The transition to additive manufacturing (AM) is difficult for a business that already has an established product line and supply chain. Despite the advantages that can be achieved in time to market, design improvements, and supply chain shortening, it’s still a challenging proposition to change from the status quo.

But it’s a change worth executing, because of the potential benefits in business, manufacturing and life overall. In this portion of the AM Radio podcast, I ask cohost and editor-in-chief Peter Zelinski why he’s optimistic about additive manufacturing in spite of all its challenges. Listen above, or read on for the transcript.

Transcript

Stephanie Hendrixson

The AM Radio podcast is brought to you by the Additive Manufacturing Conference and Expo. The leading industry event focused on 3D printing for production. The conference takes a practical applications-based look at the machines, materials and methodologies being used to create and use tools and components. The event is designed for owners, executives and engineers in manufacturing as well as OEMs. involved in durable goods production. Join the additive manufacturing team in Cincinnati, Ohio for two days of in-depth conference sessions, exhibits and plenty of networking opportunities with am experts. Also on the expo floor, check out the finalist entries in the cool part showcase a contest to find the next subject of our video series. The cool part show, be sure to vote on your favorite. The Additive Manufacturing Conference and Expo runs October 12 through 14. Find all the details and register at AdditiveConference.com.

Okay, Pete. So we just had this whole conversation about realism and skepticism in additive manufacturing. But now I want to talk about optimism, because I've heard you say in different contexts, things like you believe in additive manufacturing. additive is the way forward for manufacturing. And I want to just kind of like get to the bottom of that. And why are you so optimistic. So I guess as a starting point, like you've spent most of your career as an editor of our sister publication, Modern Machine Shop, which is all about machining — subtractive manufacturing. And I want to start by just asking you like what was the experience or the moment that convinced you that additive manufacturing is for real?

Peter Zelinski

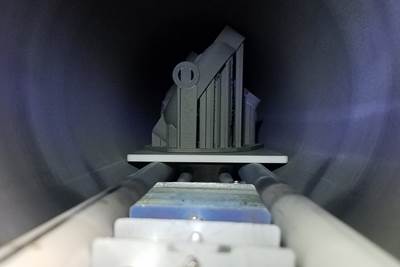

The moment boy, I don't know if there was a moment I feel like it's been sort of an a gradual process of figuring this stuff out. And I think I'm still doing that. And I think I'm still revising the picture. But if I'm going to point to one moment early on, it was CNA tool is this is this very successful machining business in northern Indiana. Churubusco, Indiana, and it's founded by this guy, Dick Conrow, who, who we just recently lost, he passed away maybe a year ago. But over the course of decades, he built up this very sophisticated, as I say, very successful CNC machining business. And he got into additive, to metal additive manufacturing, and I was visiting that facility to see the additive equipment. Let's say it was 2014. I might be getting that year wrong by one, but somewhere around then. And at that time, we were still wrestling with questions of what is really the place of 3D printing? Is it is it really just for prototypes, and one-offs and maybe some tooling? And there were plenty who were who were seeing a production role for it. And Dick Conrow was one who was seeing the production role, to the extent where he was using these EOS laser powder bed fusion machines. He had four of them I think at the time and was using them for nothing but production parts and just to end seeing him in his facility, seeing the parts he was producing for customers. And he was just thinking about this technology in an industrial way, in a production way. That that for someone who understood production and metalworking so well that it fit that model that he lived in mastered so well. I think I just saw it there and so some of the stuff he was wrestling with at that time uninterrupted power. He was he experienced the problem with that real time a lightning storm came in and ruined a job and like for a moment there his people turned into farmers they were like watching the horizon looking for rain showers to come before they had solved the power supply problem, something additive manufacturing they take for granted. And brackets. Dick Conrow was the first one who said to me, Pete, you know what, what this technology really wants to make? It wants to make brackets. And he explained all that to me and like how much do we love brackets?

Stephanie Hendrixson

So much. So okay, so this was kind of an early experience like 2014, thereabouts, like that's before I started writing for additive and to have a company out there that's doing metal production and dedicating machines to that, that is pretty unique for that time. And you sort of started describing some of the challenges that they were facing on interrupted power. We've talked about a lot of the other difficulties with additive. And I'm wondering, you know, if additive is so difficult to implement, and to get it right, like why is it still worth doing?

