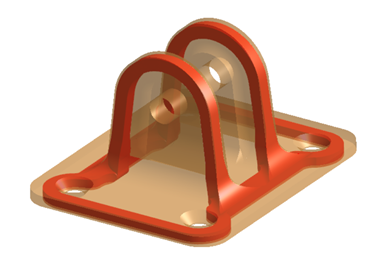

Compression molded polymer composites can go even further with the addition of 3D printed reinforcing structures. The 3D printed continuous carbon fiber piece in the foreground reinforces the base of the aerospace bracket seen behind it, adding strength only where it is needed.

“Think about all the brackets inside a commercial aircraft today, and how many are metallic,” says Konstantine Fetfatsidis. “Changing from metal to carbon fiber, you’ll lose weight but probably not cost. Traditionally with composites, that’s been the Achilles’ heel that prohibits small parts from being made this way.”

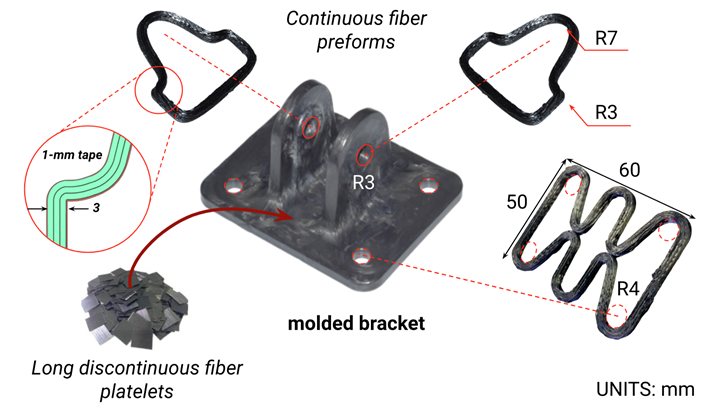

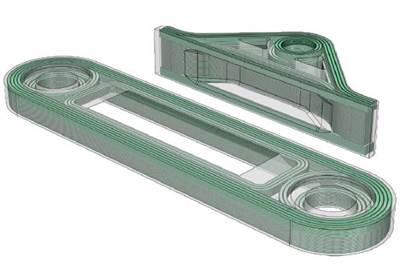

The two “ears” of the pin bracket shown above are reinforced with identical preforms that look like this.

Photo Credit: 9T Labs

Fetfatsidis is the North American president of 9T Labs, a technology provider aiming to reduce the barriers preventing those small metallic parts (think brackets, hinges, latches) from being made through composites instead. The advantages of making the switch are multifaceted. 9T Labs’ Additive Fusion Technology (AFT) provides a method for producing fiber-reinforced thermoplastic composites that frequently results in a unit cost per part that is lower than machined metal for production runs up to about 100,000 parts. The technique is less wasteful than traditional machining, while capable of providing the same or better mechanical performance as metal in a lighter-weight component. The change in material and process consolidation brings benefits on the manufacturing side, while the reduced weight of these parts potentially delivers huge savings in fuel and energy usage for applications such as aerospace and electric vehicles.

Meanwhile, the continuous fiber reinforcement that is possible through AFT supports stronger composite parts than can be achieved through molding alone. The 3D printing step enables automation along with greater geometric freedom than hand-laid composites, while the resulting preforms lend targeted strength to compression molded polymer composites. In effect, this makes the so-called “hybrid” composites a better potential replacement for metal parts than has previously been possible to manufacture.

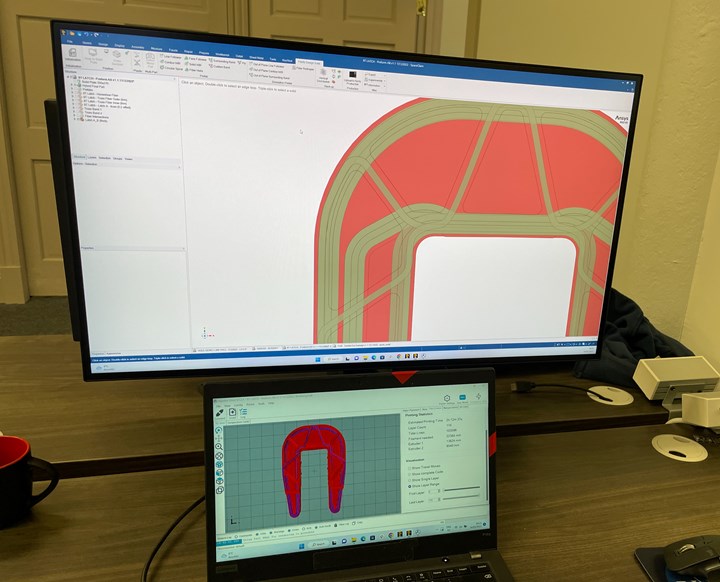

The fibrify Design Suite (fDS) software allows for placement of continuous fiber reinforcement as well as optimization and validation of the design. FEA simulation integration is supported as well.

