8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

The latest installment of Formnext, the world’s leading annual expo for additive manufacturing, was notable for the advance of new industrial 3D printing technologies as well as the expanded prominence of established options such as large-format robot 3D printing — and developments such as these figured into 3D printed part examples found at the show. Cohost Stephanie Hendrixson and I traveled to Frankfurt, Germany, to cover Formnext, and here is part of what we saw: eight of the coolest parts from Formnext 2023. | This episode of The Cool Parts Show is sponsored by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Formnext

- Reinforce 3D and the original RUAG 3D printed satellite bracket

- Cold metal fusion via Nexa3D and toolmaker Utilis

- Airtech Dahltram C-250 CF material, Hans Weber robot 3D printing and AIBuild

- Large format AM via robot by Caracol

- Horizon Micro Technologies copper coating of tiny AM parts

- Bright Laser Technologies and Titan Super Bond

- Silicone 3D printing by Lynxter

- Conflux Technology use of AM for heat exchangers

- More video in our Formnext 2023 video playlist

- Stephanie and Pete’s extended conversation about Formnext 2023 on AM Radio

Transcript

00:00:09:09 - 00:00:10:01

Peter Zelinski

I'm Pete.

00:00:10:01 - 00:00:10:22

Stephanie Hendrixson

I'm Stephanie.

00:00:10:22 - 00:00:21:09

Peter Zelinski

Welcome to The Cool Parts Show. This is our show all about 3D printing for manufacturing. And today we are looking at parts we saw at Formnext 2023.

00:00:21:09 - 00:00:35:07

Stephanie Hendrixson

Formnext is an annual trade show that takes place in Frankfurt, Germany. It is the world's largest show devoted to additive manufacturing. And today, we want to highlight some of the interesting applications, some of the places where additive manufacturing is really succeeding that we saw on the floor.

00:00:36:16 - 00:00:47:07

Peter Zelinski

is a huge show. This is just a taste. But here are eight of the coolest 3D printed parts we saw at the show. In no particular order. Stephanie, where do you think we should start?

00:00:48:21 - 00:00:53:21

Stephanie Hendrixson

All right. So I want to start with this multi-material reinforced satellite bracket. This is something that I saw in the Reinforce3D booth. Reinforce3D is a startup that has this technology for enhancing 3D printed parts or parts made with other processes. So basically how it works, you design 3D, print your part as you would normally, but include some channels for this reinforcement. After the part is complete, you would connect it to their system, which is able to feed carbon fiber and resin into those channels and provide additional reinforcement.

00:01:20:18 - 00:01:26:02

Stephanie Hendrixson

So reasons to do this, you can make a polymer part stronger. You can make a metal part lighter, you can even join those two things together. And that's what this is.

00:01:29:09 - 00:01:37:09

Stephanie Hendrixson

So this specific satellite bracket might look familiar. It is based on one that was optimized by RUAG for metal 3D printing, but reinforced 3D optimized it further. And one of the things that they did was they printed it in two different materials. So the lower part that would attach to the satellite is 3D printed aluminum made through laser powder bed fusion.

00:01:49:02 - 00:02:16:01

Stephanie Hendrixson

The upper portion, which can just be really lightweight, is PA12, made through multijet fusion. And then this reinforcing technique is what is uniting those two parts together. So by doing that, they reduce the weight of this component by 48% and they also reduce the cost by 60%. A lot of that comes from reducing the size of the metal part so that it can be made in most laser power bed fusion machines and you can actually nest a few of them together.

00:02:16:03 - 00:02:23:08

Stephanie Hendrixson

So I thought this was a really interesting part for the way that it demonstrates the strength of multiple different materials and technologies coming together. And solutions like this could play a role in more sustainable, more affordable space exploration.

00:02:29:07 - 00:02:35:07

Peter Zelinski

This lathe tool holder is from Utilis, toolmaking company in Switzerland. Viewers who do machining might recognize it as a tool holder for small parts turning. It is 3D printed because of the internal geometry. The passages through the solid body of the tool that deliver coolant, deliver cutting fluid and direct it at two strategic locations simultaneously on the cutting edge of the tool. This was formerly made through a more complicated conventional process drilling intersecting holes into the tool and then sealing up the exits of those holes. It's 3D printed instead through a relatively new process, cold metal fusion. This is a sinter based process that relies on selective laser sintering. Basically, polymer is melted together as a way of fusing metal powder, fusing it into a pre-sintered green form that goes on to an additional sintering step where it realizes its full density and strength and hardness. The process is like binder jetting. But a difference with cold metal fusion is the polymer and metal is pre-mixed into a uniform consistency all throughout. The result, it is said, is the possibility for pre-sintered parts that are bigger and stronger, more resilient for rough handling during an industrial process and even machining in the green state ahead of sintering.

