New parts made from the same design are all alike, but every worn part is worn in an individual way. That distinction accounts for why remanufacturing is a greater process engineering challenge than the original manufacturing.

Optomec, the maker of metal additive manufacturing equipment based on directed energy deposition (DED), has come to understand this challenge as it applies to one category of parts in particular: the blades in aircraft engines, including compressor and turbine blades. The company’s technology not only includes an efficient platform for applying new metal to repair and restore worn or damaged blades for aircraft engines, but also includes software capable of interpreting vision measurements of a worn blade to generate deposition paths and weld parameters tailored to adding just the material needed to fix that particular blade.

Using data from a vision system, the DED cycle adapts material deposition to the form of each worn blade. This goes a long way toward automating blade repair, but realizing a fully productive turnkey solution required other operations to be automated as well. Photo courtesy of Optomec.

The need for this service is large. A considerable portion of aircraft engine manufacturing is remanufacturing. Blades in jet aircraft are wear items — heat and abrasion wear them, and engines are routinely repaired for this reason. According to Optomec president and CEO Dave Ramahi, maintenance, repair and operations (MRO) services for engines represent about a $50 billion market today, and the DED opportunity for MRO as it applies to jet engine blades is apt to provide more than a $1 billion market for machinery with rising air travel in the years to come. This is because DED can go a long way toward meeting the growing need by automating blade repair, with the metal 3D printing operation providing an alternative to work that has historically been performed through manual welding.

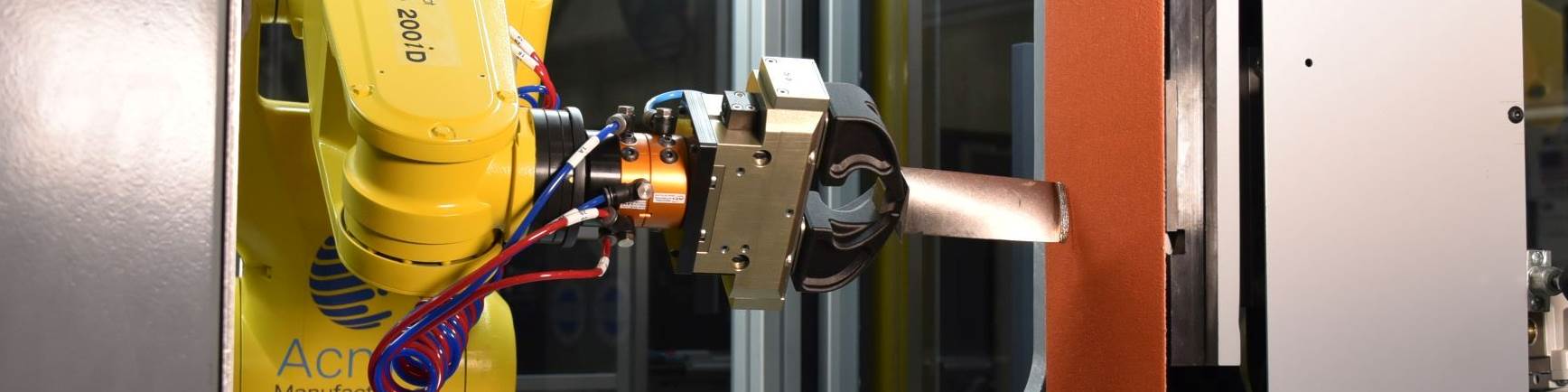

But here is the challenge: “We saw that, for additive to maximize penetration with this opportunity, it needs to automate the entire blade repair process, not just adding material,” Ramahi says. Metal deposition leaves overstock that has to be removed, with the surface blended to match the blade form, and these steps, too, are traditionally performed via skilled human labor. To automate these steps, the DED machine maker needed the help of a technology provider with expertise in adaptive and automated metal removal. Optomec found that in Acme Manufacturing, a specialist in material removal applications built around robots. A two-year development effort between the two companies has now resulted in an AM cell able to automate the full sequence of operations needed for blade repair.

