3D printing on its own is inherently automated, but the complete additive manufacturing process is not. The difference is postprocessing.

Rivelin Robotics debuted its system for postprocessing metal AM parts at Formnext, where the photos in this article were taken. Seen here are CEO Robert Bush (left) and CTO David Alatorre.

“When it comes to automating additive manufacturing, postprocessing is the biggest pain,” says Robert Bush, CEO of Rivelin Robotics. The UK startup has launched new, patented robotic technology focused on AM’s postprocessing needs.

Specifically, postprocessing for metal AM, notably laser powder bed fusion — meaning the fine material removal such as trimming, machining and polishing that is needed to complete these 3D printed metal parts. The reason these operations are so hard to automate is because of the finesse they often require. Where features are delicate or the cuts are light, machining has to be set up with care. Then, finishing has to be performed with a feel (literally) for not removing too much material. This is the reason highly unattended metal 3D printing operations are often followed by benchwork steps that are very hands-on.

Another reason postprocessing in AM is difficult to automate is that production volumes are low, while parts are complex. There is too little time or part quantity to allow for the complex programming work an automated finishing operation might require.

Vision measurement locates the part by aligning it with the digital model. Force-sensor feedback continually updates the part's position during machining and other operations.

Rivelin has addressed all these challenges to adapt robots to postprocessing work, but doing so required sensing and software capabilities the company had to develop for this very need.

The company’s name comes from its home in the Rivelin river valley, an early center of industrialization in England. Rivelin Robotics sees its work directly honoring and drawing on the heritage of this region, perhaps even more so than other manufacturing technology startups. The artisans working at the mills in this valley in earlier centuries performed their craft using hand tools applied with sensitive care to accurately fashion the items they made. Rivelin Robotics’ technology aims to allow robots to use what are essentially hand tools as well, by equipping them with an automated version of the craftsman’s sensitivity. Seeing the need for this was part of the breakthrough that brought the company to its unique system.

Positioning and Programming

“Our aim was always to automate postprocessing of metal 3D printed parts, but we hoped we could do this with existing robotics technology,” Bush says. One problem with that hope proved to be this: Tiny shifts in the positioning of workpieces during automated, unattended fine finishing can be enough to scrap an additive part.

Another problem: “Robot programming systems are not intuitive,” he says. For every new additive part, it would have been necessary for the user of robotic postprocessing to employ a specialist to program the routine — obviously impractical. Both these problems had to be solved.

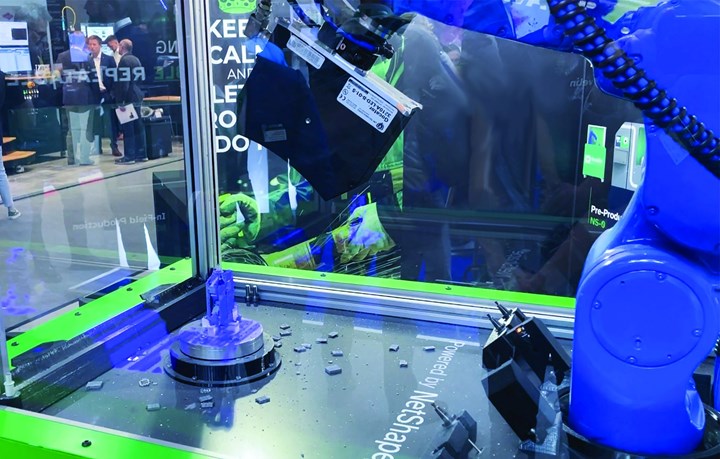

The robotic postprocessing system can complete a metal 3D printed part by switching between various tools to perform a sequence of operations.

The tools employed by the robot can also include those more conventionally associated with benchwork, such as a chisel for removing support structures. (Click image to enlarge.)

The solution to the positioning problem resulted in perhaps the most innovative aspect of Rivelin’s system. To solve the problem of force and displacement of the part, he says, “I thought we could use some kind of impedance control, but the feedback was not fast enough.” The solution that worked instead is found in control feedback relying on hardware installed beneath the rotary table that holds the workpiece. A six-axis force sensor continually accounts for the position and orientation of the part, and the robot’s control system uses this to continually update its own programmed reference frame. With this mechanism, overcutting during fine finishing essentially is not possible, because the coordinates that define the finishing moves adapt in response to even slight positional changes produced by real forces.

Polishing is another step that might otherwise be performed by hand that the unattended robotic system is able to perform accurately. (Click image to enlarge.)

The digital model of the part on which this movable coordinate reference frame is based is attained through vision measurement, another element of the Rivelin system. Vision plus force sensing together — sight and touch, basically — are what make the robotic system responsive like a craftsman.

And software makes the system practical, Bush notes. In the company’s software interface, surfaces of the part model are matched with tools in the robot’s kit, including saw, chisel, belt grinder, drill, end mill and so on. Feature-based programming for each of these tools then generates the code for the robot to perform the intended operation with that tool on the intended surface or feature. Developing this software was every bit as important as the force-and-vision system, he says, because programming would be a prohibitive step unless it could be made simple. In the interface as it now exists, programming the system simply requires recognizing that, say, a certain feature needs fine grinding, another needs to be cut precisely, and a remnant support structure needs to be chiseled away. The user matches features of the part model to different types of tools and operations to impart this intent, and that matching informs the autogenerated robot program.

The company has applied this technology to realize a small automated robotic postprocessing system for small metal additive parts, but there is nothing inherently size-dependent or size-limited about the technology, Bush notes. A robot from any vendor, in any size range needed for the AM parts in question, potentially could be applied within this system. Indeed, Rivelin’s initial aim to automate postprocessing using existing robot technology has been realized to at least this extent: The robot itself is the one standard, off-the-shelf component of the system.

Related Content

Aluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreRead Next

10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More