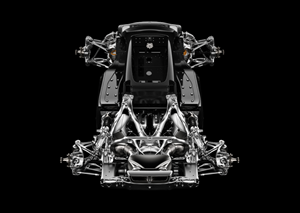

With its high strength to weight ratio and recyclability, aluminum is a popular material choice for automotive parts, like this demo part, which is modeled after an automotive inverter housing. But traditional methods for producing high-volume aluminum parts, such as casting, require permanent tooling, which can create supply chain problems. Photo Credit: Alloy Enterprises

As demand for electric vehicles increases, the demand for strong, lightweight materials such as aluminum will increase as well. At the same time, manufacturers want the advantages of 3D printing, including complex geometries, conformal cooling channels and freedom from tooling. But aluminum, especially alloys such as 6061, can be difficult to print using powder bed processes. According to Ali Forsyth, the co-founder and CEO of aluminum 3D printing startup Alloy Enterprises, this is because these processes weren’t created with aluminum in mind. “Seeing that permanent mold and investment casting were still the primary methods to get these volumes of components, it occurred to us that aluminum really deserves its own unique process,” she says. The company developed its selective diffusion bonding process especially for aluminum, with scale production in mind.

“Seeing that permanent mold and investment casting were still the primary methods to get these volumes of components, it occurred to us that aluminum really deserves its own unique process.”

3D Printing Aluminum

Forsyth founded Alloy Enterprises in early 2020. After obtaining a PhD in engineering from Harvard, she worked at six hardware startups, including Desktop Metal, where she met Alloy’s CTO, Nick Mykulowycz, who has developed five metal additive processes. The company’s third co-founder, COO Andie Bedell, brings sales and operations experience from both Fortune 500 and startup companies.

Forsyth says that she gained an appreciation for aluminum during her time at Open Water Power, a startup that developed an aluminum seawater battery for unmanned underwater vehicles (UUVs). “It’s infinitely recyclable, which, as a starting point is just incredible,” she notes. Combined with a strength to weight ratio that’s twice that of steel, it’s easy to see why aluminum is so useful in automotive applications, especially as car makers are looking to reduce weight in electric vehicles. At the same time, additive manufacturing technology in general is starting to break through. “3D printing is really on the precipice of getting to throughput in manufacturing,” Forsyth says. “We have the opportunity to leverage the incredible technological advancement that's happened so far. But we still needed to make a step change into cost reduction to break into higher volume markets.” Specifically, the team wanted to move away from using aluminum powder to help scale production, reduce costs, and increase safety and ease of use. This will help enable additive manufacturing to gain wider adoption in the automotive and industrial equipment market verticals and replace traditional processes like casting. “We saw this void in part volumes where no manufacturing process, additive or conventional, is serving the needs of the market,” she notes.

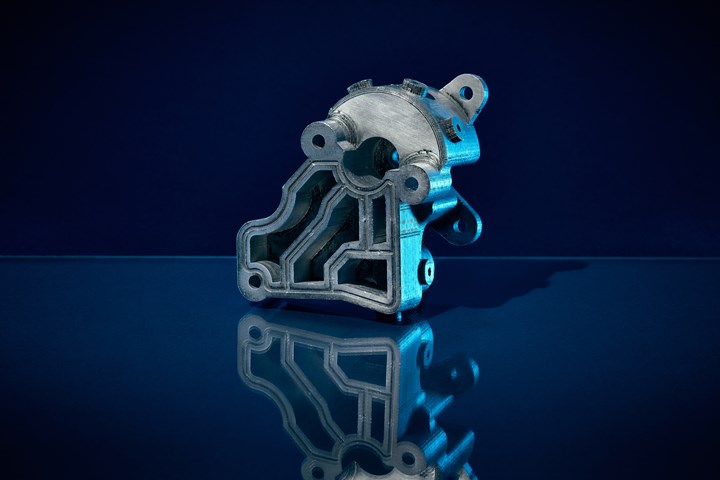

Alloy Enterprises’ selective diffusion bonding process is an additive manufacturing process designed specifically for aluminum, using a proprietary aluminum in sheet form as the feedstock, instead of powder. The resulting parts, including this demo part that’s modeled after an oil filter housing, are homogeneous 6061 aluminum, with strength and elongation at break that are said to be a step up from casting materials. Photo Credit: Alloy Enterprises

Selective Diffusion Bonding

Selective diffusion bonding is a sheet-based process that uses a novel aluminum feedstock developed by the company. “The material is required in order to make the bonding process work,” Forsyth explains. But the key is that the company didn’t invent a new manufacturing method to produce the material. “We're relying on the aluminum rolling process,” she says, “which makes the aluminum foil in your kitchen and soda cans.”

