Robot Is Production Solution for Laser Metal Deposition

The move from prototyping to production might involve a move from machine tool to robot, but development work between Formalloy and the robot suppliers means the process and programming do not have to change.

In metal additive manufacturing (AM), the move from prototyping to production might involve a very different machine platform, but the process does not have to change.

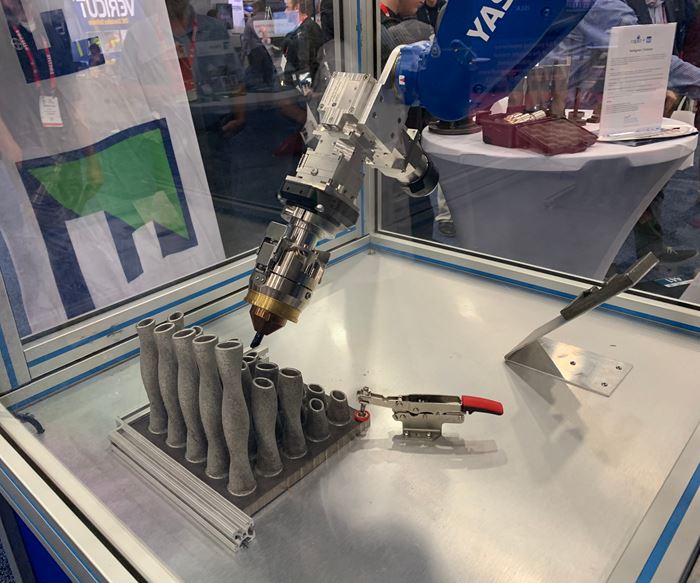

Formalloy was showing the demonstration seen in the photos above at the recent Rapid + TCT event. This demo of a robot using the company’s laser metal deposition (LMD) head ties together much of our recent coverage, including various posts on AM and robots, one in particular on metal AM with robots, and an article and video interview about Formalloy’s pursuit of the promise of LMD.

According to Formalloy cofounder Melanie Lang, a metal-deposition-based production process might be proven on a stand-alone machine tool, but in production, a robot might be the most versatile solution. The company has worked with robot supplier Yaskawa to enable a robot to run the same G-code program that might have run first on the LMD machine. As our article describes, the head is even easy to change from one to the other.

For more about this year’s Rapid + TCT, check out our video coverage and our 10 impressions of the show.

Related Content

-

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

-

10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

-

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.