Peter Zelinski

I mean, what's not difficult to implement? I mean, life is hard, who hasn't noticed that? But why is it worth it? additive manufacturing's cost saving potential is so transformative. But you have to transform yourself to get there. And those kind of cost savings have to do with this. This more nimble, less hardware dependent, less inventory dependent, less advanced warning dependent way of producing that is vastly different from the way we organize production right now, and vastly liberating relative to all of the burdens and constraints that we take for granted in manufacturing now. And we're walking forward into this process of figuring out what kind of parts are possible in this new mode of production, and then the kinds of things we can do with it. And it's so promising that, like, I think the adventure is just beginning. Like that's why it's worth it that that adventure of finding out the new stuff we can invent and the new stuff we can produce.

Stephanie Hendrixson

So the adventure of finding out, I guess that's something I'm curious about, like this is a topic that we as the additive manufacturing brand have been covering for almost 10 years now. And production has certainly grown in that time production using additive manufacturing. But I'm wondering what are the hurdles that we're still trying to overcome? What are the reasons that people aren't adopting additive, and we're sort of getting there but I want to hear you kind of elaborate on that.

Peter Zelinski

So I heard this analogy once that's in a different, entirely different place. And it has to do with installing high-speed data cables, within neighborhoods, with connecting houses. And the and the analogy is the last mile problem. What you need to do to set up the network, it's pretty straightforward, broadly speaking, but then what you need to do to connect every individual house like that's where the difficulty really comes. And so part of it is, the obstacles you're describing part of it is that last mile problem in manufacturing. The additive capability is there. It is repeatable and resilient. And it can give us the products and properties that we want and almost any application we want to apply it to. But how do you make it work within the particular application that you want to master it in? And how do you convince all the stakeholders within that application that it does work, and it's giving you the product that everybody wants, and these are the kinds of challenges that are kind of knotty in the details and we're still working out and will take a while to work out. The other challenge is that the existing conventional manufacturing processes work pretty good, and work downright well for what they're trying to do for what we've asked them to do over the course of all these years. And it is pretty difficult and pretty expensive to run your established process at full output. And at the meantime, invent the future in parallel by running a different process that asks for different organization and almost a different structure of the enterprise. Yeah, in parallel with that. So in some ways the success of our existing current processes is a competitor. And it has a slowing effect on the adoption of additive.

Stephanie Hendrixson

Right. So getting past those incumbent processes and finding the pathway forward for additive is something that we're working through. I guess what I, what I haven't heard you say yet is like the real potential here for additive. Like go big picture. Why should companies make the investment in figuring this pivot out?

Peter Zelinski

We take for granted in industry today, that design engineering is one thing. And manufacturing, engineering is another thing, and even marketing and aftermarket support are other things all together. And what if there is a different way of thinking about production, and invention, and the enterprise in which all those things bleed together, and all of those things are nimble. And all of those things are happening at the same time and continuing to happen at the same time, all while the product is, is in the field and finding its customers. And what I mean by that is, it's no longer going to be necessary to lock in your design, at some point, have the design engineers all let go so that manufacturing can take over because tooling requires your design to be to be fixed and stable. What about a process and this is something I think we'll take for granted in the future. The product continues to get better as it's used in the field in the same way that our software we take for granted continues to get better as people use it in the field, keep on changing the design, because designs don't have to be fixed. And what we consider the cost of inventory today and logistics today. And preparing for aftermarket service today. What if all of those shelves full of stuff could be barren and all those warehouses didn't have to be filled and didn't have to take up space. Because we can print fast enough and print near enough to where the end use might be that we can create all these objects as they're needed and wait until the world gives us cues for what's needed and make them then all this stuff is strange. But it's a really powerful and really efficient. And both economically and resource conserving way to produce that is that is vastly different than what's possible for us now. To live and move and build your career and build your business in industry and manufacturing right now is to take a lot of burdens for granted. And all these burdens can be shed once additive manufacturing is adopted a lot more and gets a little better.

Stephanie Hendrixson

So lots of reasons for optimism in there. So I guess maybe as just kind of a wrap-up, last question here. Given everything that we've talked about today, the pessimism and the optimism, what advice would you give to manufacturers who are looking to adopt additive and to get into additive manufacturing?

Peter Zelinski

I will give you the answer that you expect and everyone says and then I'll give you a different answer that maybe we haven't heard before. So the answer everyone says, because it's true, is get some 3D printing capability and use it for your own internal needs, make tools with it. Make stuff that you can use around the facility with it. Tooling in particular. These are, these are parts, these are functional parts. And just the exercise of making tools, noncritical parts that customers don't have to see is going to teach the organization a whole lot about what additive can do and begin that process of unlearning design constraints and and beginning to to get engineers minds moving around within the freer and more open design space that additive permits.

