Video: Formalloy Finds Flexibility in Laser Metal Deposition

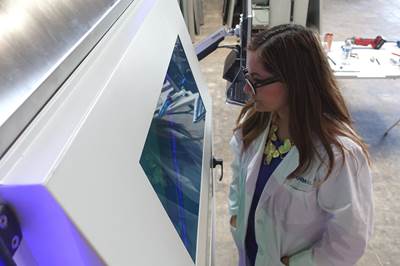

Melanie Lang, founder and managing director of Formalloy, talks with Senior Editor Stephanie Hendrixson about laser metal deposition (LMD) for multiple materials and applications.

Laser metal deposition (LMD) is one of the older forms of metal 3D printing, and tends to be associated with repair applications and large parts not requiring high levels of detail. But Formalloy, a California-based startup, sees things a little differently. The company has developed its own LMD head and systems, and is demonstrating that the technology can be used for fine detail, cladding, material gradients and more—including those traditional repairs and large-part applications.

I sat down with Melanie Lang, co-founder and managing director of the company, to learn about the opportunities that Formalloy sees for this flexible additive manufacturing process. Watch below or read on for the transcript. Learn more about Formalloy’s LMD technology in this story.

Transcript

Stephanie Hendrixson, Additive Manufacturing

I'm Stephanie Hendrixson with Additive Manufacturing magazine. I'm here with Melanie Lang. Melanie is the co-founder and managing director of Formalloy. Formalloy is a California-based startup that provides laser metal deposition (LMD) technology. Why did you choose to focus your company on this specific technology?

Melanie Lang, Formalloy

I wanted to focus on an additive technology that would be scalable for production and also have multiple applications. With laser metal deposition, it's very scalable so you can do small parts, you can do prototypes, but you can also do very large parts and full-scale production parts.

The LMD technology can be used for the additive applications but it can also be used for repair applications and cladding or feature addition. So sometimes it's easier to bring a process in-house that you can use to repair existing parts and then maybe expand to the other applications.

Melanie Lang

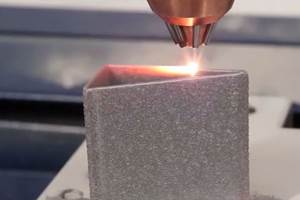

Another one of the advantages of this process is the ability to do gradient or multi-material parts so I have a couple examples with me where, in a single build we've built a fully dense part. This one has three materials in it. We've used Inconel 625, 718 and Stellite 6 to finish it off. This other part is Inconel with a copper top on it. Gradients can be used for combining multiple parts into a single build. It can be also used for unique properties that you can't achieve any other way. For example, thermal properties. You might want the thermal properties of copper but need the strength of Inconel. Now you can build those materials into a single part.

Stephanie Hendrixson

What are some of the challenges of building one material onto another? And how do you deal with that?

Melanie Lang

One is that all metals do not necessarily like each other. Either they won't bond together or they form a brittle inter-metallic causing them to break apart. That's another advantage of being able to do a gradient. Let's say you want to join two dissimilar metals which are very difficult to join. For example, stainless steel with titanium. With our gradient capability we can use a third metal between those two in a gradient method so that way you can transition from steel to titanium with using an intermediary material between the two.

Stephanie Hendrixson

One of the other things that you offer with your systems is the blue laser. How does that help you with working with different types of materials?

Melanie Lang

the blue laser is a shorter wavelength than the more traditional IR laser that's used for manufacturing. That shorter wavelength allows for better absorption for really any material that has kind of a gold look to it. So gold, bronze, copper, all have that advantage with the blue laser. They like to reflect the IR wavelength a lot and they absorb the blue or short wavelength laser really well. We've made that as an option with our systems so they can have an IR laser, a blue laser or both for ideal processing no matter what material you're using.

This is an example of a rocket nozzle component. For additive applications, we can build very complex geometries like inlets ones that you see in this wall here with our five-axis of motion capability. These stripes around here are actually clads that we added with a second material just to show the bi-metallic capability as well as the ability to clad, which you might want to do to add strength or for corrosion or wear resistance for example.

Stephanie Hendrixson

So you've provided machines, and/or made parts for, organizations like NASA and the Marine Corps, these are very real industrial parts that are going into very demanding environments. How do you ensure that you're getting a good build every time?

Melanie Lang

We do a lot of metallurgical studies and process parameter development before we build a final product for a customer or for a feasibility study or a R&D project to ensure that it's a fully dense part that's going to provide the strength that's needed for the application. Another way that we ensure, during the build, that it's good quality is with the technology that we call Dynamic Layer Selection. As we've filled each layer of the part we then scanned the part and we create a topographical map of what that layer looks like. So you can use that to measure your exact layer height and then any discrepancies with that layer. The user can then choose whether it's best to stop the build and start over, depending on how far out of tolerance it is. Or they might be able to correct that layer before moving on to the next layer.

Stephanie Hendrixson

Where is laser metal deposition heading? What is the next step?

Melanie Lang

I think the big advantage or next step for LMD is really to help with the transition to full-scale production. It's pretty common to find additive applications for tooling and prototyping. Now we'd really like to see the additive technology being used in full scale production parts, very large parts and even some large volume parts. And we can do that with fast deposition rates and with the scalability.

Stephanie Hendrixson

Melanie, thank you for joining me and talking about laser metal deposition and its potential for production applications.

Related Content

Robot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Read MoreDEDSmart Tool Harnesses Data in Real-Time for Build Quality Verification

FormAlloy Technologies’ DEDSmart technology for autonomous DED builds and build data logging utilizes enhanced in-situ monitoring and control, and the power of data, to complete builds autonomously while data logs are automatically exported enabling Digital Build Certification.

Read MoreInfrared Camera Supports Real-Time Process Control for Laser Metal Deposition and Cladding

New Infrared Technologies’ Clamir system provides continuous meltpool monitoring for cladding and directed energy deposition 3D printing.

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read MoreRead Next

Directing the Future of Laser Metal Deposition (LMD)

Formalloy is proving that LMD is for more than repairs and large parts. Fast deposition rates, fine detail capabilities and multimaterial support promise to change how parts are designed and made.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)