Is additive manufacturing (AM) in competition with other, more established manufacturing processes?

To be sure, it is. A part that in the past might have been made through molding or machining could be a candidate for 3D printing today. Indeed, the range of production work for which AM is a competitor to established manufacturing processes is growing.

And if this competition has sides, then I am on both. Along with my role for Additive Manufacturing, I am also part of the staff of Modern Machine Shop, which covers CNC machining — an established process. One thing this dual role helps me see is that the terms of the contest are not fixed on either side. Where there is an old technology and a new one, observers’ attention naturally tends to go to the new technology’s advances, spotting how quickly those advances proceed and how much the technology changes with each leap. What is easy to overlook is that the established technology also may change. This is happening in manufacturing; the changes come more slowly and may be less dramatic, but conventional manufacturing processes are advancing, too. The newcomer, AM, is in no way assured of a straight path to success.

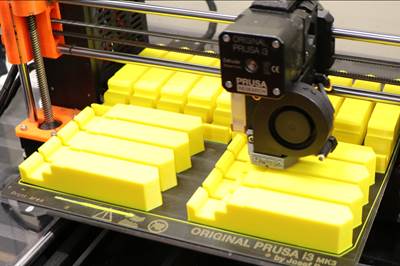

IC3D founder Michael Cao talks to me about 3D printed molds for vacuum forming — a process that is a natural fit for 3D printed tools made of polymer because the heat and pressure are relatively low. IC3D is succeeding with AM for tools with more demanding requirements as well.

But here is the thing: One of the most important ways conventional manufacturing is advancing today is through the application of 3D printed tooling. Thanks to 3D printing, tooling for established manufacturing processes can be made cheaper and with less lead time, and in many cases can be made to perform better than standard tooling made in conventional ways. When we speak of 3D printed tooling, what we are really talking about is the way AM is aiding and advancing conventional manufacturing.

So, AM is also on both sides, or so it would seem. AM for tooling is essentially in competition against AM for production parts.

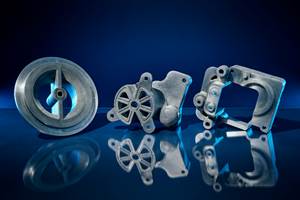

It seems fitting, then, that as an immediate follow-up to our recent collection of stories all about production, we have recently posted various stories all about tooling. Recent pieces cover the use of 3D printed tooling for casting, injection molding, foam molding, low-temperature molding, assembly and machining. As just the range of these successes shows, tooling is every bit as impactful upon the future of production as the chance to make production parts through AM, because tooling enhances the possibilities of operations that are well-known and widely used.

Are there really different sides, then? Is there really a competition? Some tooling examples bring this matter circling fully back onto itself. For example, injection molding (a conventional process) gets more capable in some cases — through short lead times or conformal cooling — thanks to tooling made through AM. However, to make mold tooling this way represents AM succeeding over machining, because machining (another conventional process) is the way molds are usually made. In other words, the conventional process wins because AM wins over a conventional process. As this confusing summary reveals, the analogy of a competition becomes particularly tortured at this point.

The entire question deserves to be considered in a different light. Is AM in competition with other, more established manufacturing processes? To be sure, it is not — this isn’t the right paradigm after all, as the impact of 3D printed tooling makes clear. The larger and truer paradigm is this: Manufacturing is advancing, and AM is powering the advance.

Related Content

Is 3D Printing Competing with Casting? AM Radio #27B

On this episode of AM Radio, we discuss two examples of companies that are shortening supply chains by using 3D printing instead of casting.

Read MoreCasting With Complexity: How Casting Plus 3D Printing Combine the Strengths of Both

Aristo Cast is advancing a mode of part production in which casting makes the part, but 3D printing enables the geometry.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read MoreRead Next

10 Examples of 3D Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D printed tooling.

Read MoreHow Flowable Metal Paste Could Deliver on 3D Printing's Promise for Mold Tooling

A new 3D printing process that shapes extruded metal paste before sintering can produce fine detail and surface finish suitable for injection mold cores and cavities with limited or no additional postprocessing.

Read MoreFord is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

Read More