Additive manufacturing (AM) enables complex parts with tortuous internal geometries. However, for these parts to be made in real production scenarios, postprocessing techniques that can clean those complex features must keep up. For many manufacturers, automated cleaning solutions that can handle demanding geometries will be necessary to scale AM to production volumes. Vacuum Processing Systems, a company that has historically provided cleaning solutions for parts made through more conventional methods, has found that its Vacuum Cycling Nucleation (VCN) technique has applicability for those 3D printed parts with tortuous internal geometries and porosity. The parts cleaning process is capable of removing uncured photopolymer resins or unsintered metal powders from 3D printed parts with cycle times under half an hour from start to finish.

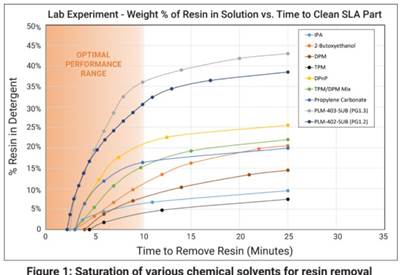

The VCN process causes nucleation to form around powder particles or other contaminants, which are then dislodged as the vapor bubble expands. Photo Credit: Vacuum Processing Systems

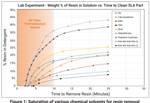

The Rhode Island-based company’s proprietary VCN technique clears excess material from internal chambers and small-diameter channels through the use of fluid in a vacuum environment. Once parts are placed inside the sealed vacuum chamber, the air is removed and the chamber is flooded with heated liquid (either isopropyl alcohol [IPA] for polymer applications or a mild soap solution for metals). Once the liquid gets above its vapor pressure, bubbles form — essentially “boiling” the cleaning fluid.

This double-cone was 3D printed from Inconel with only these four small holes to remove the powder from its interior. Photo Credit: Vacuum Processing Systems

The vacuum pulses on and off in 1.5 to 2-second intervals, allowing the fluid to flood the part before generating bubbles that drag the monomer or metal particles out from its internal geometries. Once cleaning is complete, the chamber is drained and parts are rinsed and dried still in the vacuum environment. The entire cycle can be completed in as little as 15 minutes.

Below is VCN in action cleaning a variety of parts. The Inconel double-cone part pictured here is shown starting at 1:01 in the video; this 3D-printed part was produced for NASA in a project funded and technically supported by DLA Aviation Hazardous Minimization (HAZMIN) and the Green Products Program (GPP).

Each pulse of the vacuum carries more powder or resin out of the part, which accounts for the cloudiness in the cleaning fluid. The cleaning cycles shown in this video were recorded using the company’s lab Vacuum Cycling Nucleation system with a glass chamber — useful for both tuning the cleaning “recipe” for each individual part as well as reporting results back to potential customers, says Joe Schuttert, sales manager. Vacuum Processing Systems supplies custom VCN machines that are tailored to each customer’s typical part size and other needs.

The self-contained systems enable users to automate the cleaning process while also providing safety and environmental benefits. The IPA used as a solvent for uncured resin is a potential fire hazard for instance, but in the VCN unit the fluid is isolated from oxygen and ignition sources, greatly reducing that risk. The fully enclosed units also help to minimize fluid loss over time and can include filtration and distillation to keep the fluid clean for long periods of time.

Though the Vacuum Cycling Nucleation process was not originally developed with AM in mind, it has proven to be applicable for cleaning porous parts like hip implants as well as parts with small internal channels, such as hypodermic needles and heat exchangers. Whereas other cleaning options like high-pressure air or water lose energy inside a tortuous path (making it more challenging to remove both the fluid and the waste), the vacuum pulsation applies energy internally for more efficient waste egress.

Related Content

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreUnderstanding HP's Metal Jet: Beyond Part Geometry, Now It's About Modularity, Automation and Scale

Since introducing its metal binder jetting platform at IMTS in 2018, HP has made significant strides to commercialize the technology as a serial production solution. We got an early preview of the just-announced Metal Jet S100.

Read More3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.

Read MorePivoting to Additive Manufacturing for Individuals and Organizations: AM Radio #29B

The pivot to additive manufacturing requires interested individuals as well as support from the top. In a recent episode of AM Radio, we discuss workforce development from the inside and strategies for implementing AM across an organization.

Read MoreRead Next

3D Printed Parts on the Mars Perseverance Rover: The Cool Parts Show #23

The Perseverance parts made through additive manufacturing are extreme examples of lightweighting. We have replicas of the 3D printed parts that were sent to Mars.

Read MoreA Conversation on Formnext: Trends in 2021, and Formnext USA: AM Radio #8

The Frankfurt, Germany, trade show resumed in-person in 2021 and laid the groundwork for future events in North America. AM Radio hosts Stephanie Hendrixson and Peter Zelinski discuss both in this episode, which includes a guest appearance by Gardner Business Media president Rick Kline.

Read MoreRealizing Efficiency and Sustainability Through Automated Postprocessing of Resin 3D Printed Parts

Workflow efficiencies and sustainability goals can be achieved together. An automated cleaning system and longer-lasting detergent allowed one manufacturer to reduce hazards, costs and time in its resin removal process.

Read More

.jpg;width=70;height=70;mode=crop)