This morning at IMTS – The International Manufacturing Technology Show, HP announced the commercial availability of Metal Jet, its production solution for 3D printing of metals. The binder jetting platform is not a surprise — HP first announced its metal 3D printing technology at IMTS in 2018. But the Metal Jet S100 solution now available for commercial purchase looks and feels quite different from the machine unveiled four years ago. This summer, I visited HP’s 3D Printing Technology Center near Barcelona, Spain, to get a preview. As the result of development and collaboration with early access customers, the Metal Jet platform now offers something approaching an end-to-end solution for manufacturing of metal parts, emphasizing both digital and flexible production at scale.

“Metals in particular have been behind the curve of digital manufacturing,” says Ramon Pastor, global head and general manager for HP Metal Jet. “Plastics have advanced. Injection molding is very efficient and can be automated, but metal parts need five to six processes, and are dependent on skilled labor.” A global shortage in that labor means that metal part production often faces long lead times for machining and tooling, and its supply chains remain rigid, without recourse to move production or alter a design.

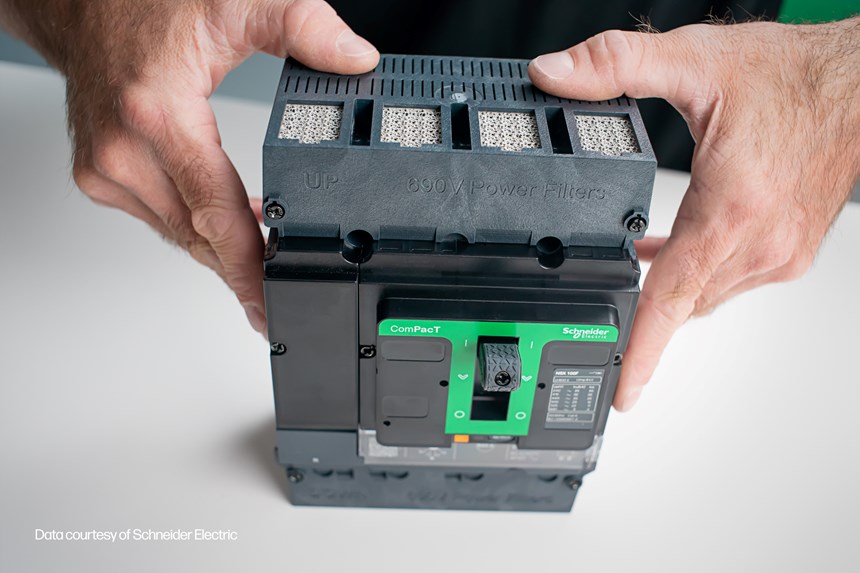

These Schneider Electric filters made by GKN showcase Metal Jet’s geometric capabilities, but are also wins for part quality, productivity and economics at scale. Learn more Thursday, September 15, when Michael Lotfy of Schneider Electric joins Ramon Pastor and Meaghan Ferris of HP on stage for the keynote of the Additive Manufacturing Conference at IMTS. Photo Credit: GKN

These Schneider Electric filters made by GKN showcase Metal Jet’s geometric capabilities, but are also wins for part quality, productivity and economics at scale. Learn more Thursday, September 15, when Michael Lotfy of Schneider Electric joins Ramon Pastor and Meaghan Ferris of HP on stage for the keynote of the Additive Manufacturing Conference at IMTS. Photo Credit: GKNMetal Jet is meant to face each of these challenges; if metal part manufacturing can become more automated and digital, while still enabling economic production at scale, then it can avoid lengthy delivery times while also supporting greater design flexibility and even distributed manufacturing. With these goals in mind, HP has put the emphasis on uptime and yield for this platform. Here is what I came to appreciate through conversations with the HP team about the development of this platform, and its potential role in metal part production.

Modular, Scalable Production Solution

First, it should be noted that the product on offer is not just a 3D printer, but a suite of modular equipment for production-scale metal binder jetting. Metal Jet S100 (“Solution 100”) actually includes four distinct stations, between which portable build units can travel (very much like the build units for the Multi Jet Fusion [MJF] platform that move between the printer and postprocessing station). With multiple printers and build units, customers can run continuous production and easily scale up. The components of the system are:

The Metal Jet S100 is not a single printer, but a full suite of equipment for metal part production. It includes (left to right): mobile build units, the Powder Management system, the Metal Jet 3D printer, the Curing Station and the Powder Removal system. Photo Credit: HP

- Powder Management system, which automates blending, sieving, and loading fresh or reclaimed powder into build units without human contact. A single system can serve up to six Metal Jet 3D printers. The S100 is compatible with standard metal injection molding (MIM) powders; thus far HP has qualified 17-4PH and 316L stainless steels, with additional steels, nickel and cobalt alloys, and other materials in the works.