00:04:03:04 - 00:04:36:12

Peter Zelinski

This toolholder is made of M2 Steel. Cold metal fusion is an invention of an alliance of companies, and companies affiliated with that alliance are able to use the process now. So this tool holder is manufactured by MIMplus using a selective laser sintering machine from Nexa3D. MIMplus says they could produce as many as 50 tool holders at a time, all in one build, 30 tool holders per build is more typical production pacing. The tool holder used to be made through a more conventional process. But simplifying manufacture ring with this additive approach has reduced the production cost for this tool, reduced it by about 20%

00:04:49:11 - 00:05:08:05

Stephanie Hendrixson

This next part is a micro 3D printed electrical connector. So this is a really small part. In the booth I was actually looking at it through a microscope to see some of the features. It has walls that get down to .1 mm in places. It's got these tiny little mounting holes. This is a part that would be really difficult to make through micro machining. You'd have the danger that the drill can just rip straight through the material. It would be challenging, if not impossible, to 3D print directly in metal and micro molding wasn't really an option because the part needs to be conductive. So the solution instead was to combine a couple of different techniques here.

00:05:24:13 - 00:05:31:00

Stephanie Hendrixson

So the body of the micro connector itself was 3D printed by Boston Micro Fabrication or BMF. This is a company that provides technology specifically for micro 3D printed parts like this. It was printed in layers of about 20 microns out of a heat resistant material. And then they still needed to add the conductivity. So that was accomplished through a company called Horizon Micro Technologies. They have a proprietary process for coating small parts like this with very thin layers of copper. So one or two microns of the copper material.

00:05:56:01 - 00:06:12:11

Stephanie Hendrixson

And I saw other examples of parts in their booth where the part was fully encased in copper. But as you can see with this electrical connector, they are also able to really precisely control where the material goes. And so for this part, they were able to add the copper just where they needed just to get the functionality of this connector, while also being able to easily and quickly 3D print the rest of the body out of a heat resistant polymer.

00:06:19:20 - 00:06:51:10

Peter Zelinski

This spoiler for a yacht is a large polymer component 3D printed through robotic deposition. Robots as a system for large format additive manufacturing was something that was definitely prominent at Formnext this year. The robot system that made this part is from Caracol and Caracol says the yacht industry is one example of a sector that is aggressive in their application of 3D printing for very large parts. There are a lot of reasons for this. Yacht makers need lightweighting. They deal in customization a lot and production quantities are relatively small. This part was 3D printed out of glass filled ABS, then followed by gel coating and painting. This is just half of the part. They cut it in half to be able to show it at the show. The complete component is about five meters long. 3D printing it took 40 hours. If it had been made conventionally, it would have been an assembly of smaller molded components. To produce it instead by 3D printing it in just one gigantic piece cut lead time in half, cut cost in half, also.

00:07:36:20 - 00:07:39:08

Stephanie Hendrixson

There’s a connection to robots in our next part. This is a panel for the blade of a vertical wind turbine. So vertical wind turbine, don't imagine a windmill with blades rotating perpendicular to the ground. Imagine something that looks more like a store display with the blades rotating in parallel to the ground.

00:07:54:22 - 00:08:01:18

Stephanie Hendrixson

So this part was produced using both a 3D printed tool and 3D printing directly. It starts with a flat sheet of clear polycarbonate that is laid over a vacuum tool. The vacuum turns on and it sort of molds the polycarbonate into the proper shape. And then this hexagon pattern is 3D printed on top to provide reinforcement and to make sure that it holds this shape. This part was a collaboration between several companies that were exhibiting at Formnext. So Airtech provided the material. It is a polycarbonate reinforced with carbon fiber, comes in a pellet format, and the same material was used both for the tool and the part itself. The printing was done on a machine from Hans Weber using a Kuka robot to achieve this complex geometry. It might look simple, but in fact the height of that structure is changing all across that curve because the leading edge of this panel needs to be really rigid and the trailing edge needs to be more flexible.

00:08:51:03 - 00:09:13:11

Stephanie Hendrixson

And so to control for all of this, AI Build’s software was used to generate the tool paths and do the slicing for this component. So the entire hexagon structure can be printed in about 2 hours and they chose to 3D print it this way using that sheet of polycarbonate because it was lighter weight than it would have been it to 3D print the entire blade in one go. And so this was an illustration of not only how you can reduce weight and combine 3D printing with other types of technologies, but also a demonstration of how 3D printing could be applied to reinforce or enhance existing parts.