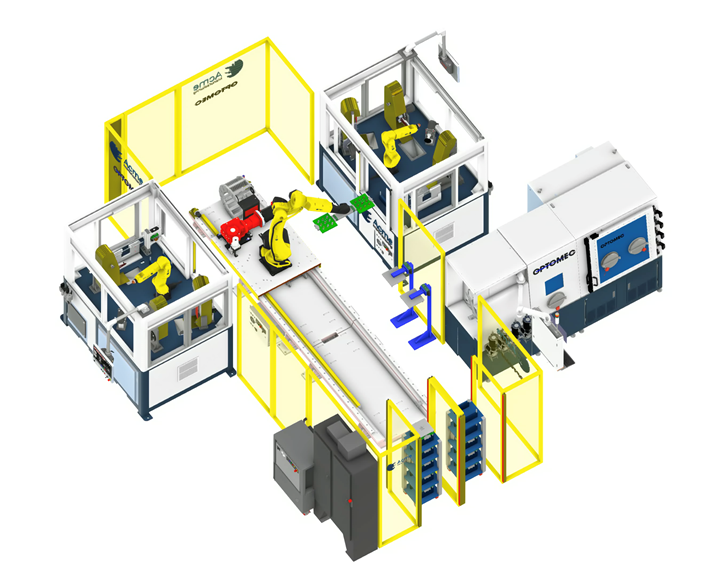

Optomec and Acme collaborated to develop a blade repair cell combining automated metal deposition with automated abrasive material removal to both prep the blade for DED and blend it to its finished form. Illustration courtesy of Acme Manufacturing.

The cell carries a worn blade through all of these steps in a completely unattended process. Plans for future development of the cell include adding capabilities for inspection, edge trimming and polishing. Illustration courtesy of Acme Manufacturing.

With this new cell, aircraft engine blades that have become unique and different due to individual distortion, damage and wear can now be mass-repaired automatically. The one-machine, multi-robot cell runs largely unattended, and can repair blades at the rate of 85,000 per year, the companies say.

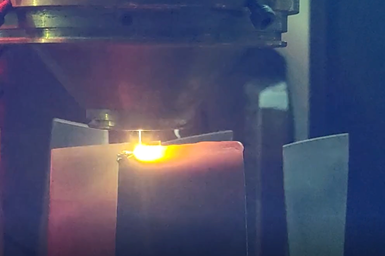

Here is precision grinding of a blade immediately after 3D printing via DED to add material at the tip. Programming this operation relies on understanding the performance of the engineered abrasive and the pressure with which the robot should apply the part.

Commercial air travel expansion promises to strain aircraft MRO, and this cell offers a timely solution. Yet it is also significant for what it illustrates about the role and promise of AM. Specifically, the cell is a working demonstration of all these points:

- Additive’s promise covers not just new parts, but also repair of existing parts.

- Additive manufacturing is more than 3D printing. To scale, it needs to successfully incorporate downstream (and in some cases upstream) steps as well.

- AM and robots interrelate. In this case, they go together because of material removal. Robotic material removal as it applies to hard metals is generally limited to fine grinding, but this is perfect for AM, which produces near-net-shape parts that need only this. Meanwhile, robotic finishing more easily lends itself to an adaptive process accommodating individualized part repair.

Here is more about the jet engine blade repair cell and how it operates:

Blade Running

Robots account for various steps in the cell. Three FANUC robots together provide for both part handling and abrasive material removal.

G.A. “Fritz” Carlson III (right) is fourth-generation owner of Acme Manufacturing. I visited Acme to better understand the robot operations of the cell. Acme is a FANUC robot integrator specializing in the use of robots for material removal.

The material removal is Acme’s expertise. “This is basically what the company’s focus has been from the beginning,” says president and CEO G.A. “Fritz” Carlson III, and that beginning goes back a long way. Carlson is the fourth-generation owner of the family business, founded in 1910. Since that founding, it has specialized in custom machines for finishing operations such as grinding, polishing, buffing and deburring. In more recent decades, it has applied its understanding of abrasives and motion and pressure control to robots in addition to dedicated machines. In the automated blade repair cell, robotic material removal steps come before the deposition, to grind the blade’s tip in preparation for DED, and then after it, to grind and blend the added material. Each of these steps involves a robot positioning the blade against an abrasive belt at a pressure tailored to the workpiece material and the known performance of the abrasive. The result is a repeatable solution for fine grinding of the hard titanium and nickel-based alloys used in aircraft blade production and restoration.