- The Metal Jet 3D printer itself, which uses printheads similar to those applied in the MJF system to deposit binder into a bed of metal powder to build up “green” parts. The binder itself is an aqueous latex suspension or long-chain polymer. A distinctive feature of the printer’s operation is that it can jet the binder for each layer in two passes, which allows for greater infiltration into the powder; this approach combined with the binder chemistry provides greater strength to the green parts.

- A Curing Station, which uniformly heats the build unit to cure the binder. Post-cure, HP says its binder jetted parts contain only about 1.5% binder by weight, depending on geometry.

- The Powder Removal system, which uses ultrasonic vibration to remove and collect unbound powder from parts in a fully enclosed environment, so that it can be returned to the Powder Management system for reuse. Like the Powder Management unit, this system automates what can be a tedious and time-consuming step, allowing operators to focus on other tasks. And like the Powder Management unit, each Powder Recovery system can serve half a dozen printers; users can pick and choose the pieces of the solution they need, and scale accordingly.

Notably not included in the line-up is a sintering furnace, the necessary last step to fully solidify binder jetted metal parts. This is because the process is compatible with any commercial sintering furnace, from lab-sized units to large-scale production vacuum furnaces. Customers have the option to use equipment they may already have, or to outsource the sintering (the stronger nature of the green parts simplifies the prospect of shipping them for this step).

The modularity of the S100 is one of its key advantages. Users can scale up by adding the equipment as it is needed, and build out a factory such as this one suited to mass production. Photo Credit: HP

Users and Applications

The distinct binder chemistry and jetting process used in Metal Jet makes it possible to produce larger-than-typical components with this modality — exceeding 1 kg. This capability is no guarantee that prints will be economical at this size, Pastor says, but the range makes it possible to consider types of parts that would not previously have been a fit for binder jetting, or comparable processes like MIM. Like other forms of 3D printing, design freedoms are an advantage of the Metal Jet platform — but the company sees automation and efficiency as more significant.

Process step consolidation, rather than design freedom, is now the chief concern for metal parts producers.

“Customers are engaging not because of geometry, but because of process step reduction,” Pastor says. While binder jetting may require several stages, they are all part of the same additive manufacturing process and with a platform like Metal Jet can be automated and consolidated under the same roof; that means a faster, streamlined route to near-net metal parts.

Until now, fewer than two dozen companies have used the Metal Jet solution in testing. But the handful of these 22 companies that have been named publicly offer a glimpse of the kinds of users and applications HP anticipates. On the one hand, they are OEMs — Schneider Electric, Domin Digital Motion, Volkswagen and Legor. On the other hand, they are contract manufacturers — GKN and Parmatech. This is intentional, Pastor says.

While today most additive manufacturing equipment is owned by service bureaus and contract manufacturers, these companies tend to operate at a “tier one” level (GKN and Parmatech are examples of this), directly fulfilling orders placed by OEMs. Pastor (and fellow HP leaders) anticipate that the balance will shift as more OEMs become convinced by and committed to additive manufacturing, and at the same time, contract manufacturers will still remain important part producers. “We want to build factories,” Pastor says, and both these types of businesses — OEMs and advanced contractors — are well-positioned to adopt additive into full-scale production.

In most cases just one of these potential benefits is not enough reason to choose Metal Jet, but HP has collected a number of production part successes from its early access partners already that illustrate how they can work in tandem:

Metal Jet Early Access Partner Applications

Related Content

Casting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreHow Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MoreRead Next

More Than Meets the Eye to Cobra’s 3D Printed Putter

Cobra Golf drew attention in November 2020 with the launch of a limited-edition putter with metal 3D printed head. What this club says about product development, reshoring manufacturing and the future of consumer goods.

Read MoreWhat Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreTo Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

Read More

.jpg;width=70;height=70;mode=crop)