00:09:26:14 - 00:09:35:10

Peter Zelinski

Bright Laser Technologies was showing this bicycle component. This is a brake cable guide that attaches to the bike frame. It's a redesigned version of this part that takes advantage of the possibilities of additive manufacturing. The curving form of this component conforms to the curve of the bike frame and enables a stronger weld for attaching it to the frame. This component is produced by bike part maker in China, Titan Super Bond, or TSB, and TSB uses a Bright Laser Technologies S400 Laser powder bed fusion machine. The machine has a build area of 400 millimeter by 250 millimeter and TSB just completely fills up the build plate with this part. It's made of titanium and one build produces about 500 of the part. The net result of that is that the individual share of 3D printing time for each individual part is pretty small. Build time translates to a 3D printing time of about a couple of minutes per part.

00:10:35:10 - 00:10:38:17

Stephanie Hendrixson

These parts are custom ostomy bag connectors. Ostomy bags collect waste outside a person's body. If they're not able to do it themselves, their used in cases where patients are being treated for things like Crohn's disease, colon cancer, lots of different intestinal disorders. And so there are 15 million people in the world that use these bags on a daily basis and leakage is a big problem and they tend to leak right at the connection right where the bag is joining the person's body. And so a group of students at the Elisava Barcelona School of Design and Engineering decided to solve this problem. They came up with this product that they call Odapt and they 3D print customized bag connectors based on the smartphone scan of the patient's body. And so these parts are made on a 3D printer from Linxster It's a French company that has developed printers capable of extruding silicone materials. The printers have two heads, so one for the silicone and one for a support so they can get more complicated shapes from these materials.The material used in this application is a silicone that was specifically developed for medical and health care applications, and it is safe for use against human skin. So to print each one of these connectors takes about 35 minutes. It uses only about eight grams of material. And I thought this was just a super cool application, not only for the quality of life benefits for patients using this, but also the chance to get a customized medical device in under an hour.

00:12:00:08 - 00:12:28:15

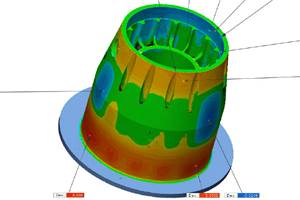

Peter Zelinski

This is a cold plate to maintain the battery temperature for the battery of an electric vertical takeoff and landing craft, an eVTOL or an air taxi. This cold plate is actually a quarter of the complete plate. It was sectioned off so that we can see inside and see the kind of compactness and lightweighting that is possible from heat exchangers using very thin fins spaced very close together. This is an aluminum part. It was 3D printed on a machine from EOS. It was made by Conflux. Conflux is a company that specializes in heat exchangers made through additive manufacturing. It designs the heat exchangers, but also modifies additive manufacturing equipment and engineers additive manufacturing processes, all aimed at getting the most possible heat transfer within a given volume of a mechanical system.

00:13:02:01 - 00:13:30:19

Peter Zelinski

So this cold plate, it uses fins that are 150 micron thick. They are spaced 250 micron apart. The cold plate itself is 1.3 centimeters thick. CEO Michael Fuller was telling me that they've since improved the design and the process for this component and they believe they can get it thinner probably 1.2 centimeters. A glycol solution flows through this plate to provide the cooling. The plate is 3D printed standing on end, and many of them are 3D printed at once that way, on end, side by side by side by side. So many of them that the build volume is 60% full with end use components. The flatness and parallelism of this particular part are also important. A flatness tolerance of 40 micron, parallelism of 50 micron. Post-processing steps achieve those tight tolerances, but in order to get there, the part has to be very square, very straight, coming off the 3D printer.

00:14:12:18 - 00:14:33:20

Stephanie Hendrixson

So that's it for this episode of The Cool Parts Show but that's not all of our Formnext coverage. We have videos that we filmed on site at the show which we'll link to in the show description. We have a forthcoming episode of a AM radio or podcast, which is all about what we learned at Formnext, and you can find photos, videos more from the show at our website AdditiveManufacturing.media.

00:14:33:20 - 00:14:35:06

Peter Zelinski

Thanks for watching

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreHow Does Heat Treating Affect Machining Considerations for a Metal 3D Printed Part?

This picture of part distortion in additive manufacturing illustrates the kind of effects that part design or machining stock allowances need to anticipate.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More