At the heart of the cell, the DED is performed by Optomec’s CS 250 Laser Engineered Net Shaping (LENS) machine, which uses a laser melting blown metal powder to apply new titanium and superalloy material to the blades. The compact machine was designed to provide an economical solution for aircraft blades, which are small enough that a pallet of 10-20 of them can fit into the machine’s 250-mm-cube build envelope. Watch DED for blade repair in action.

The actual metal deposition operation for the blades is fast, says Ramahi — 3 to 4 minutes per blade, with typically 12 blades run in a cycle. The purge time for the antechamber used to move parts in and out of the machine’s inert atmosphere is 15 minutes. As one pallet of blades is being cladded, another pallet enters the machine and will be ready for the next cladding cycle with no dwell time in between. The automated cell performs other operations on other blades during this time.

All the above describes hardware elements of the cell, but Ramahi stresses that measurement and software are why the system succeeds. No original CAD file drives the programming for repairing the blades, he says. MRO providers generally do not work from (or have) this original file, so Acme and Optomec did not look for it in the way they developed their system. Instead, calibration of the cell for any particular blade model requires just a “golden part” or ideal specimen, plus about 10 other specimens all classified as reparable. Once a blade type is “known” by these references, an automatic three-point measurement along any blade’s contour is enough for the robotic portions of the cell to identify that blade’s family and handle, prepare and finish it accurately.

The DED machine needs more information than this. At the Optomec machine, blades are measured using a vision system, and the company’s software for providing automatic, customized programming based on this inspection is called (cleverly) AutoClad. From one blade to the next, measurement of each individual form determines the DED laser power, laser spot size, powder feed rate, build speed and deposition paths to add the material needed to that particular blade.

The result of this adaptive programming of the material deposition, combined with the precision material removal through robotic abrasive grinding, is a level of control over the outcome of the blade repair that is tighter than the more manual blade repair process could have allowed. This too is an important point. The repaired blades are not new again — the number of repairs possible for any blade is limited to several service cycles and the repair area is different enough to be seen. However, blade repair in this cell is tightly repeatable. Further, each element of the cell has been certified by aviation authorities to produce repairs that meet flight-critical requirements, the companies note. That means the additive cell is not just ready and able to provide for expanded MRO capacity for engine blades, but it is able to provide restored blades returning to service that are more nearly alike from blade to blade than has been possible with repair operations until now.

Video: Additive Manufacturing for Aircraft Blade Repair

Optomec machines use directed energy deposition guided by optical measurement and automatic programming to repair aircraft engine blades. Here is a look at the 3D printing repair operation. WATCH

Related Content

The World’s Tallest Freestanding 3D Printed Structure

Dimensional Innovations paired additive and subtractive manufacturing to create a monument for the NFL’s Las Vegas Raiders new stadium. The “never been done before” project resulted in the world’s tallest freestanding 3D printed structure.

Read MoreTo Scale Additive Manufacturing, Separate Design and Production

Spokbee’s online marketplace is designed to ease the launch and sale of customizable, 3D printed products. Its flexibility comes from cloud-based CAD and a distributed network of service bureaus for production.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreRead Next

Air Force Awards $1.5M Contract to Optomec for Additive Repairs

Company says additive repair solution for F35 large titanium blisk has potential to reduce costs by 80% and save tens of millions annually.

Read MoreTaking Advanced Manufacturing Technology to the Site of Repair

The cost of a broken or malfunctioning part extends beyond monetary figures. Siemens Energy’s Additive Manufacturing Onsite Repair (ADDMORE) service aims to promote shorter repair times, longer intervals between service and increased availability of machines and spare parts.

Read More4 Ways Robots and 3D Printing Intersect

Four examples of how robotic automation and additive manufacturing both help and are helped by each other.

Read More