HP, Materialise Integrate Technologies to Optimize AM Manufacturing Workflow

Working in combination with the Materialise CO-AM Software Platform, manufacturers can now link HP’s Multi Jet Fusion and Metal Jet technology to their existing production systems to optimize the additive manufacturing workflow from order entry to delivery.

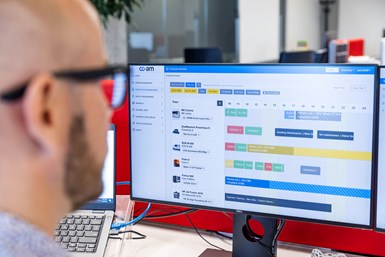

A seamless connectivity between HP AM technology and Materialise CO-AM enables users to create workflows that improve traceability, quality control and machine utilization. Source: Materialise

Materialise is collaborating with HP Inc. to integrate HP’s Multi Jet Fusion (MJF) and Metal Jet additive manufacturing (AM) technology into the Materialise CO-AM software platform. This collaboration enables manufacturing companies to raise the efficiency and quality of their 3D printing to match industrial requirements and use it for volume production of end parts.

“To scale additive manufacturing, the industry is in need of printers that are designed for high productivity coupled with an integrated end-to-end workflow solution — the partnership between HP and Materialise delivers this solution,” says Arvind Rangarajan, HP’s global head of Software and Data, HP Personalization and 3D Printing.

According to the companies, manufacturers recognize the unique benefits of AM, but face challenges as they onboard the technology. The speed of their 3D printing process may not hold up to volume production and they may have difficulties integrating the process with existing manufacturing technologies. To support these companies, HP delivers industrial 3D printing solutions that are manufacturing-ready.

In combination with the Materialise CO-AM Software Platform, manufacturers can link HP’s Multi Jet Fusion and Metal Jet technology to their existing production systems and optimize the AM workflow from order entry to delivery.

As an HP preferred partner, Materialise will provide the industry with an end-to-end manufacturing solution that is integrated with an additive technology which is designed for productivity and scale — the MJF and Metal Jet systems. As part of this partnership, HP will help customers identify meaningful use cases for the software platform, as well as showcase the solution at HP demo facilities and public events.

“Manufacturers are increasingly using 3D printing for end-use parts instead of solely in the prototyping and design phase,” says Bart Van der Schueren, Materialise CTO. “This partnership will help drive this shift by supporting more efficient, repeatable volume production.”

The seamless connectivity between HP AM technology and Materialise CO-AM enables users to create workflows that improve traceability, quality control and machine utilization. Optimized 3D print job management enables production leads to track planned and actual printer activities and optimize machine time.

To ensure continuous production, real-time machine monitoring provides operators and engineers with critical process data, including build status, material usage and machine sensor data. This data can be collected and stored in log files of 3D printed jobs to enhance traceability and quality control.

In addition to their 3D printers, Metal Jet users can connect process-relevant HP machinery to the CO-AM platform, such as powder management station, curing station and powder removal station. This integration enables Metal Jet users to streamline postprocessing of metal parts within the manufacturing process.

CO-AM includes Materialise’s leading data and build preparation capability from Magics, which connects to HP 3D printers via the HP Build Processor. Users benefit from a proven tool set to prepare their 3D printing jobs for all major AM technologies. Users can add workflow automation for repetitive tasks and use nesting to maximize the number of parts per job to increase machine utilization.

Additionally, CO-AM provides access to complementary solutions from Materialise and third parties, including CO-AM partner solutions for design automation, mass customization, automated labeling and various postprocessing technologies. CO-AM enables AM users to connect and manage technologies from different machine builders over one platform.

Related Content

Lightweight Components: A Paradox When Machining

Today’s computer software can just as easily generate lightweight shapes for subtractive processes as it can for additive ones, but it increases cost and waste to make them.

Read MoreTaking the Leap into Additive Manufacturing

SolidCAM’s partnership with Desktop Metal, and its in-depth experience in combined metal 3D printing and CNC finishing, is aimed at making additive manufacturing accessible and profitable for job shops and other manufacturers.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More