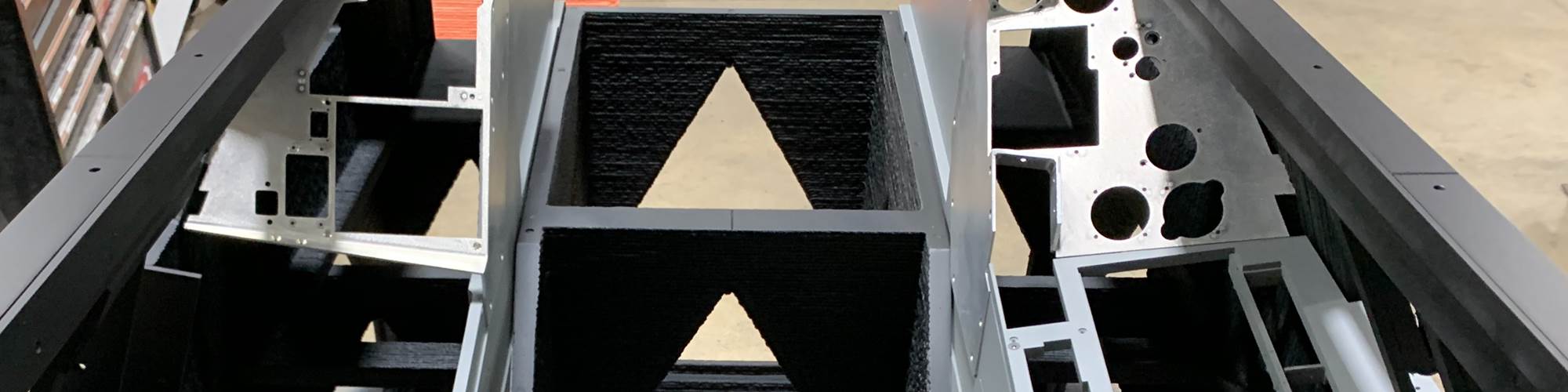

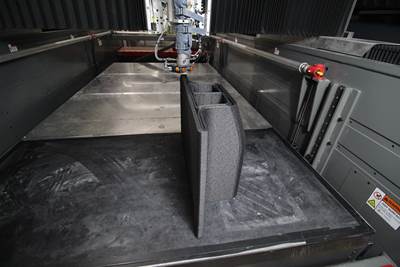

So really there are there are three big 3D printed parts in the structure behind us. There's sort of a big foundational piece and then mirror image components that sit on top of it. And to your point, these surfaces don't look like what would come off of a 3d printer. There was machining involved, there was a significant amount of machining involved. This is 3D printing for production and what we know about additive when it's applied for scale production is the post processing considerations become vital and machining was a significant part of the post processing here. If we look sort of on the inside of these pieces, some surfaces that are going to be covered over with panels later, you can still see the texture of the 3D printed form. The material here is a polymer composite, it is fiber reinforced, it lends itself to machining and machining got this appearance structure on the outside. We talked about design for additive manufacturing before, but this part, these parts they also required design for machining. Let's talk to a AES's founders here are Andrew Bader and Austin Schmidt.

Andrew Bader

The machining challenges we faced on the cockpit was really the overall complexity of the part. Most of the times with a tool or mold, you have a single surface that you're contouring. But with these parts, we're really surfacing and machining all sides, inside, outside. There's just a lot more machining than we typically do on our 3D printed parts. So on average, we're printing about one hour to every three hours of machining time. On this project, it's more of a one to five ratio of printing to machining. So a lot more machining involved. But we had to do a lot of optimizing on the printing portion of it. So when we got to the machine department, it was as efficient as we could be to remove material, pocket things and machine it complete.

Austin Schmidt

I think we've probably spent as much time designing for machining, as we did designing for the printing process. When it comes to designing for machining for large format additive manufactured parts there's several things to take into consideration. One is the scaling that you're going to use to account for the shrinkage and the warpage in the process. Just the same as how you would have shrinkage or warpage on a small FDM machine, where you might get a part curling up off the build table, you can get the same thing happening on a large format 3D printed part. Except in our case, it might warp an inch or two off the table. So you need to be able to account for that and design to reduce that warp that may occur. You also need to be able to scale the part to account for just the natural shrinkage of a polymer part. On top of that, you also need to think about how the part is going to be fixtured. Basically, when the parts come off the printer, they're essentially similar to a casting in a sense, there's no real true flat, straight or square surface. So trying to build in a surface that helps allow you to indicate the part in during the machining process, or kind of gives you your datums for machining, it's important to include that in the 3D printing design.

Stephanie Hendrixson

So that's interesting, Austin just talked a little bit about how some of the issues you might see with a smaller FDM printer are still issues when you move to these really big FDM style printers. And I know we talked earlier about how AES sort of started with this idea that they would be making tooling, and this is a different type of job for them. Similar to what we've seen with smaller FDM printers, right from moving from tooling into production. And I'm wondering, you know, how did their thinking have to change? What challenges did they face in taking on a job like this?

Peter Zelinski

Yeah, so they had to develop a quality management system. Tooling, the work they're used to is usually a one off part that doesn't repeat. But in this case, they had to figure out with their customer L3Harris, what are the measurement requirements here? What are the quality requirements. They had to work that out and develop a system for attaining that part after part. This isn't just a few 3d printed parts. As we look closer at this, there are some machined metal parts, there are some brackets that go on here. AES had to source those. AES turned to other companies to get those parts made. This is a sub assembly, and so AES had to develop a supply chain.