The other advice I would give recognizes that within additive manufacturing, there is a big advantage to new entrants. New products that have never been made before have an advantage because there's no existing manufacturing process that has to be adapted or pivoted. And new companies coming into manufacturing have an advantage. Companies that have never done manufacturing before actually have an edge in additive manufacturing because they're not burdened say with an ongoing process that's also working well but they also have to support and that shapes the culture of the enterprise and the organization and the process. So the advice I would give is do you see a way? Do you see an opportunity to give yourself something like that new entrant edge, if there's a new product coming along an entirely new product addition for the company, a new addition, is there a way to produce that through 3D printing or with 3D printing bring significant advantages to that to that product? And if there is a way, lean hard into that and make it a 3D printed product, and pretend that your other processes don't exist. You'll need those other processes, but pretend they don't exist and require engineering to go seek them out as a newcomer would, and then turn the team around that product into a new entrant team as well try to do that. Put them into a space capsule somehow isolate them from the rest of the organization, not because the rest of the organization can't teach them something they absolutely can. But additive manufacturing requires a different organization and a different culture and deal with that and do everything that has to be done to deal with that let the team feel a sense of distance and mission and specialists and cohesion the way a group of new entrants would, because otherwise, the pull of gravity and inertia of the strength and establishment of the existing organization is going to impede what you're trying to do with additive manufacturing. So yes, send it out into a space capsule, send it out into a boat, let it make the new product that way, and then bring it back in when it starts to succeed.

Stephanie Hendrixson

Yeah, so it's almost getting back to that like skunkworks idea where you have facility within a facility or group within a group.

Peter Zelinski

The skunkworks idea, totally. I guess I like my spacecraft imagery a little better. But totally.

Stephanie Hendrixson

I mean, we can, we can stick with that we'll end with that. And Pete, is there any anywhere that you'd like to direct our listeners to learn more information?

Peter Zelinski

You've hinted at a couple things we've posted on AdditiveManufacturing.Media. I posted a commentary recently about reasons why I'm bullish about additive, it sort of gets into the obstacles at this point are largely numbers. And that argument might be interesting to people who are thinking about causes for optimism and additive manufacturing are younger people who are maybe thinking about where their career should go with it industry or within manufacturing. Oh, you know where else they could go is there was that piece that we published a while ago, a long piece, it's called “What Your CEO Should Know.” And it's about ways the enterprise, the whole enterprise, not just manufacturing, needs to change to make good use of additive manufacturing. And that's a that's a piece we keep on recommending to companies that are struggling with this particularly larger companies thinking about how to think about additive manufacturing.

Stephanie Hendrixson

Yeah, that's a really good resource and we'll put links to both of those in the show notes. I think that's it for today's show.

AM Radio is recorded with help from Austin Grogan and Kade Nicholson. The show is edited by me Stephanie Hendrixson, along with Alex Lytle, and Troy Brewer. Our artwork is by Kate Billberry. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in the Queen City, Cincinnati, Ohio. I'm Stephanie Hendrixson. Thanks for listening

Related Content

Additive Manufacturing Production at Scale Reveals the Technology's Next Challenges: AM Radio #28

Seemingly small issues in 3D printing are becoming larger problems that need solutions as manufacturers advance into ongoing production and higher quantities with AM. Stephanie Hendrixson and Peter Zelinski discuss 6 of these challenges on AM Radio.

Read MoreThe Arrival of the AM Factory: How Proprietary Processes Deliver Production 3D Printing

Various recent articles report on companies using internally developed technology to equip factories and deliver on the promise of AM for production.

Read MoreFour Ways This Additive Manufacturer Counters Risk Aversion

3D printing service bureau Objectify Technologies uses four globally-applicable strategies to help potential and current customers overcome the barriers to additive manufacturing adoption.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreRead Next

How Additive Manufacturing Is Like (and Different from) CNC Machining

A leading machining business applies the skill of a toolmaker to using additive manufacturing effectively. The manufacturer shares application examples, as well as thoughts on the challenge and promise of this technology.

Read MoreWhat Should We Call Additive Manufacturing Businesses? AM Radio #3

Machining is done in a shop, injection molding is done at a molder and casting is done at a foundry. But what do we call businesses that do additive manufacturing? Peter Zelinski and Julia Hider discuss why it’s difficult to name these businesses (and suggest a few options) on this episode of AM Radio.

Read MoreWhy I Am Bullish on Additive: 3 Factors Favoring 3D Printing’s Continued Advance

The shortcomings are being overcome and the advantage is nothing less than freedom. Only the pace of the advance is uncertain.

Read More

.jpg;width=70;height=70;mode=crop)