Additive manufacturing is a disruptive technology anywhere in the world, one that requires careful consideration and implementation. But in India, where manufacturers tend to be highly conservative and risk-averse, AM can be a particularly hard sell.

“Every organization has its own understanding of additive manufacturing,” says Ankit Sahu. “The most important thing for us is understanding the customer and their challenges.”

Sahu is owner and director of Objectify Technologies, a company he founded with his brother in 2013 that today is possibly India’s largest additive manufacturing service center. The company offers metal and polymer AM in the form of laser powder bed fusion, stereolithography and selective laser sintering (SLS); industries served include space, aerospace, and oil and gas (partly because of the company’s close proximity to customers in the Middle East). About 30% of Objectify’s revenue comes from exports; the rest is made up of domestic business, a fact that poses unique opportunities and challenges.

“Awareness of the technology and its benefits is still a challenge we face. There is still skepticism in AM.”

While manufacturers in India are embracing additive more than ever, “Awareness of the technology and its benefits is still a challenge we face,” Sahu says. “There is still skepticism in AM. Manufacturers in India have less risk-taking ability and decision making is slow.”

But a disruptive technology like additive requires tolerance for risk. To overcome conservative business practices, Objectify Technologies approaches each new job as an opportunity to win customers’ confidence and make that risk-taking worthwhile. Much of the way the company operates is geared toward overcoming hesitation regarding AM — and these tactics could apply for other AM users globally.

1. Offer co-development on new parts.

To counter skepticism and ensure successful implementation, Objectify Technologies takes an active role in helping customers develop parts for AM. That includes everything from a part’s initial DFAM, to printing and postprocessing workflows, to supporting customers through qualification.

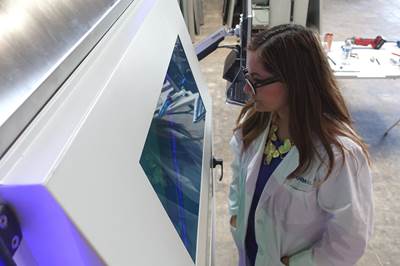

This 3D printed impeller for a centrifugal pump replaces an investment casting. The AM development of this part took about two and a half weeks, less than the six to eight week lead time for the casting. Photo Credit: Objectify Technologies

In the case of the impeller for a centrifugal pump pictured above, for instance, Objectify found that the default parameters for printing stainless steel 316L resulted in a long build time and increased risk of quality issues in the print. The company had to develop new parameters for the material, using thermal simulation through Simufact to identify probable areas of thermal deformation in the unique closed impeller geometry. Objectify was able to develop an additive manufacturing strategy and deliver printed parts within just a few weeks, compared to the two months’ long lead time the customer was previously experiencing for investment casting.

The impellers are printed on an angle with support structures using Objectify’s EOS M400-4 laser powder bed fusion 3D printer. Photo Credit: Objectify Technologies

Taking the time to develop applications like this helps to ensure success, key to persuading skeptics of AM’s value. A small percentage of customers will take the production in-house after this process development, but in about 95% of cases, Objectify continues to manufacture parts it has developed. Its sweet spot is serial production of batches ranging from 50 to 500 parts per year, Sahu says.

2. Provide digital inventory for legacy parts.

Objectify is building a digitized library of service parts for customers, particularly in oil and gas, allowing them to access replacements quickly and without investing in inventory that might be wasted. Additive manufacturing makes it possible to reproduce out-of-service parts as they are needed, but also to improve those original designs and help customers realize the benefits of AM. Still, this is a negotiation.

“Customers initially ask for apples-to-apples parts,” Sahu says, but as Objectify engineers illustrate potential benefits in terms of weight savings, assembly and other efficiencies, legacy parts often receive design improvements over the conventional originals.

