For a precision metal component made through additive manufacturing, the order of operations is not 3D printing then machining. There is almost always another operation than these. That is, the sequence proceeds from 3D printing to some form of heat treating (often hot isostatic pressing) to CNC machining, and the middle step can have a determinative effect on part geometry. Metal additive manufacturing service provider and CNC machine shop Wagner Machine has taken to scanning practically every one of its AM parts after it returns from heat treating because, in the words of CEO Kurt Wagner, “It is amazing how little information is out there on the effect of heat treat on additive parts.” With more data comparing parts before and after heat treating, the company hopes to be able to better predict heat-treating-induced distortion. The company CEO offers this picture of a recent AM part to illustrate the kinds of effects heat treating can have on the dimensions of a component that was true to form immediately following laser powder bed fusion.

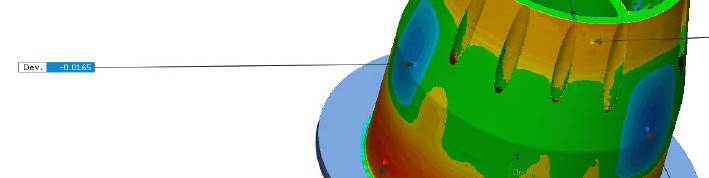

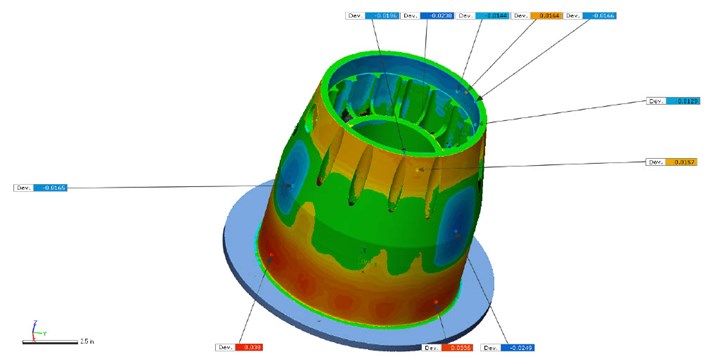

Scanning a part after heat treating and comparing the scan to the original CAD file reveals the kind of distortion that heat treating can bring about. Click on the image for a larger view. Credit: Wagner Machine.

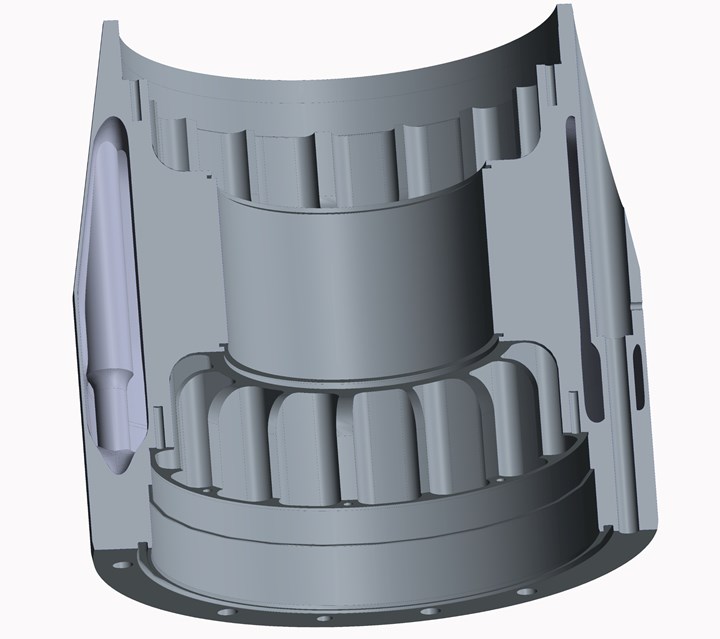

Wagner Machine made this microturbine generator housing for its customer KW Micro Power out of aluminum alloy F357 on a Sapphire metal AM system from Velo3D. The part is about 9 inches in diameter by 9 inches tall, and it features large open spaces inside its form — open regions 6 to 7 inches high — through which fuel flows to cool the part. The Wagner team recognized that these unsupported openings increased the margin for potential distortion.

“Usually we leave 1 mm of extra stock to ensure there is at least 0.5 mm for finish machining, but on this part, we left 1.5 mm,” Kurt Wagner says. That proved to be the right call, because while this part did distort in the way expected, it distorted by an amount greater than expected.

To understand part behavior in laser powder bed fusion followed by heat treating, Wagner Machine measures post-heat-treat parts using a scanning system from Creaform, then compares this geometry to the original CAD file. The comparison view of the microturbine housing in Geomagic software from Oqton maps the discrepancy. The blue “bruises” on the outside of the part show where the discrepancy after heat treating, including hot isostatic pressing (HIP), is particularly large. To a slight degree, the outer walls over the open internal regions caved in. That is, they sank by up to 0.0249 inch (0.632 mm).

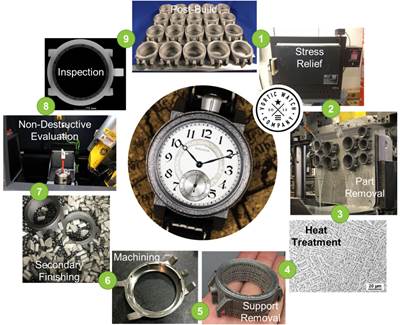

Here is the housing component after heat treating and machining. The holes through the part helped support its shape, and adding more of these might have been the answer if distortion had been greater.

However, they did not sink in uniformly. The scan reveals an interesting unintended effect of an additional feature of the housing. Fastener holes running through the part essentially act as tent poles, holding the outer walls in place. If the distortion had been greater, says Wagner, this might have been an even more meaningful discovery.

“Because we left 1.5 mm of extra stock, we still had enough margin to clean up the part and correct the distortion through machining,” he says. Wagner Machine offered to add additional internal supports to help support the shape of the part in future builds, but KW Micro Power said this is unnecessary. Part roundness was maintained through machining, and the part’s functionality was unaffected by the amount of distortion observed. (Bowing out, rather than in, would have been a different matter.) Still, says Wagner, the results stand as an interesting picture of the dynamics of part geometry introduced by heat treating an AM part, and why design for AM has to anticipate not just downstream CNC machining, but also the form of the post-heat-treat workpiece that will go to the machining operation.

Microturbine Relies on 3D Printed Housing to Preheat Fuel

This article is a follow-up to an earlier piece on the KW Micro Power housing made through additive manufacturing. Here is the original article.

Related Content

Zeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read More3D Printed Metal Component for CNC Machining Center: The Cool Parts Show #47

Machine tool maker DMG MORI improved this coolant delivery adapter by making the part through additive manufacturing instead of machining. One of the viewer-chosen winners of The Cool Parts Showcase.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

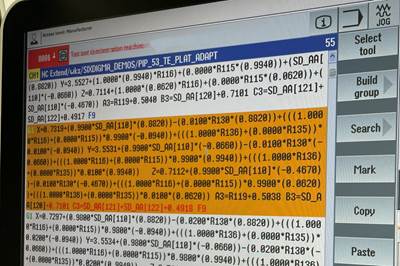

Will AM Help Bring a New CNC Programming Paradigm?

Complex workpieces such as AM parts present demanding toolpath challenges in machining. The precision is there to meet the challenges — we just need the measurements and methods to use it.

Read MoreMicroturbine Relies on 3D Printed Housing to Preheat Fuel

The aluminum housing designed with nTopology and made on a Velo3D laser powder bed fusion system helps realize what its creators say will be the highest-power-density small turbine yet produced.

Read More