Evolve's STEP process uses technology that borrows from high-speed imaging to rapidly apply layers of material. It can print parts in batches at a deposition rate up to 286 cubic inches per hour. The horizontal image at the top of the page shows a component made using STEP that would otherwise be injection molded. Photo: Evolve.

Evolve Additive Solutions is preparing for a time in which additive manufacturing directly competes on cost for scale production applications against conventional manufacturing methods, particularly injection molding. Indeed, company co-founder, CEO and president Steve Chillscyzn says leading with part cost — not the design freedoms, which come later — is proving to be the best way to find opportunities for its AM system.

This is new. The advance of additive manufacturing so far has been the result of AM justifying itself by filling needs other production processes cannot. There are many of these, related to part consolidation, lightweighting, intricate forms, customization and production at small lot sizes. In most cases, AM justifies a higher unit cost per part because of the advantage it brings. But Evolve offers an additive process — the Selective Thermoplastic Electrophotographic Process, or STEP — that is capable of 3D printing polymer parts at speeds and price points in the neighborhood of molding.

Steve Chillscyzn is company CEO. Finding opportunities for Evolve's AM process often involves matching the possibilities of other processes, he says — meaning comparable speed or cost and the same material. Photo: Evolve

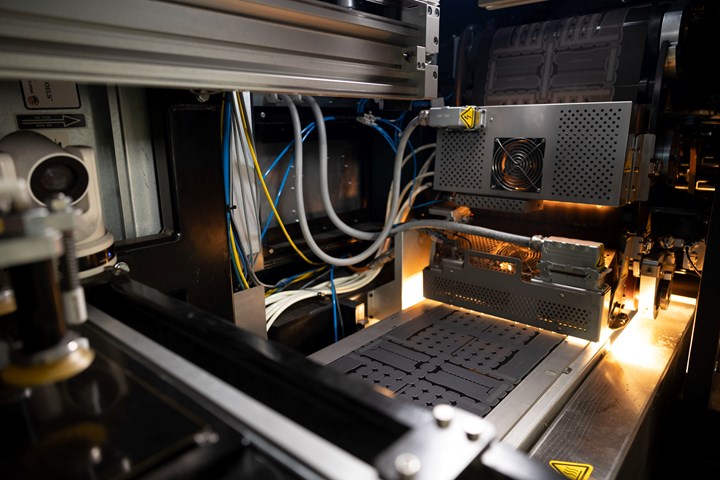

I spoke with Chillscyzn during a recent visit to the company’s Minneapolis-area headquarters to get an update on the company’s machine and process, which have spent years in development. STEP involves deposition of polymer via imaging. It is high-speed 3D printing that borrows from high-speed 2D printing. Rather than printing documents, the process uses electrographic imaging to print material layers. High-speed closed-loop control of X, Y and Z assures precise resolution and consistency through rapid builds of part and support material, and for rapidly applying combinations of materials in a single part. The company’s Model SVP production AM system is capable of a build rate of 286 cubic inches per hour, meaning one machine can deliver about 8 metric tons of 3D printed plastic parts per year, the CEO says.

A notable feature of my visit was an enclosed, finished, operating commercial version of the SVP machine, which is about the size of a small school bus, and which was running alongside the company’s original process development platform. One customer has a production machine like this in use; two others will be receiving theirs soon. The machine represents a different modality and range of possibility for 3D printing in polymer part production, and early customers are helping to explore and characterize it.

The company is beginning to place initial machines with chosen customers able to run (and evaluate) the machines in various production applications. Photo: Evolve

Chillscyzn says part cost will be the fastest way forward for winning the STEP process’s acceptance. The advantages of 3D printing over injection molding are compelling, including the design advantages and freedom from tooling, but a higher cost per part forces users to weigh the value of these advantages against embracing a new process. AM competing on cost overcomes this obstacle. One user to receive one of the next machines to be built will be digital manufacturing service provider Fathom. Evolve and Fathom will be developing a STEP costing tool to more readily identify opportunities for this process.

A basic production part, but with a spin only 3D printing can provide: This set of brackets is printed as a set, with the connector tie included. The set can therefore be made and inventoried as a single object, rather than tracking each bracket separately. Photo: Evolve

One other important lesson the company has had reinforced is, in Chillscyzn’s words, “Materials, materials, materials.” At high volumes, he says, “Established manufacturers do not want ‘like’ materials; they want materials they’ve specified and are accustomed to using.” Evolve’s development work has focused on this. A result: “Our ABS today is the same material from Sabic any injection molder would use.”

Part examples I was able to see revealed various application possibilities. Lego and Stanley Black & Decker are among the investors in Evolve — so I saw new variations on interlocking bricks and hand tools. Also, for example, a fluid manifold 3D printed in one piece with built-in watertight ball valves included, and a set of nine related brackets for a major manufacturer with a printed-in tie piece holding them together for inventory control. These are new ideas. And these are the kinds of possibilities AM will realize. But in many cases, says Chillscyzn, getting to achieve something new is what AM has to do second. First, AM has to win acceptance as a production process on its own merits, before the part can be changed to take advantage of AM.

Related Content

To Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read More8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

Read More3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreRead Next

What A Former Moldmaker Has Learned About AM: Leverage Simplicity and Let It Scale

The once-again independent Linear AMS is now more focused on additive manufacturing than ever before.

Read MoreReshoring Manufacturing With 3D Printing: The Cool Parts Show #34

Wet-dry vacuum maker shifts to additive manufacturing for first entirely U.S.-made product, a jackhammer accessory. More U.S. production to come via 3D printing.

Read More5 Scenarios Where Additive Manufacturing Should "Win" the Production Work: AM Radio #14B

In some cases, it makes sense to switch from 3D printing to some other process, but there are also cases where AM can and should win the production work. Here are 5 examples.

Read More