3. Think in terms of “like” parts.

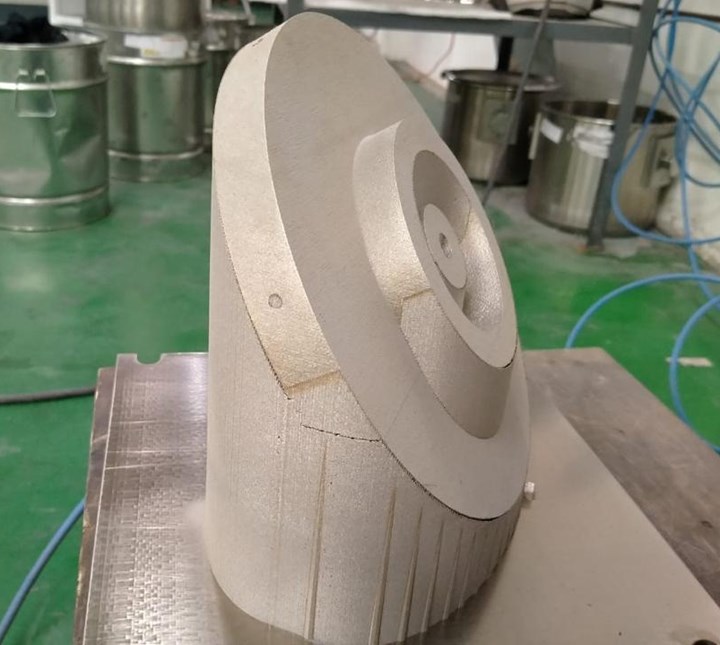

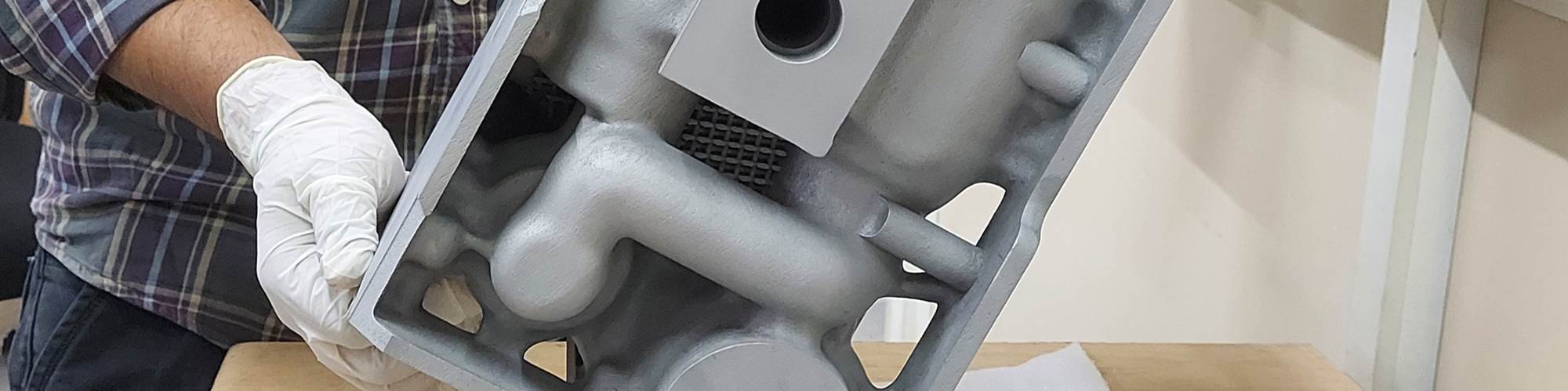

Years of development on this manifold for ISRO will be applied for any future manifolds the company might manufacture. Photo Credit: Objectify Technologies

A success in one type of component can be the grounds for others that are similar. In a recent case, Objectify produced a hydraulic manifold for the Indian Space Research Organization (ISRO). The original component weighed about 21 kg and was produced by drilling channels and machining down a solid block of aluminum. The company redesigned the component for laser powder bed fusion, again in an aluminum alloy. The redesign reduced the manifold’s weight by about 30% to 14.9 kg and thus allowed for an increased payload on the spacecraft, which has 12 of these parts.

The spacecraft carrying these parts launched in August 2022, but the 3 years spent developing them will inform Objectify’s work on similar components going forward. “Now we are going after other manifolds, like actuator manifolds for oil and gas,” Sahu says. Other part groupings the company is interested in include rocket injectors, brackets and heat exchangers.

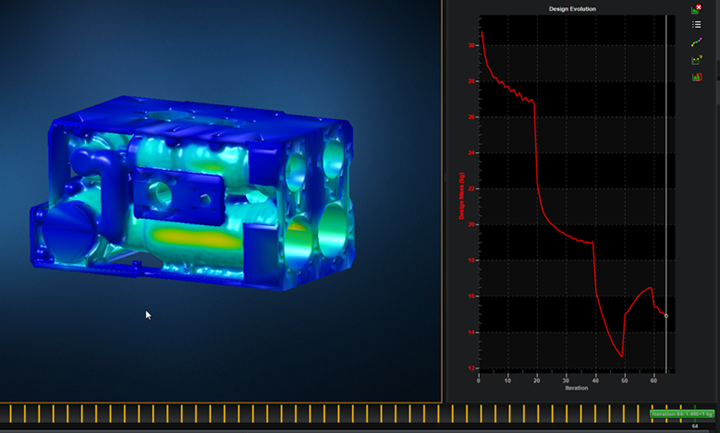

The design evolution for this manifold included a significant weight reduction, from 21 kg down to 14.9 kg. Lessons learned about lightweighting, performance efficiency and process optimization from this manifold will carry forward to other similar parts. Photo Credit: Objectify Technologies

4. Share successes whenever possible.

Like most manufacturers, much of what Objectify produces can’t be shown or described publicly. But examples like the manifold pictured above are particularly important, because they provide an illustration of what additive manufacturing can do. The company makes a point to publicize wins like this to help raise awareness of AM and educate potential customers about its capabilities.

“I believe the value created by additive manufacturing is higher than the cost of the technology.”

Ultimately, “awareness increases the availability for capital expenditure,” Sahu says. While the cost of an additively manufactured part may remain higher than conventionally made parts, buyers can be brought to see the benefits of making this investment.

“I believe the value created by additive manufacturing is higher than the cost of the technology,” Sahu says. “It’s still a journey for our customers, but also very exciting.”

Related Content

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreAircraft Engine MRO: How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair

AM offers the chance to bring fast, automated processing to individualized, part-by-part restoration of turbomachinery. A cell developed by Acme Manufacturing and Optomec is able to automatically repair 85,000 unique aircraft engine blades per year.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreRead Next

3D Printed Parts on the Mars Perseverance Rover: The Cool Parts Show #23

The Perseverance parts made through additive manufacturing are extreme examples of lightweighting. We have replicas of the 3D printed parts that were sent to Mars.

Read More8 Strategies to Drive Additive Manufacturing Adoption From Within an Organization

A panel discussion at RAPID + TCT 2021 brought valuable insights and ideas for advancing AM within large companies. The talk was organized by Women in 3D Printing.

Read MoreWhy Is There Reason for Optimism in Additive Manufacturing?

Implementing additive manufacturing is difficult and requires a significant pivot for an established manufacturer. Peter Zelinski and Stephanie Hendrixson discuss why making that pivot is worthwhile.

Read More

.jpg;width=70;height=70;mode=crop)