How Does Additive Fusion Technology Work?

Despite having the word “additive” in the name, AFT is really a method for achieving a compression- or flow-molded composite part. The technology provided by the company includes three key parts: the Build Module which performs the 3D printing, the Fusion Module which performs the compression molding step, and fibrify Design Suite (fDS) software to design and simulate fiber layups before sending to production.

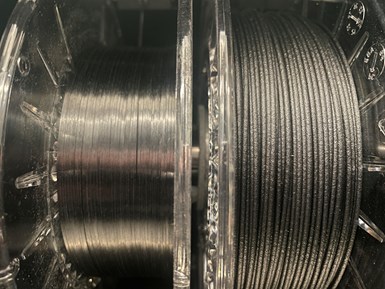

9T Labs’ Build Module can lay both thermoplastic unidirectional tapes (left; the material shown is carbon fiber prepreg cut from a wider spool) and more conventional 3D printing filaments (right; in this case, a polymer reinforced with chopped carbon fiber).

The Build Module can apply both polymer filament (reinforced with chopped fibers or not) and 1- to 2-mm-wide thermoplastic unidirectional (UD) tapes to create the preform for the part. Sometimes that means printing a nearly complete part with areas of continuous fibers and areas of neat polymer, but sometimes it means building out only the geometry for the reinforcing fibers. The preform and any additional needed material is then compression molded to eliminate voids and achieve its final form in the Fusion Module.

The end-use parts are equivalent to other compression-molded pieces and can be certified as such for applications in aerospace, ground mobility, medical and more. Additionally, the thermoplastic composites have multiple recycling and upcycling pathways once they reach their end of life for a given application.

We first covered 9T Labs back in 2021, just as its Red Series AFT package was entering the marketplace. Now in 2023, 9T Labs has grown as a company, expanding into North America with a new office in Lowell, Massachusetts, that doubles as a production center for customer work. (The company offers AFT services as a strategic supplier, as well as providing the hardware and software to OEMs that own and operate the equipment themselves.) 9T Labs’ application of AFT as a lightweight alternative for metal parts has evolved in that time as well. Now, rather than printing reinforcing fibers to be used only in one plane, 9T Labs is using the compression molding step frequently to bend those preforms to provide optimal support and strength.

Jordan Kalman (left) and Konstantine Fetfatsidis (right) show me the Red Series equipment in use at the company’s North American headquarters in Massachusetts. The full solution has a compact footprint; one Fusion Module can serve up to three Build Modules, depending on the size of the parts and needs of the application.

Control the Failure with the Preform

For example, this pin bracket for the overhead bin of an aircraft developed in collaboration with Purdue University has three preform pieces: a “base loop” piece that reinforces the four holes at each corner and also bends upward into the two “ears,” and two identical preforms that reinforce the holes found on those ears.

This pin bracket is designed for use in the overhead bin of an airplane. This illustration shows where the 3D printed continuous fiber preforms fit inside the finished component, the rest of which is composed of long discontinuous fiber platelets. Image Credit: 9T Labs

The preforms are printed from continuous fiber thermoplastic UD tape and placed into the tool prior to compression molding in the Fusion Module. The remaining material needed to construct the bracket is a thermoplastic bulk molding compound (BMC) that includes chopped carbon fiber platelets. According to 9T Labs, the continuous fiber improves the load transfer between the ears and the base, delivering increased strength and decreased variability compared to BMC-only parts.

The CF-PEKK preform seen at the right reinforces the base plate of the pin bracket. Weighing just about 3 grams, this component adds strength around the bolt holes without introducing extra weight.

(Other types of moldable materials can be used as well, and the company is experimenting with chopping up unneeded prints to use for this feedstock.)