Andrew Bader

The added layer of complexity with doing serial production, especially on this project for us, is we have many subcontractors. We are used to subcontracting parts out here and there, but on this project we've got four or five of them, right, we have a handful. So we have to track all that. We have to make sure that our subcontractors are staying on time. So we have to, you know, vendor performance. There's just a lot more project management overall, to dealing with a project like this and serial production. Now it also gives us the opportunity to hone in and optimize our manufacturing process, our assembly process, right. Typically, we're not used to certain storage, and shelving, and labeling parts, because we don't really have things in stock ever. But now for this project that we have to make several cockpits, we made several different quantities upfront, we put those into stock, we have to account for those, label them. So everything is very organized. Beforehand on a one off project, which is mostly what we do, we never had to worry about that.

Stephanie Hendrixson

Okay, so this is a real business shift for AES. They're going from that tooling mindset to production, they have to figure out inventory and supply chain and all these other things that they haven't had to deal with before. And from L3Harris's perspective, this is a different process for them too. They're used to kind of getting all of those 3000 parts, they have to assemble and put together themselves, and now they're getting something that's much more complete when it shows up in their facility. And I wonder what are the benefits that they see from that that process change?

Peter Zelinski

Right, so you kind of identified one of them there, it's simplicity. This is from their perspective, a much simpler process. When they were doing the assembly, there's not only there's not only all that work of assembly, but there is all of that part management, all of that control and inventory. They're free of that. But another big benefit we haven't really touched on yet is the time savings.

Paul Mueller

So we're about 50% reduction in time for production and probably 70% reduction in time for the first article. When we started this project we went through and planned on a first article prototype to validate the process and validate the design. We finished that in six months which was probably three months ahead of schedule, and now we've built the first production forward cockpit component. The first production aft cockpit didn't have a prototype, we went right from the design, from the engineers design to that production article in one step.

Stephanie Hendrixson

Okay, so I think I got this, what we have behind us is a flight simulator for L3Harris being made here at Additive Engineering Solutions. L3Harris was looking for a more affordable way of building these flight simulator bodies, which led them to large format 3D printing, AES and L3Harris had to do a lot of redesign and reimagining to convert the design for 3D printing, and also for machining because that was a significant part of this process as well. And this is a case of extreme assembly consolidation, L3Harris is going from 1000s of parts into each one of these simulators down to hundreds. And this is also a shift for additive engineering solutions, because now instead of making one off tooling, they're doing something in serial production, they're managing inventory, they're managing a supply chain of subcontractors. And the result of this project and them working together is that L3Harris is able to build these more affordably. They're also saving a whole lot of time in doing it this way.

Peter Zelinski

All right. Thank you for watching. Thank you Additive Engineering solutions for hosting us one more time. If you have a cool part you'd like to tell us about, big, small or otherwise, email us CoolParts@AdditiveManufacturing.media.

Stephanie Hendrixson

If you liked the show, we hope you'll subscribe, leave us a like, leave us a comment. If you're on YouTube, click the bell icon to get notified about any new episodes. And thanks for watching.

Peter Zelinski

This episode is brought to you by Carpenter Additive, we're past the point of not knowing how to qualify metal 3D printed parts. We know, it's just that different end users of those parts have different qualification requirements. Additive manufacturing service providers have to navigate that, and Carpenter Additive has to think about that in tailoring powder management solutions.

William Herbert

Our customers typically will have, if they are a service provider, they will have a series of end user customers who may be say OEMs in the aerospace world. And each of them has a fairly large team of engineers who've been doing this for decades or more, and have developed all these standards, regulations, paperwork. So it is certainly a challenge to thread the needle between all of these different requirements. We start really high level, we walk on the shop floor, we ask them about their source to sink, how do you bring in materials, goods in, send that material to each of the systems. And then what we're really interested in is how do they reuse that material. So what we do is called a Value Stream Map. Pretty often that leads to a series of things that were either overlooked or hadn't really boiled up to the surface yet in terms of things that are potential risks, or potential challenges or inefficiencies that exist. A lot of the customers we work with, especially in the more regulated industries, such as space, or medical or aerospace, have already been through those early learning stages. They've put five plus years into this. They've done the product design and the design for additive manufacturing. And now they're starting to reach some of the more finicky problems that you get when you're at the scale of maybe 5 or 10 machines. You're running different materials simultaneously. You're doing different programs. We get to take the best from the medical field and the aerospace field. We understand the specifications and the standards that exists in each of those fields, and we can sort of take the best elements of those and customize that to our customers.

Related Content

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreNew Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreHow to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreRead Next

Autonomous Underwater Vehicle With 3D Printed Hull: The Cool Parts Show #24

Our first episode of The Cool Parts Show from inside a 3D printer! Big Area Additive Manufacturing (BAAM) produces exterior components of a robot submarine and changes how this AUV is marketed.

Read MoreOhio Business Sees Big Possibilities in BAAM for Tooling

A new startup built around a large-scale 3D printer aims to offer short lead times for large industrial tools.

Read More3D-Printed Tooling Offers Durability for Precast Concrete

As an alternative to wooden tooling, 3D-printed forms for precast concrete are proving to be more durable and better able to support a large-scale renovation project.

Read More