7 Important Ideas on Postprocessing in AM

Additive manufacturing is defined by 3D printing, but it is more than this step. For almost every AM production part, steps after the 3D printing operation are essential to complete the part and realize its value. Here are several thoughts.

Share

-

Postprocessing parts made through 3D printing involves more than touch-up. The way to think about the steps that follow 3D printing is value-adding.

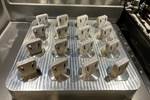

Support structure removal is a postprocessing need for metal parts made via powder bed fusion. Source: Rivelin Robotics

- Automation of postprocessing is the step needed for additive manufacturing to deliver fully automated component repair.

- Automation of postprocessing steps for metal AM parts calls for robotics that, to some extent, can operate with the sensitivity of a craftsperson.

- Depowdering is a crucial postprocessing step that often requires process engineering. Depowdering this component that was made additively calls for a special tool also made additively.

- As geometric complexity advances, the sophistication of cleaning needs to keep up.

- Postprocessing is advancing through partnerships. A few examples: Saint-Gobain and AMT, AddUp and PostProcess Technologies, EOS and PostProcess Technologies, Stratasys and DyeMansion.

- Coming soon: Watch for coating, plating and other surface improvements to AM parts.

Related Content

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

-

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.