So far, the company has produced 14 tons of material, and it says that the cost is 1/25 that of aluminum powder. “Not having to rethink how to get to high throughput and low cost of the feedstock was really key,” she notes. It will also be essential as the company scales production. “To really be competitive in higher volumes, it’s difficult when powder is your starting point.”

There are benefits to not using powder beyond cost. It eliminates steps such as baking, sieving and de-powdering. And rolled aluminum doesn’t have the hazards inherent with metal powder. The process doesn’t require protective equipment such as respirators or special storage, and there’s no risk of the material exploding.

Selective diffusion bonding involves two machines. The first one, called Construct, dispenses sheets of material and cuts the outline of the parts with a laser. “There's a speed advantage because we don't need to go voxel by voxel through the whole area,” Forsyth notes. “We just outline the perimeter.” The machine then applies an inhibiting agent to certain areas of the material, which prevents layers of material from bonding to create supports, overhangs and other complex geometries.

The Construct machine has in-process inspection that scans each layer. “Everyone in additive manufacturing has had that moment where they come in in the morning and the build has just failed,” Forsyth says. “Or worse, there’s a defect inside your part and you can only detect it with nondestructive testing.” Inspection has reduced the failure rate of the company’s builds, enabling it to make rapid progress as it develops and refines its processes.

In selective diffusion bonding, a machine laser cuts the sheets of material and applies an inhibiting agent that creates supports. After the sheets are stacked and bonded, the supports are broken away to expose the parts, such as this part for an industrial equipment manufacturer. Photo Credit: Alloy Enterprises

The machine stacks the sheets up automatically. When complete, an operator moves the caddy to the Bond machine. In this machine, parts undergo a diffusion bonding process to fuse the sheets of material together, except in the areas where the inhibiting agent is applied. During diffusion bonding, the stacks of sheets become a block of material with parts nested both horizontally and vertically inside. The support material can then break away to expose the parts.

The resulting parts are homogeneous 6061 aluminum, with strength and elongation at break that Forsyth says are a step up from casting materials. The broken away supports are made of the same 6061 material. “It’s a known composition and large and clean enough that it has scrap value,” Forsyth notes. “So it will go back to the mill and be reused.”

The parts then go through standard heat treatment. Tight-tolerance features can also be machined if needed, similar to traditional castings, although Forsyth expects the need for post-processing to be minimal. She says that the company has gotten good feedback from customers on the surface finish of the as-printed parts.

Forsyth says that there are fewer considerations required when designing for selective diffusion bonding compared to other manufacturing methods. As long as the part is castable and within the machine’s build volume, Alloy Enterprises can produce it, while including complex geometries and conformal cooling channels that casting can’t.

This customer part, for an industrial equipment manufacturer, shows the as-build surface finish that selective diffusion bonding can achieve. Customers can choose to machine critical features, although the company expects this need to be minimal based on customer feedback. Photo Credit: Alloy Enterprises

Getting To the Next Stage

Right now, Alloy Enterprises is running fully functional pilot systems in its labs. It is producing parts for customers, who are evaluating them, qualifying them, and providing feedback to the company. “We’ve really been engaging with our customers early on to make sure that we're making real parts for real applications,” Forsyth explains. The company is also working on its next iteration of machines, which it plans to scale. “The systems that we’re designing right now, one machine will be able to produce over seven tons of parts in a year,” Forsyth says. It also has scaled up production of its proprietary material. “We’ve already established the supply chain for that, and that can be done safely and economically,” she adds. From there, the company plans to act as a parts supplier, making parts at its facility, which it refers to as a Digital Aluminum Fab.

For its materials strategy, the company is concentrating on 6061. “We’re staying focused on that one for now,” Forsyth says. But she also doesn’t rule out adding more materials in the future, along with other possible ways to expand the technology. “There’s a lot of potential, and we are only at the beginning of uncovering what is possible with this technology.”

Related Content

A Tour of The Stratasys Direct Manufacturing Facility

The company's Belton manufacturing site in Texas is growing to support its various 3D printing applications for mass production in industries such as automotive and aerospace.

Read MoreDivergent Technologies Eyes High-Volume, Optimized Automotive Production Through Additive

While some automotive OEMs are using additive here and there, Divergent Technologies is basing its vehicles on 3D printed structures.

Read MoreHow AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read More3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read MoreRead Next

How GM Is Investing in Additive and EVs

People within the automaker aren’t just working with additive, they are actively promoting it to their colleagues throughout the organization.

Read MoreMultimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.

Read MoreNew Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

Read More