Choosing a composite bracket versus machined steel saves weight and reduces waste in production, but using this type of highly controlled reinforcement has another major benefit: “We can choose where we want it to fail,” says Jordan Kalman, application engineer. Without the continuous fiber reinforcement, the bracket would be prone to breaking by its ears; with the printed preforms incorporated, it is more likely to crack at the base. The addition of the continuous fibers also greatly increased the load at the onset of failure, illustrating the possibilities for tailored part performance.

A simulation of an earlier bracket iteration showing how the continuous fiber preforms provide reinforcement for the holes in the base and around the ears. Image Credit: 9T Labs and Purdue University

The implication for composite parts incorporating these precisely controlled preforms is that they can be designed to perform like metal only in the places where that performance is necessary. Rather than milling the entire bracket from aluminum or steel just to have the properties of that metal in the areas of stress concentration, AFT makes it possible to avoid waste in the manufacturing of the bracket and create a lighter structure that offers the necessary mechanical properties localized around critical features.

In the case of this pin bracket, the addition of the continuous fibers also greatly increased the load at the onset of failure, illustrating the possibilities for tailored part performance. And, the combined technique allows for parts that are stronger than BMC parts alone and suitable for more demanding applications.

The Promise of the Tailored Preform

Additive Fusion Technology allows 9T Labs and its customers to better control the strength and performance of composite parts by providing greater control over the preform. But the final part is not understood as a 3D printed component — rather, it is seen as equivalent to a traditionally compression molded part. Composite parts made this way are not qualified as additively manufactured ones would be, but as compression molded parts made from commercially available materials.

“The 3D printer is almost a preforming machine,” Fetfatsidis says. “We use a known, proven process [compression molding] and known, proven materials. All we are adding is the ability to tailor the preform.”

A Build Module 3D printing the base loop for the aircraft bracket. In Additive Fusion Technology, the printing step becomes less a direct manufacturing method and more an automated means of producing composite preforms.

That tailored preform, in addition to delivering targeted part properties, could potentially reduce a lot of work in production. The molded finish of the parts tends to be high quality and ready for use right off the Fusion Module; the addition of colored filament for the exterior layers could even add color without the need for powder coating or painting.

9T Labs is currently focused on developing solutions for customers in specific markets, particularly aerospace and ground transportation (including motorcycles, bikes and more) where electrification is creating impetus to use lighter-weight components. The sweet spot right now is production of 1,000 to 100,000 parts per year; applications within those quantities include rocker arms for specialty motorcycles, parts for electric vertical take-off and landing (EVTOL) vehicles, watch cases and structural members in aircraft interiors (like those aircraft pin brackets), particularly in economy-plus style seating where quantities fit comfortably within the process’s optimal range.

“This is a next-level multimaterial, hybrid manufacturing method,” Fetfatsidis says. “We’re showing manufacturers how we can get them closer to the shape of the final part, not just the shape of the blank.”

The consolidated workflow and material property control possible with AFT also bring big-picture benefits as well. “A paradigm shift in how we view and use materials, especially at part end-of-life, is taking shape across industries,” Kalman adds. “We are creating a new manufacturing standard for strong, lightweight and sustainable parts cost-competitively.”

Applications for Additive Fusion Technology

Related Content

Faster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreWhy “Boring” Is Superlative for Additive Manufacturing: AM Radio #29A

It is impressive to be the biggest, smallest, first, only, thinnest and more additively manufactured part. But there is value in the average or mundane parts, too. We discuss examples on this episode of AM Radio.

Read More8 Social Media Posts About Additive Manufacturing: AM Radio #34

Cost savings, modifications, large-format AM and more. In this episode of AM Radio, we discuss what people are saying about additive manufacturing on social media.

Read MoreRead Next

Fiber-Reinforced 3D Printing Expands Control, Applications for Composites

9T Labs’ deposition process places continuous carbon fiber only where necessary to save material, reduce waste, and more precisely control the structure of preform composites.

Read More3D Printed Composite Bracket Versus Machined Steel: The Cool Parts Show #41

Can a 3D printed composite bracket work as well as one machined from steel? Can it also be faster to make and cheaper to produce? In this episode of The Cool Parts Show we explore a new way of manufacturing a bracket for a helicopter door hinge, and similar small parts today made from metal.

Read More3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

Read More

.jpg;width=70;height=70;mode=crop)